Radix gentianae compound enzyme as well as preparation method and application thereof

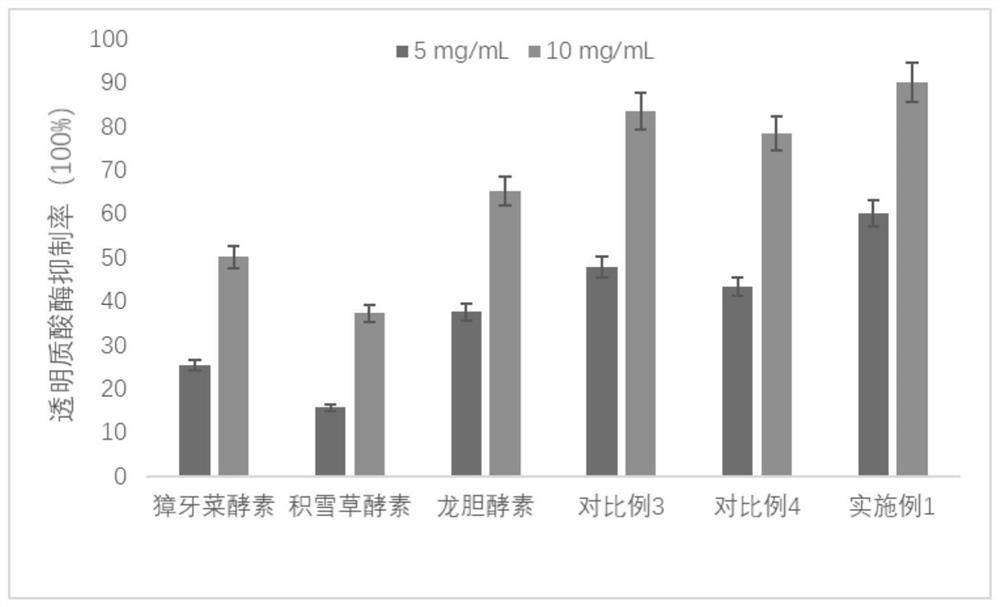

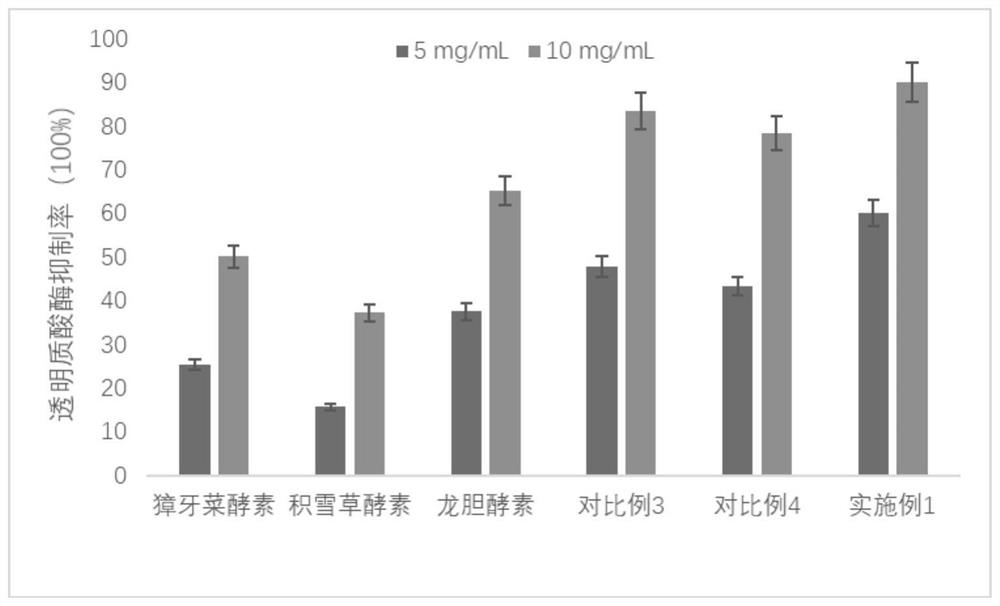

A compound and enzyme technology, applied in the field of gentian compound enzyme and its preparation, can solve problems such as poor use effect and low content of effective substances, and achieve the effects of improving skin condition, reducing toxicity and clarifying the mechanism of drug action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

