Luminescent material based on cerium and europium activated aluminosilicate and preparation method and application thereof

A technology of luminescent materials and activators, applied in luminescent materials, chemical instruments and methods, thermometers with physical/chemical changes, etc., can solve problems that need to be further explored, and achieve fast response optical temperature measurement and high-sensitivity optical temperature measurement , the effect of strong luminous brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

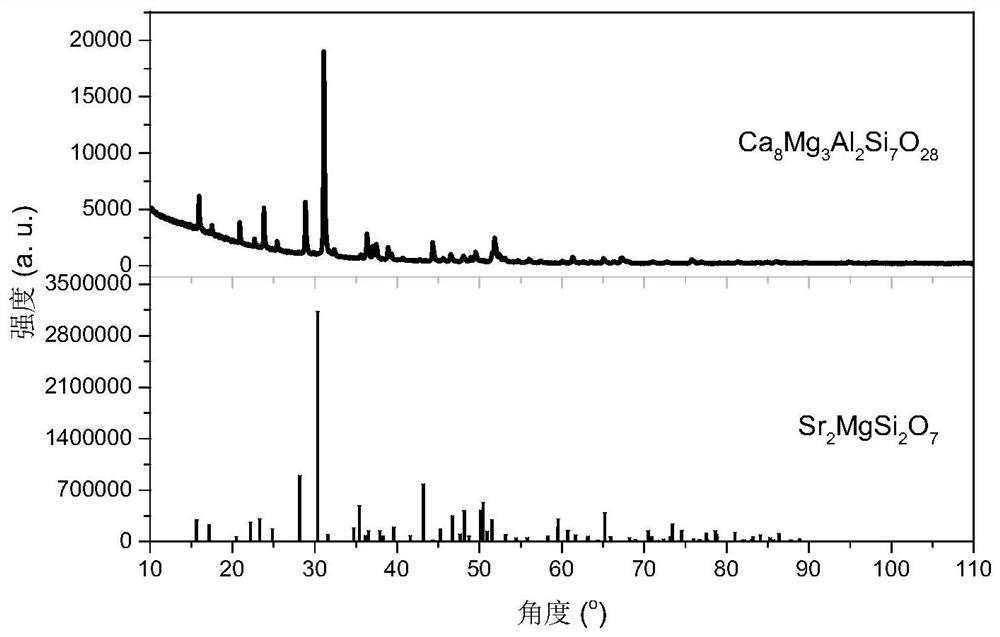

[0042] Ca 8 Mg 3 al 2 Si 7 o 28 The preparation method of matrix, comprises the steps:

[0043] Weigh calcium carbonate (CaCO 3 ) 0.8007g, magnesium oxide (MgO) 0.1209g, silicon dioxide (SiO 2 ) 0.4206g, aluminum oxide (Al 2 o 3 ) 0.1020g and boric acid (H 3 BO 3 ) 0.0450g, put in an agate mortar, add 5-10mL of absolute ethanol, grind for 20min, mix evenly and dry, put it into a corundum crucible, put it in a box furnace, and gradually heat up from room temperature to Calcined at 1260°C in a hot carbon reducing atmosphere (carbon monoxide), and continued to be calcined at a constant temperature for 6 hours, then the sample was naturally cooled and annealed to room temperature in the furnace, and the sample was taken out and ground to obtain the product.

Embodiment 2

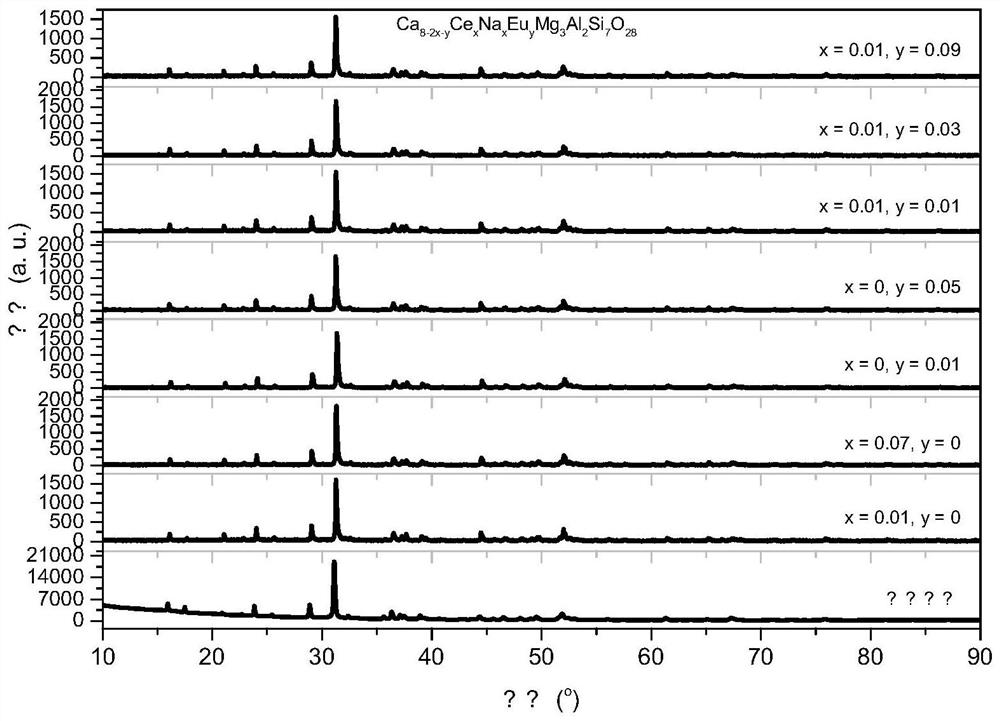

[0045] Ca 7.98 Ce 0.01 Na 0.01 Mg 3 al 2 Si 7 o 28 The preparation method of the material: weigh calcium carbonate (CaCO 3 ) 0.7987g, magnesium oxide (MgO) 0.1209g, silicon dioxide (SiO 2 )0.4206 g, aluminum oxide (Al 2 o 3 ) 0.1020g, boric acid (H 3 BO 3 )0.0450g, cerium oxide (CeO 2 )0.0017g and sodium carbonate (Na 2 CO 3 ) 0.0005g, put it in an agate mortar, add 5-10mL of absolute ethanol, grind for 20min, mix well and dry it, put it into a corundum crucible, put it in a box furnace, and gradually heat it up from room temperature to 1260°C, calcined in a hot carbon reducing atmosphere (carbon monoxide), and continued to calcined at a constant temperature for 6 hours, then the sample was naturally cooled and annealed to room temperature in the furnace, and the sample was taken out and ground to obtain the product.

Embodiment 3

[0047] Ca 7.94 Ce 0.03 Na 0.03 Mg 3 al 2 Si 7 o 28 The preparation method of the material: weigh calcium carbonate (CaCO 3 ) 07947g, magnesium oxide (MgO) 0.1209g, silicon dioxide (SiO 2 )0.4206 g, aluminum oxide (Al2 o 3 ) 0.1020g, boric acid (H 3 BO 3 )0.0450g, cerium oxide (CeO 2 ) 0.0052g and sodium carbonate (Na 2 CO 3 ) 0.0016g, put it in an agate mortar, add 5-10mL of absolute ethanol, grind for 20min, mix well and dry it, put it into a corundum crucible, put it in a box furnace, and gradually heat it up from room temperature to 1260°C, calcined in a hot carbon reducing atmosphere (carbon monoxide), and continued to calcined at a constant temperature for 6 hours, then the sample was naturally cooled and annealed to room temperature in the furnace, and the sample was taken out and ground to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com