Gladiolus flower-like nickel selenide/cobalt selenide/nickel diselenide nanocomposite array electrode material

A nanocomposite, array electrode technology, applied in metal selenide/tellurium, selenium/tellurium compound, hybrid capacitor electrodes, etc., to achieve high efficiency, enhanced electrochemical performance, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

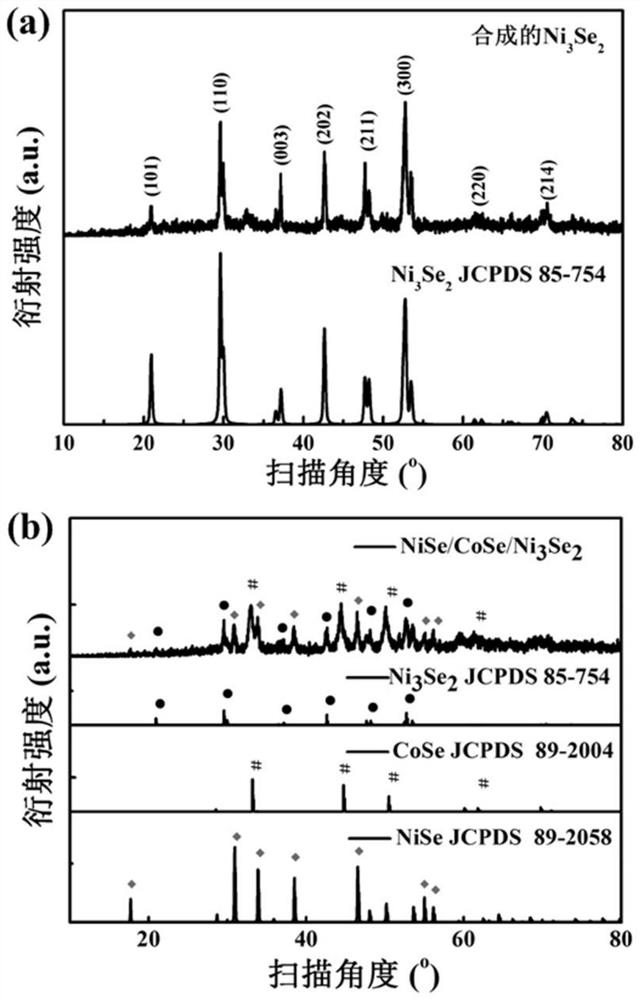

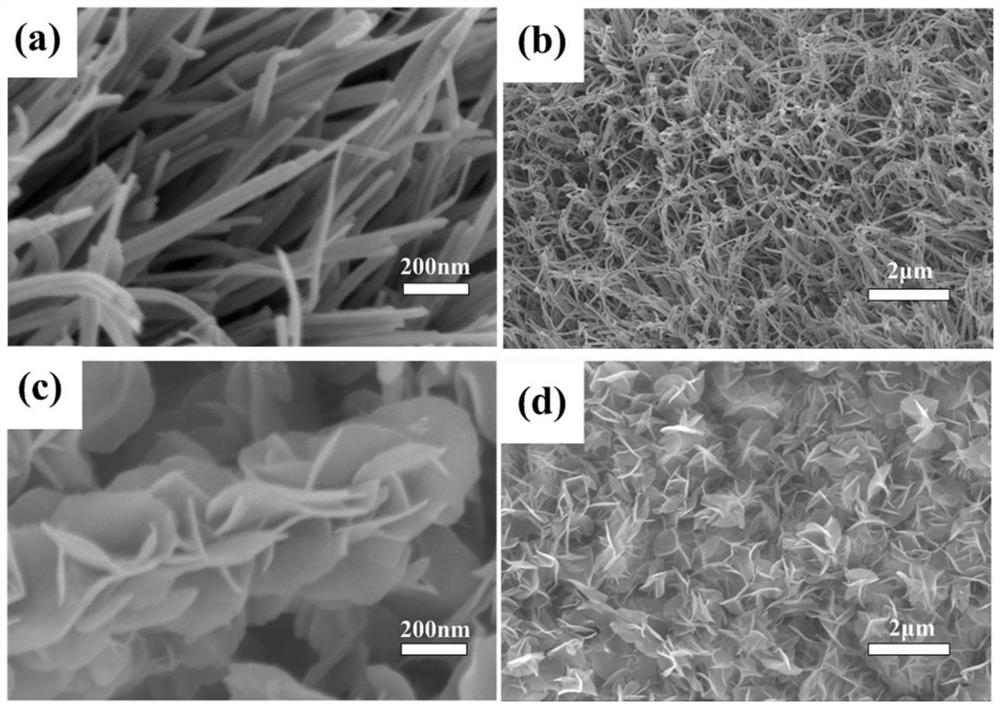

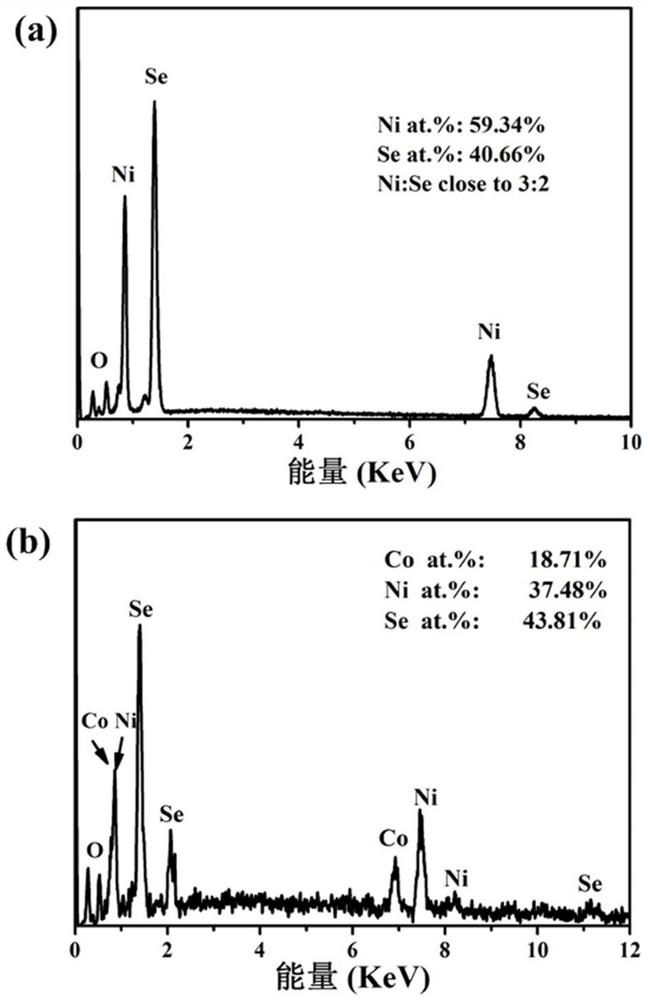

[0025] ①Add 0.15mmol of Se powder to 15mL of ethylenediamine, add pretreated nickel foam (10mm*40mm*1.5mm) after the Se powder is dissolved, put it in a 25mL reaction kettle with PTFE lining for 180 ℃ hydrothermal treatment, after the reaction, the reaction kettle is naturally cooled, the reacted nickel foam is washed with ethanol, and dried in vacuum to obtain Ni 3 Se 2 Nanowire Array Precursors.

[0026] ② 0.16 mmol of cobalt acetate tetrahydrate was added to a mixed solvent of anisole and methanol (12 mL of anisole and 4 mL of methanol), heated for 30 minutes, and dissolved to prepare a mixed solvent reaction solution.

[0027] 3. The mixed solvent reaction solution of step (2) is transferred into the 25mL autoclave with polytetrafluoroethylene lining, and the Ni synthesized in step (1) is added. 3 Se 2 The nanowire array precursor template was sealed and solvothermally treated at 120°C for 6 hours, and cooled naturally after the reaction. The obtained product was washe...

Embodiment 2

[0031] ①Add 0.15mmol of Se powder to 15mL of ethylenediamine, add pretreated nickel foam (10mm*40mm*1.5mm) after the Se powder is dissolved, put it in a 25mL reaction kettle with PTFE lining for 180 ℃ hydrothermal treatment, after the reaction, the reaction kettle is naturally cooled, the reacted nickel foam is washed with ethanol, and dried in vacuum to obtain Ni 3 Se 2 Nanowire Array Precursors.

