Wear-resistant brake pad and processing method thereof

A brake pad and wear-resistant technology, applied in chemical instruments and methods, friction linings, and other chemical processes, can solve problems such as unstable friction coefficient, large wear, and poor stability of high-temperature friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

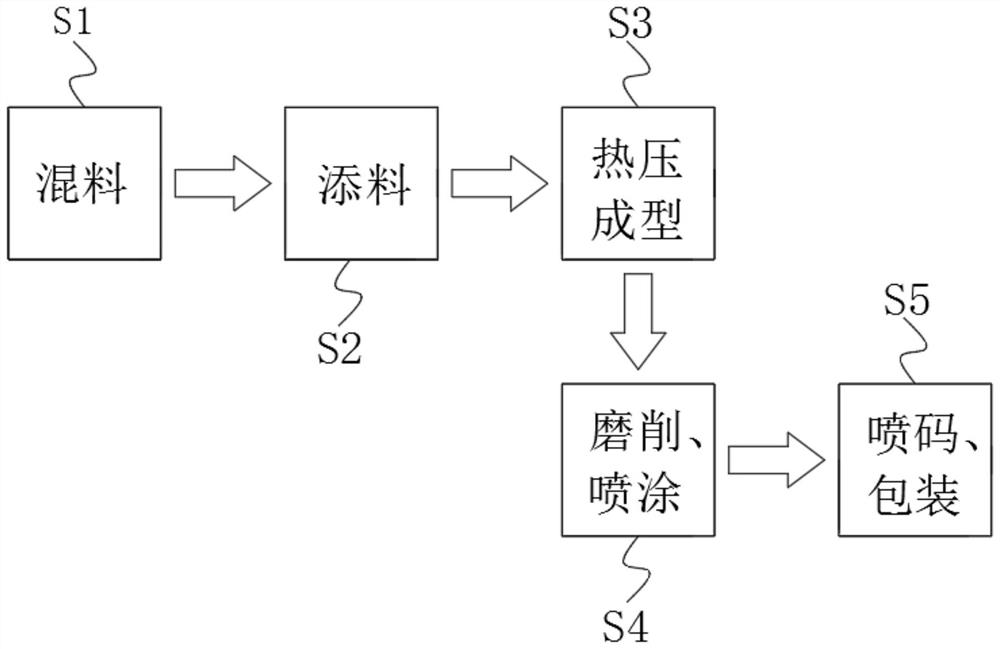

Image

Examples

Embodiment 1

[0026] The raw materials include by weight: 3 parts of aramid pulp, 2.5 parts of nitrile rubber powder, 7.5 parts of cashew nut shell oil friction powder, 2 parts of boron phenolic resin, 3 parts of corrosion resistance agent, 1.5 parts of stabilizer, 30 parts of ceramic fiber, 20 parts of natural cellulose fiber.

[0027] In the embodiment of the present invention, the anticorrosion agent is iron oxide green, which is a reactant of ferrous oxide and ferric oxide, and is a green or red-green fine solid particle.

[0028] In the embodiment of the present invention, the stabilizer is ultra-fine iron oxide powder, and the iron oxide powder is ground into solid particles with a diameter of 0.1 um by a pulverizer.

[0029] The invention also discloses a method for processing a wear-resistant brake pad, which specifically includes the following steps:

[0030] S1. Mixing: Select the material of the brake pads according to the proportion for mixing, pour aramid pulp, nitrile rubber ...

Embodiment 2

[0037] The raw materials include by weight: 5 parts of aramid pulp, 3.5 parts of nitrile rubber powder, 9.5 parts of cashew nut shell oil friction powder, 4 parts of boron phenolic resin, 6 parts of corrosion resistance agent, 3.5 parts of stabilizer, 40 parts of ceramic fiber, 30 parts of natural cellulose fiber.

[0038] In the embodiment of the present invention, the anti-corrosion agent is iron oxide green, which is a reactant of ferrous oxide and ferric oxide, and is a green or red-green fine solid particle.

[0039] In the embodiment of the present invention, the stabilizer is ultra-fine iron oxide powder, and the iron oxide powder is ground into solid particles with a diameter of 0.4um by a pulverizer.

[0040] The invention also discloses a method for processing a wear-resistant brake pad, which specifically includes the following steps:

[0041] S1. Mixing: Select the material of the brake pads according to the proportion for mixing, pour aramid pulp, nitrile rubber ...

Embodiment 3

[0048] The raw materials include by weight: 7 parts of aramid pulp, 4.5 parts of nitrile rubber powder, 11.5 parts of cashew nut shell oil friction powder, 6 parts of boron phenolic resin, 9 parts of corrosion resistance agent, 5.5 parts of stabilizer, 50 parts of ceramic fiber, 40 parts of natural cellulose fiber.

[0049] In the embodiment of the present invention, the anticorrosion agent is iron oxide green, which is a reactant of ferrous oxide and ferric oxide, and is a green or red-green fine solid particle.

[0050] In the embodiment of the present invention, the stabilizer is ultrafine iron oxide powder, which is ground into solid particles with a diameter of 0.6 um by a pulverizer.

[0051] The invention also discloses a method for processing a wear-resistant brake pad, which specifically includes the following steps:

[0052] S1. Mixing: Select the material of the brake pads according to the proportion for mixing, pour aramid pulp, nitrile rubber powder, cashew nut s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com