Method for preparing boron alkene with high crystallinity and uniform thickness by hydrochloric acid assisted liquid phase oxidation

A high crystallinity, auxiliary liquid technology, applied in the direction of boron, boron/boride, etc., can solve the problem of poor removal of magnesium ions between layers, and achieve the effect of low method cost and simple and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Add 2.54g (10mmol) of elemental iodine into 300mL of acetonitrile, stir rapidly until it is completely dissolved, then continue to add 0.46g (10mmol) of magnesium diboride under nitrogen atmosphere, and stir well to obtain a precursor dispersion.

[0033] 2. Under nitrogen protection and stirring conditions, add 3mL of hydrochloric acid with a mass fraction of 36% to the precursor dispersion solution dropwise, react in the dark at room temperature for 14 days, then centrifuge at 15000r / min for 20min, collect the lower precipitate and redisperse In 20 mL of acetonitrile, shake and wash and centrifuge again, repeating this step 5 times. Subsequently, it was washed and centrifuged three times with deoxygenated deionized water and absolute ethanol respectively to obtain a solid substance.

[0034] 3. Take 25 mg of the solid substance obtained in step 2 and disperse it in 50 mL of acetonitrile, and use a probe to sonicate the dispersion for 120 min, and the ultrasonic pow...

Embodiment 2

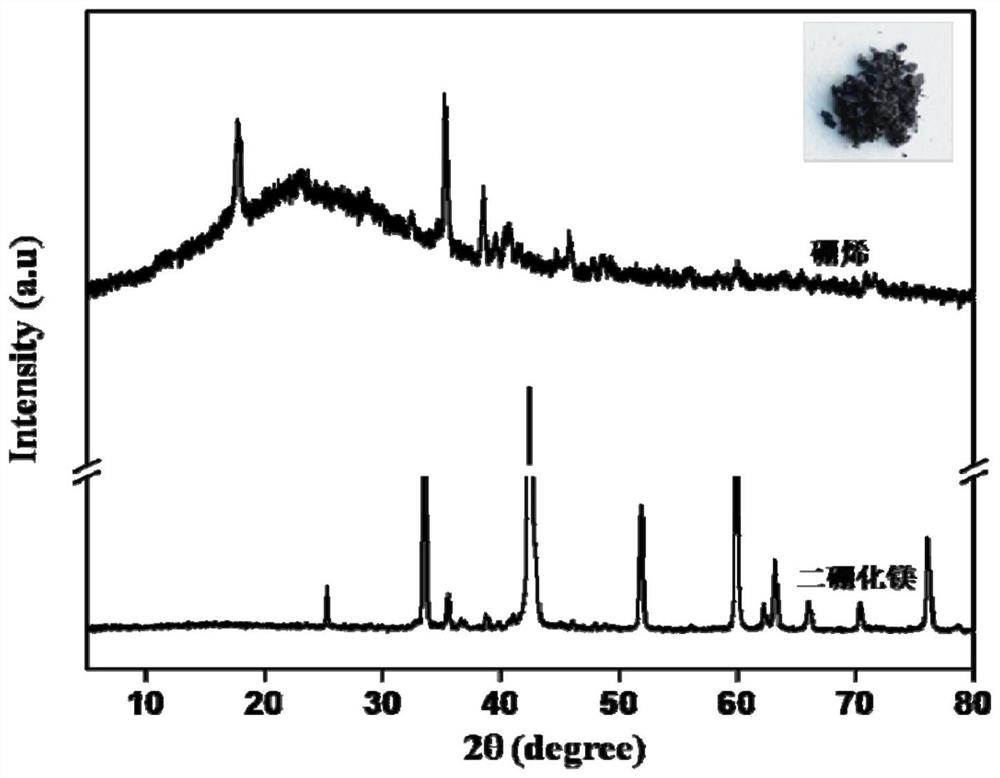

[0041] In step 2 of Example 1, the time for the light-shielding reaction was replaced by 7 days, 14 days, and 21 days in turn, and other steps were the same as in Example 1 to obtain corresponding products. From Figure 12It can be seen that when the reaction time reaches 7 days, the characteristic diffraction peaks of magnesium diboride disappear completely, and the (104) and (208) two groups of parallel crystal plane diffraction peaks of boron appear. After 14 days of reaction, the intensity of the above-mentioned parallel crystal plane diffraction peaks is the highest, and the rest of the diffraction peaks are few, and the effect is the best. After 21 days of reaction, the diffraction peak of (208) crystal plane gradually disappeared, accompanied by the appearance of other diffraction peaks, which proved that the effect of 14 days of reaction was the best.

Embodiment 3

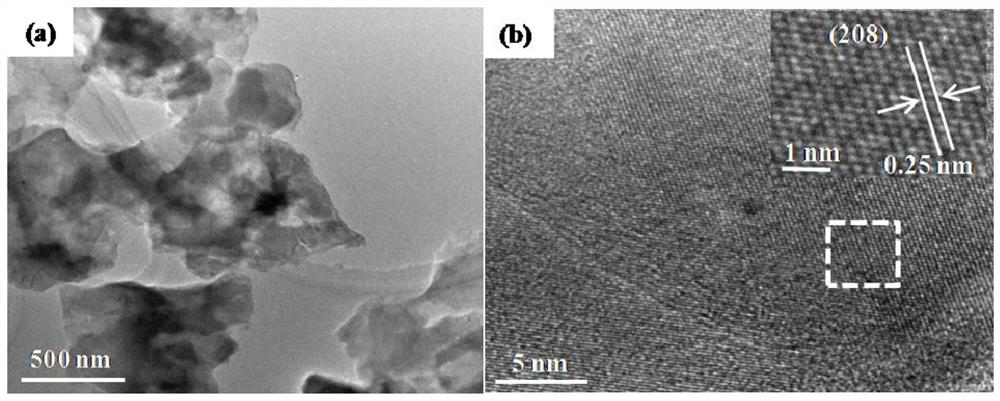

[0043] In step 3 of Example 1, the ultrasonic time was replaced by 60 min, 90 min, 120 min, and 150 min in turn, and other steps were the same as in Example 1 to obtain the corresponding product. From Figure 13 It can be seen that the edge of the product obtained after 60 min is partially thinned, but the central area is still in the shape of a block. After 120 minutes, the product showed a uniform flake shape, and the effect was good. After 180min, the lateral size of the obtained product gradually decreases, which is related to the fragmentation of boron nanosheets by long-time ultrasonication. Therefore, in the present invention, the preferred ultrasonic time is 90 to 150 minutes, and the effect of ultrasonic 120 minutes is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com