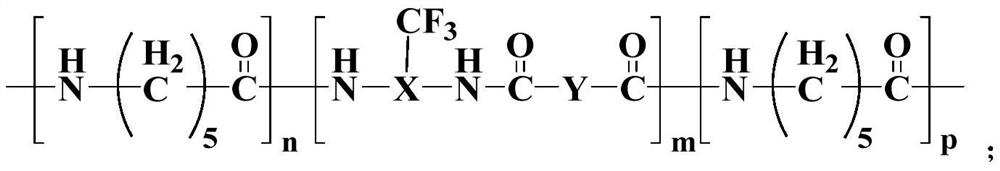

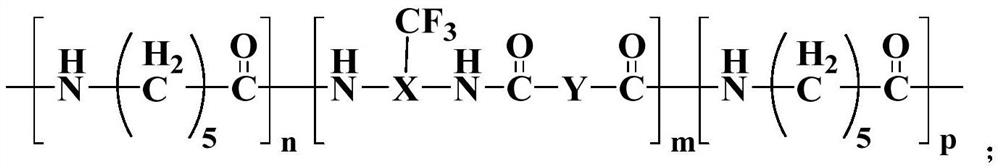

Fluorine-containing water-resistant polyamide 6 and preparation method thereof

A technology of polyamide and water resistance, which is applied in the field of fluorine-containing water-resistant polyamide 6 and its preparation, can solve the problems of dimensional stability decline, material volume expansion, and size reduction, and achieve a balance between mechanical properties, high modulus, and space The effect of high steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A preparation method of fluorine-containing water-resistant polyamide 6, the specific steps are as follows:

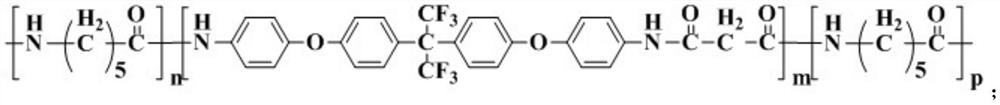

[0052] (1) 2,2-bis[4-(4-aminophenoxybenzene)]hexafluoropropane with a molar ratio of 1:1 and malonic acid in dicyclohexylcarbodiimide and 4-N,N -Under the action of lutidine, react at a temperature of 110°C for 1 hour, and then vacuum-dry at 60°C for 2 hours to obtain a fluorine-containing chain extender; wherein, malonic acid: dicyclohexylcarbodiimide: 4- The molar ratio of N,N-lutidine is 1:0.5:1;

[0053] The structural formula of the obtained fluorine-containing chain extender is: m is 43, molecular weight is 26015Da;

[0054] (2) Use caprolactam, water, phosphoric acid, and tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester as raw materials at a temperature of 220°C and a vacuum of -0.05MPa Reaction for 10 minutes, and then precondensation reaction for 1.5 hours under a pressure of 0.3 MPa to obtain a prepolymer of polyamid...

Embodiment 2

[0066] A preparation method of fluorine-containing water-resistant polyamide 6, the specific steps are as follows:

[0067] (1) 2,2'-bis(trifluoromethyl)diaminobiphenyl and succinic acid at a molar ratio of 1:1 in dicyclohexylcarbodiimide and 4-N,N-lutidine Under the action of , react at a temperature of 100°C for 1h, and then vacuum dry at 60°C for 2h to obtain a fluorine-containing chain extender; wherein,

[0068] The molar ratio of succinic acid: dicyclohexylcarbodiimide: 4-N,N-lutidine is 1:0.5:1;

[0069] The structural formula of the obtained fluorine-containing chain extender is: m is 50, molecular weight is 22050Da;

[0070] (2) Use caprolactam, water, boric acid, and 2,6-p-di-tert-butyl-p-cresol as raw materials, react for 10 minutes at a temperature of 235°C, and a vacuum of -0.05MPa, and then under the condition of a pressure of 0.3MPa Precondensation reaction 0.5h, obtains the prepolymer of polyamide 6;

[0071] Wherein, the mass ratio of caprolactam, boric a...

Embodiment 3

[0078] A preparation method of fluorine-containing water-resistant polyamide 6, the specific steps are as follows:

[0079] (1) 2,2'-bis(4-aminophenyl)hexafluoropropane and glutaric acid at a molar ratio of 1:1 in dicyclohexylcarbodiimide and 4-N,N-lutidine Under the action of , react at a temperature of 110°C for 1h, and then vacuum-dry at 60°C for 2h to obtain a fluorine-containing chain extender; wherein,

[0080] The molar ratio of glutaric acid: dicyclohexylcarbodiimide: 4-N,N-lutidine is 1:0.5:1;

[0081] The structural formula of the obtained fluorine-containing chain extender is: m is 27, molecular weight is 12582Da;

[0082] (2) Use caprolactam, water, phosphoric acid ester, and 2,6-tert-butyl-4-methylphenol as raw materials, react at a temperature of 230°C and a vacuum of -0.05MPa for 10min, and then Precondensation reaction 1h under condition, obtain the prepolymer of polyamide 6;

[0083] Wherein, the mass ratio of caprolactam, phosphoric acid ester and water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com