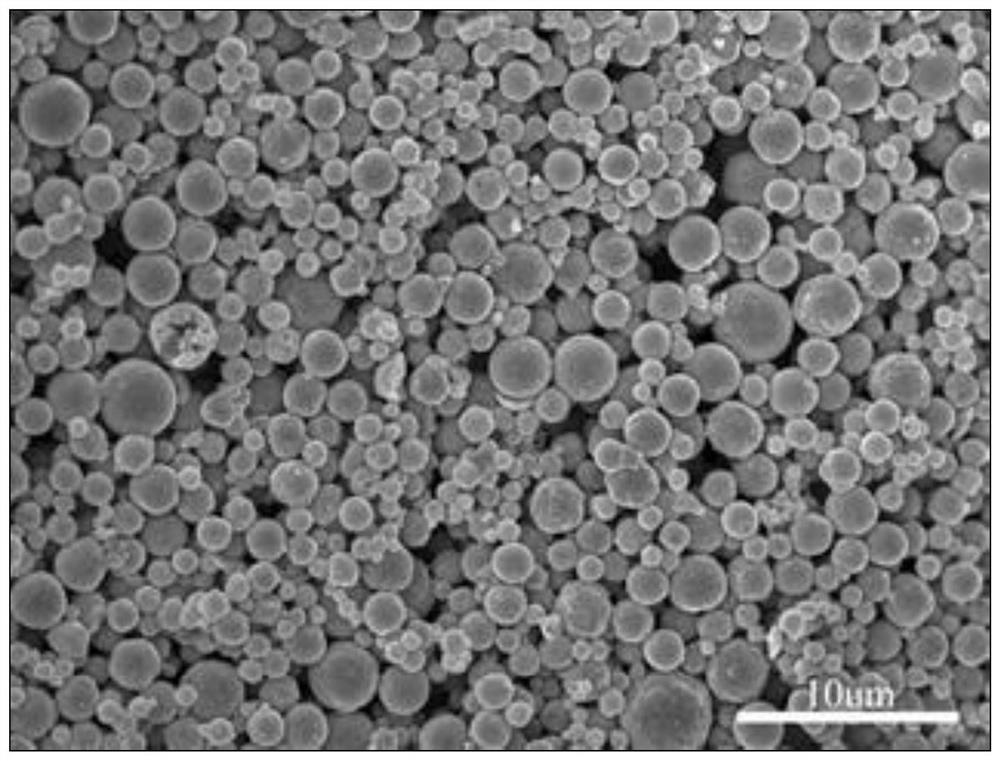

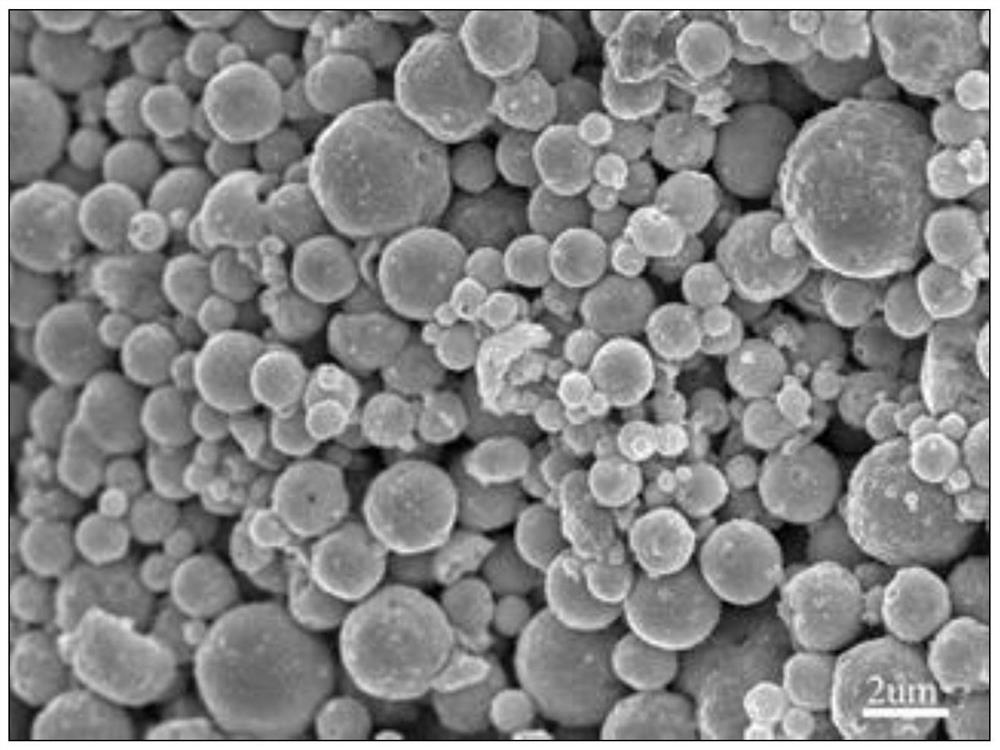

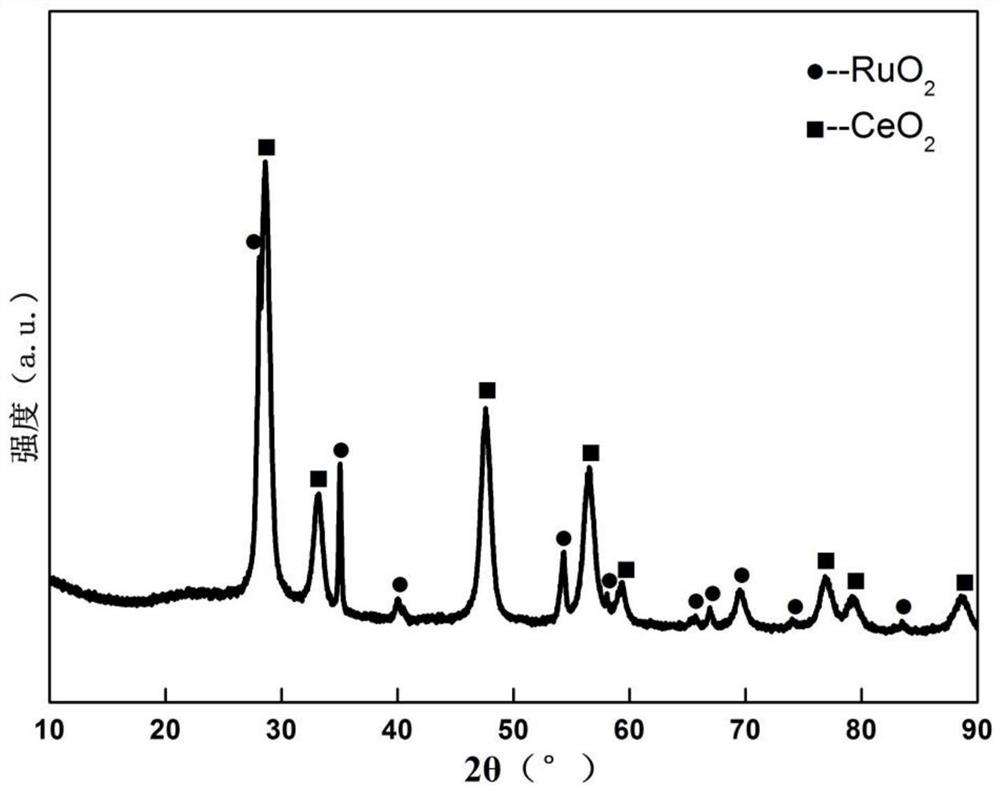

Preparation method of porous ruthenium dioxide-cerium dioxide microsphere composite material

A technology of ruthenium dioxide and ceria, which is applied in the field of preparation of porous ruthenium dioxide-ceria microsphere composite materials, can solve the problems of low yield and low product quality, achieve simple preparation methods and improve catalytic activity , the effect of improving transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment includes the following steps:

[0029] Step 1. Put RuCl 3 , RuCl 3 and NH 4 Cl is dissolved in deionized water to obtain a mixed salt solution; the solute RuCl in the mixed salt solution 3 , RuCl 3 and NH 4The total mass concentration of Cl is 10 g / L, and NH 4 The mass of Cl is 20% of the total mass of the solute, and the molar ratio of ruthenium to cerium is 3:10;

[0030] Step 2, adding the mixed salt solution obtained in step 1 into a spray dryer at a constant feeding rate for atomization drying to obtain mixed salt powder; the feeding rate of the mixed salt solution is 150 mL / h, and the atomization drying The temperature is 250℃;

[0031] Step 3: Put the mixed salt powder obtained in Step 2 into a tube furnace for calcination and oxidation treatment to obtain a porous ruthenium dioxide-ceria microsphere composite material; the process of the calcination and oxidation treatment is as follows: in an air atmosphere , heated to 650°C at a rate of...

Embodiment 2

[0036] This embodiment includes the following steps:

[0037] Step 1. Put RuCl 3 , Ce(NO 3 ) 3 and NH 4 Cl is dissolved in deionized water to obtain a mixed salt solution; the solute RuCl in the mixed salt solution 3 , Ce(NO 3 ) 3 and NH 4 The total mass concentration of Cl is 5 g / L, and NH 4 The mass of Cl is 20% of the total mass of the solute, and the molar ratio of ruthenium to cerium is 1:1;