[0032] ② 0.20 mmol of cobalt acetate tetrahydrate was added to 16 mL of mixed solvent (13 mL of anisole and 3 mL of methanol), heated for 30 minutes, and dissolved to prepare a mixed solvent reaction solution.

[0033] 3. The mixed solvent reaction solution of step (2) is transferred into the 25mL autoclave with polytetrafluoroethylene lining, and the Ni synthesized in step (1) is added. 3 Se 2 The nanowire array precursor template was sealed and solvothermally treated at 100°C for 8 hours, and cooled naturally after the reaction. The obtained product was washed with ethanol an...

Embodiment 3

[0036] ①Add 0.15mmol of Se powder to 15mL of ethylenediamine, add pretreated nickel foam (10mm*40mm*1.5mm) after the Se powder is dissolved, put it in a 25mL reaction kettle with PTFE lining for 180 ℃ hydrothermal treatment, after the reaction, the reaction kettle is naturally cooled, the reacted nickel foam is washed with ethanol, and dried in vacuum to obtain Ni 3 Se 2 Nanowire Array Precursors.

[0037] ② 0.32 mmol of cobalt acetate tetrahydrate was added to 16 mL of mixed solvent (14 mL of anisole and 2 mL of methanol), heated for 30 minutes, and dissolved to prepare a mixed solvent reaction solution.

[0038] 3. The mixed solvent reaction solution of step (2) is transferred into the 25mL autoclave with polytetrafluoroethylene lining, and the Ni synthesized in step (1) is added. 3 Se 2 The nanowire array precursor template was sealed and solvothermally treated at 140°C for 6 hours, and cooled naturally after the reaction. The obtained product was washed with ethanol an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com