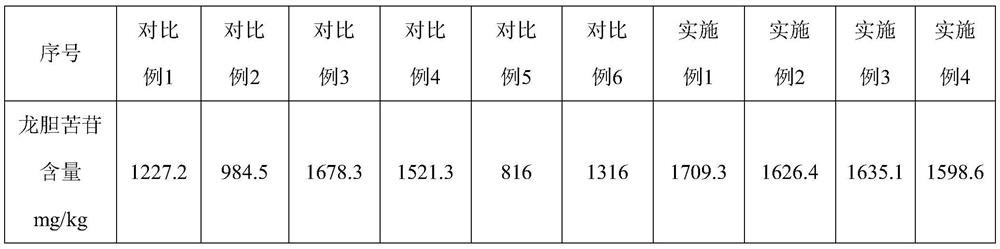

Embodiment 1

[0033] The preparation method of the gentian compound ferment of the present embodiment comprises the following steps:

[0034] 1. Weigh 10 parts of fresh gentian, 5 parts of watercress, and 5 parts of Centella asiatica by weight, crush them, pass through an 80-mesh sieve, add deionized water 3 times the weight of the powder to dissolve, and prepare a solution ;

[0035] 2. Add 0.5% cellulase and 0.5% pectinase to the solution, and treat for 60-120 minutes to obtain an enzymatic solution;

[0036] 3. Add 1% Yeast Extract (yeast extract), 2% Peptone (peptone), 2% Dextrose (glucose) (glucose) of the mass of the enzymolysis solution to the enzymolysis solution and transfer to a bioreactor for sterilization at 115°C for 15 minutes. Prepare a sterilizing solution;

[0037] 4. In the sterilization solution, according to the strain combination of Saccharomyces cerevisiae and Lactobacillus plantarum 1:1, the inoculation amount is 10% to insert the strains

[0038] 5. Set the fermen...

Embodiment 2

[0040] The preparation method of the gentian compound ferment of the present embodiment comprises the following steps:

[0041] 1. Take 8 parts by weight of fresh gentian, 4 parts of watercress, and 4 parts of Centella asiatica, crush them, pass through an 80-mesh sieve, add deionized water 3 times the weight of the powder to dissolve, and prepare a solution ;

[0042]2. Add 0.5% cellulase and 0.5% pectinase to the solution, and treat for 60-120 minutes to obtain an enzymatic solution;

[0043] 3. Add 1% Yeast Extract (yeast extract), 2% Peptone (peptone), 2% Dextrose (glucose) (glucose) of the mass of the enzymolysis solution to the enzymolysis solution and transfer to a bioreactor for sterilization at 115°C for 15 minutes. Prepare a sterilizing solution;

[0044] 4. In the sterilization solution, according to the strain combination of Saccharomyces cerevisiae and Lactobacillus plantarum 1:1, the inoculation amount is 10% to insert the strains

[0045] 5. Set the fermentat...

Embodiment 3

[0047] The preparation method of the gentian compound ferment of the present embodiment comprises the following steps:

[0048] 1. Weigh 6 parts of fresh gentian, 5 parts of watercress, and 5 parts of Centella asiatica by weight, crush them, pass through an 80-mesh sieve, add deionized water 3 times the weight of the powder to dissolve, and obtain a solution ;

[0049] 2. Add 0.5% cellulase and 0.5% pectinase to the solution, and treat for 60-120 minutes to obtain an enzymatic solution;

[0050] 3. Add 1% Yeast Extract (yeast extract), 2% Peptone (peptone), 2% Dextrose (glucose) (glucose) of the mass of the enzymolysis solution to the enzymolysis solution and transfer to a bioreactor for sterilization at 115°C for 15 minutes. Prepare a sterilizing solution;

[0051] 4. In the sterilization solution, according to the strain combination of Saccharomyces cerevisiae and Lactobacillus plantarum 1:1, the inoculation amount is 10% to insert the strains

[0052] 5. Set the fermenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com