[0038] Step 2, adding the mixed salt solution obtained in step 1 into a spray dryer at a constant feed rate for atomization drying to obtain mixed salt powder; the feed rate of the mixed salt solution is 250 mL / h, and the atomization drying The temperature is 300℃;

[0039] Step 3: Put the mixed salt powder obtained in Step 2 into a tube furnace for calcination and oxidation treatment to obtain a porous ruthenium dioxide-ceria microsphere composite material; the process of the calcination and oxidation treatment is as follows: in an air atmosphere , heated to 650°C at a ra...

Embodiment 3

[0041] This embodiment includes the following steps:

[0042] Step 1. Put RuCl 3 , Ce(NO 3 ) 3 and NH 4 Cl is dissolved in deionized water to obtain a mixed salt solution; the solute RuCl in the mixed salt solution 3 , Ce(NO 3 ) 3 and NH 4 The total mass concentration of Cl is 40 g / L, and NH 4 The mass of Cl is 20% of the total mass of the solute, and the molar ratio of ruthenium to cerium is 1:7;

[0043] Step 2, adding the mixed salt solution obtained in step 1 into a spray dryer at a constant feeding rate for atomization drying to obtain mixed salt powder; the feeding rate of the mixed salt solution is 50 mL / h, and the atomization drying The temperature is 200℃;

[0044] Step 3: Put the mixed salt powder obtained in Step 2 into a tube furnace for calcination and oxidation treatment to obtain a porous ruthenium dioxide-ceria microsphere composite material; the process of the calcination and oxidation treatment is as follows: in an air atmosphere , heated to 650°C a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com