Galvanized steel pipe manufacturing and machining cut-off machine

A galvanized steel pipe and cutting machine technology, applied in the direction of manufacturing tools, metal processing machinery parts, other manufacturing equipment/tools, etc., can solve the problems of damage to heated blades, increase costs, affect production, etc. The effect of insufficient cutting and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

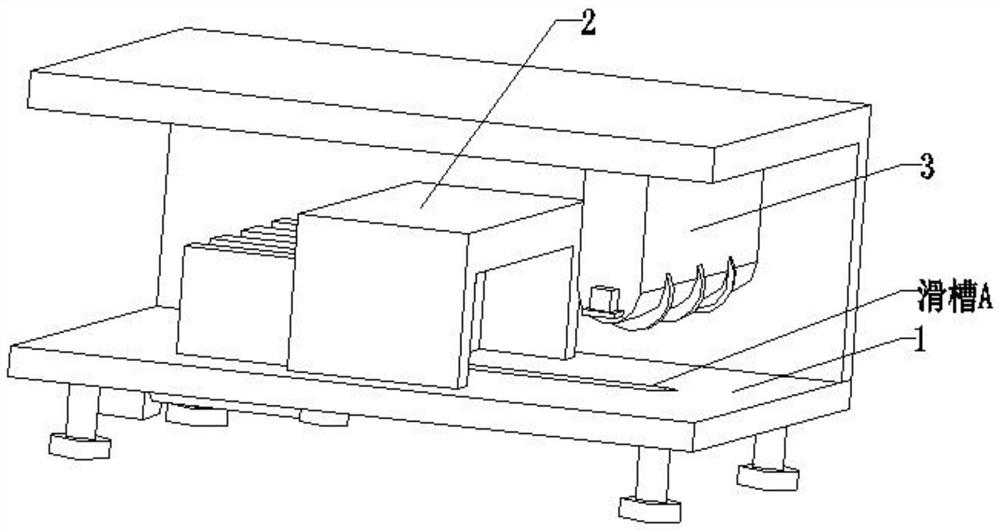

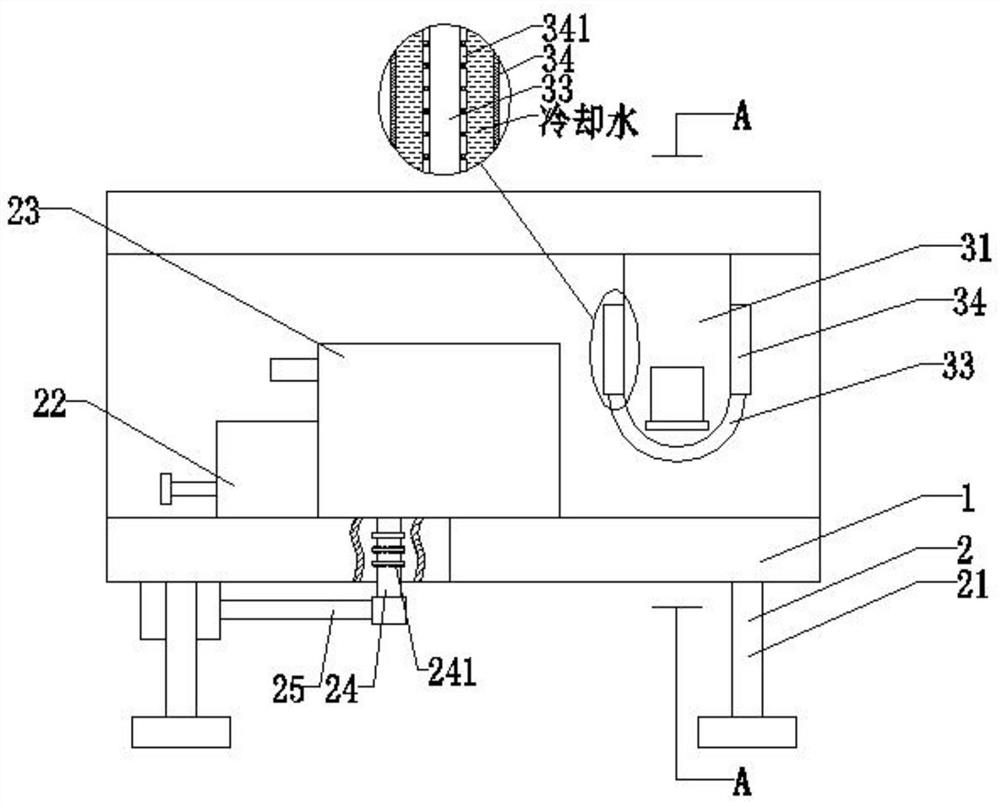

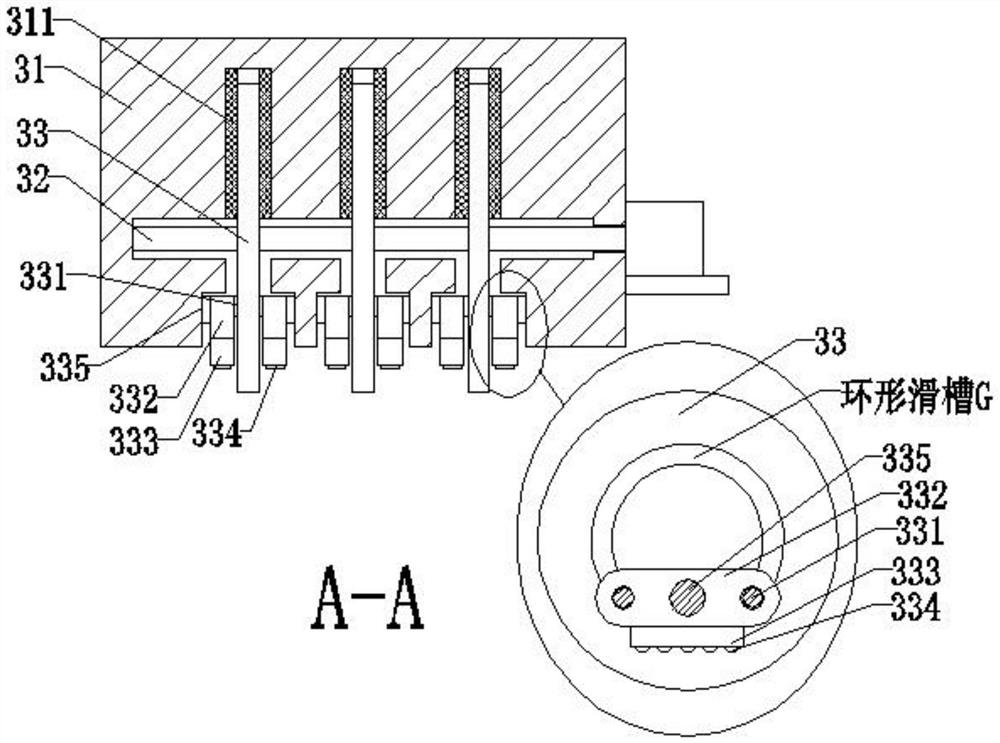

[0026] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 6 , to further elaborate the present invention.

[0027] A galvanized steel pipe manufacturing and processing cutting machine, including a mounting frame 1, a clamping component 2 and a cutting component 3, a chute A is provided on the mounting frame 1, a clamping component 2 is installed on the mounting frame 1, and the upper end of the clamping component 2 is A cutting assembly 3 is provided, and the cutting assembly 3 is fixedly installed on the installation frame 1, wherein:

[0028] The clamping assembly 2 includes a supporting column 21, a charging frame 22, a pressing frame 23, a connecting block 24, a draw bar 25 and a No. 1 cylinder, and the supporting column 21 is evenly installed on the lower end surface of the mounting frame 1 by welding. A charging frame 22 is installed on the mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com