Anti-fog coating and preparation method thereof

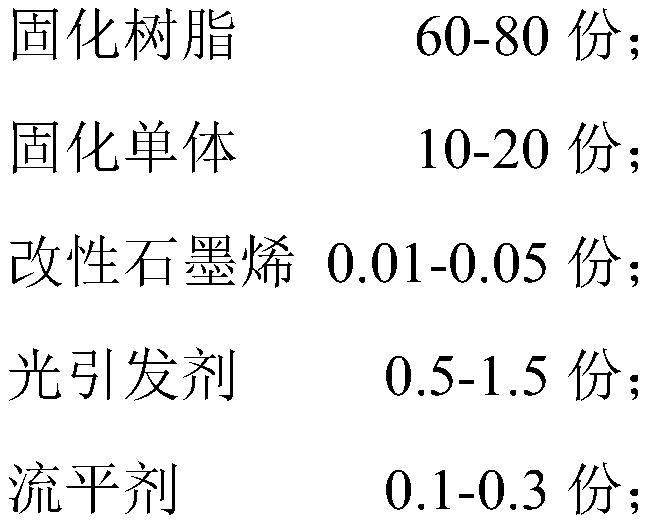

An anti-fog coating and graphene technology, applied in the field of coatings, can solve the problems of unsatisfactory perspective effect of anti-fog coatings and comprehensive effects of mechanical properties, achieve good visual perception, improve hardness and wear resistance, and prevent fog droplets. effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

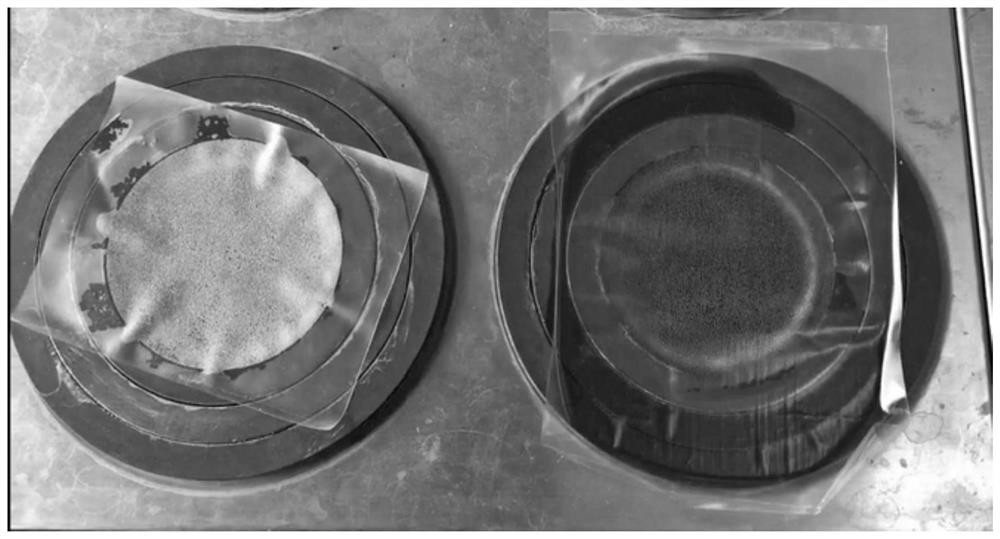

Image

Examples

preparation example Construction

[0027] The saturated fatty acid saponification solution may be a saponification solution of stearic acid, lauric acid and palmitic acid. The specific preparation method includes: saponifying saturated fatty acid and sodium hydroxide at a temperature of 70-90°C to obtain saponified liquid, wherein the amount of sodium hydroxide is 20-30% of the mass of saturated fatty acid.

[0028] Further, the mass ratio of the saturated fatty acid saponification liquid and alkylphenol polyoxyethylene ether sodium sulfate is 2-4:1; The mass ratio of betaine ester is 1-2:1; the mass ratio of the first treatment agent and the second treatment agent is 1-2:1. (The hydrophilic modification of graphene in the above-mentioned ratio range can well achieve the effect of modification and can well avoid excessive waste of material consumption.

[0029] Specifically, the preparation method of this modified graphene comprises:

[0030] T1: Add graphene SE1430 into ethylene glycol solvent, and ultrasoni...

Embodiment 1

[0050] A kind of transparent light curing graphene anti-fog coating, its raw material is as shown in table 1.

[0051] Table 1

[0052] Raw material name Dosage (%) SW-808 resin 69 Modified Graphene SE1430 0.01 BYK-333 leveling agent 0.2 TPO photoinitiator 1 DPGDA 15 Butanol 4.79 Absolute ethanol 10

[0053] The preparation method of this transparent light-cured graphene anti-fog coating comprises the steps:

[0054] S1. Weigh the SW-808 resin and put it into the reaction kettle, open the stirrer in the reaction kettle to stir;

[0055] S2. Add modified graphene SE1430 to the reaction kettle (the modification step includes: adding graphene to ethanol, stirring ultrasonically for 30min at a temperature of 60°C and a rotating speed of 300r / min to obtain graphite with a concentration of 50mg / mL Graphene suspension; Adding to graphene suspension is the first surface treatment agent that graphene weight is 5%, and describe...

Embodiment 2

[0061] A kind of transparent light curing graphene anti-fog coating, its raw material is as shown in table 2.

[0062] Table 2

[0063] Raw material name Dosage (%) SW-808 resin 69 Modified Graphene SE1430 0.02 BYK-333 leveling agent 0.2 TPO photoinitiator 1 DPGDA 15 Butanol 4.78 Absolute ethanol 10

[0064] The preparation method of this transparent light-cured graphene anti-fog coating is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com