Near-infrared fluorescent powder as well as preparation method and application thereof

A near-infrared and phosphor technology, applied in the field of near-infrared phosphors, can solve the problem that the emission spectrum cannot meet the requirements for use, and achieve the effects of being convenient for large-scale production and popularization and application, mature in structure, and short in preparation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The application provides a preparation method of near-infrared fluorescent powder, comprising the following steps:

[0047] mixing a compound containing La, a compound containing M, a compound containing Sc, a compound containing B and a compound containing Cr to obtain a mixture;

[0048] The mixture is sintered to obtain near-infrared fluorescent powder.

[0049] According to the above-mentioned method provided by the present invention, the preparation method of the near-infrared fluorescent powder of the present application is simple in process, low in cost, and easy to industrialized production.

[0050] According to the element composition of the obtained near-infrared fluorescent powder, the molar ratio of the compound containing La, the compound containing M, the compound containing Sc, the compound containing B and the compound containing Cr is (0.64~0.83): (0.24~ 0.648): (2.71-2.88): (4.00-4.10): (0.002-0.05).

[0051] For the selection of the above compounds...

Embodiment 1

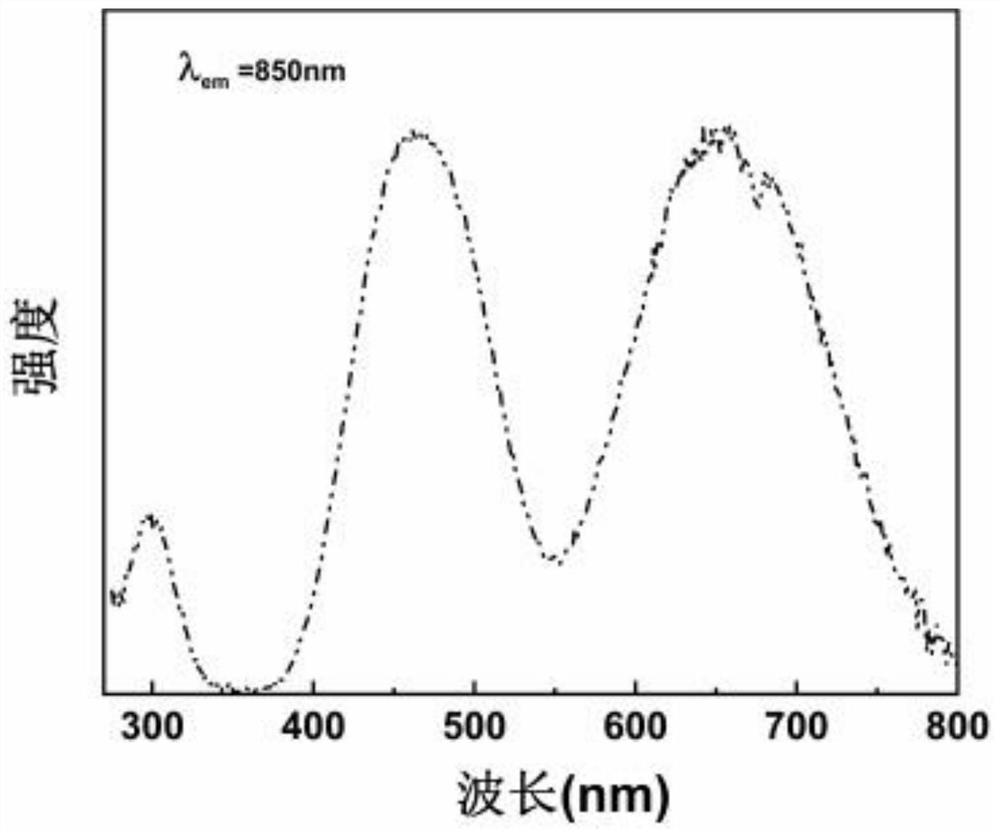

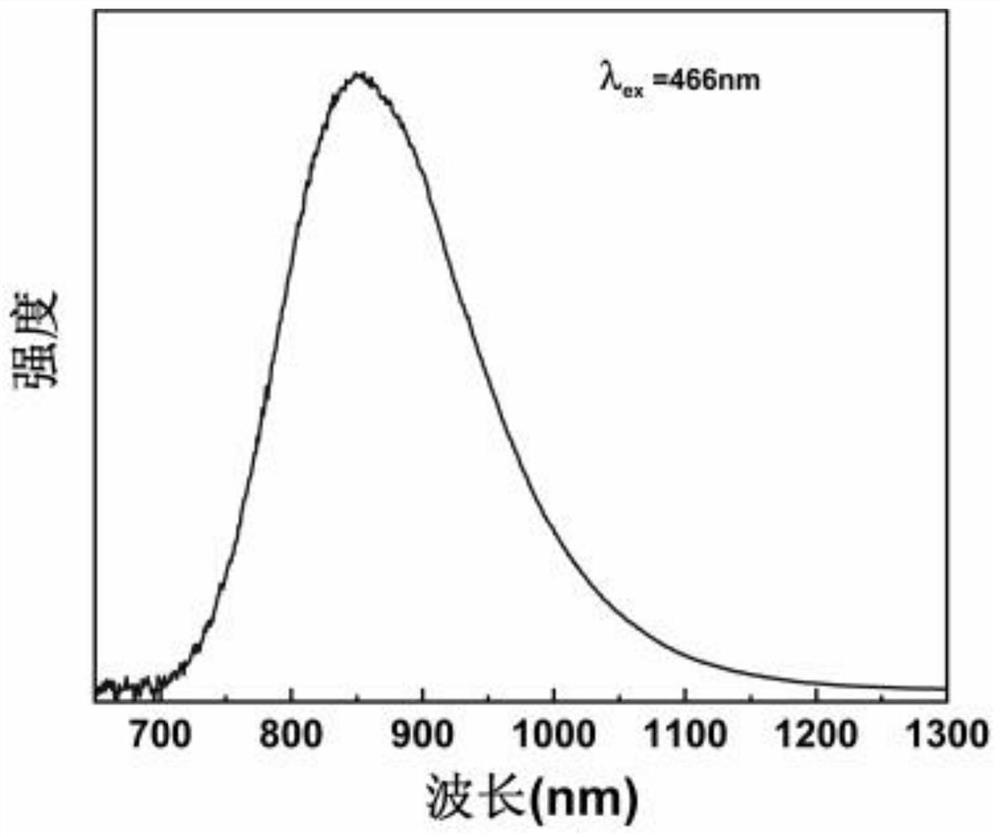

[0064] La 2 o 3 (analytical pure), Y 2 o 3 (analytical pure), Sc 2 o 3 (analytical pure), H 3 BO 3 (analytical pure) and Cr 2 o 3 (99.99%) as raw materials, according to the molar ratio of 0.64:0.648:2.71:8:0.002, accurately weigh the above substances, and fully grind them evenly in an agate mortar, put them into a corundum crucible, and place them in a box furnace in an air atmosphere Roast at 1150°C for 10 hours, cool naturally to room temperature, and then grind to obtain a light green powder sample whose chemical composition is La 0.64 Y 0.648 sc 2.71 (BO 3 ) 4:0.002Cr 3+ . After testing, La 0.64 Y 0.648 sc 2.71 (BO 3 ) 4 :0.002Cr 3+ Its chemical properties are stable, non-radioactive, and will not cause harm to the environment; its excitation band is wide and can be effectively excited by light in the 250-650nm band; its emission spectrum has a broad peak of 650nm-1200nm, and the main emission peak is located near 850nm.

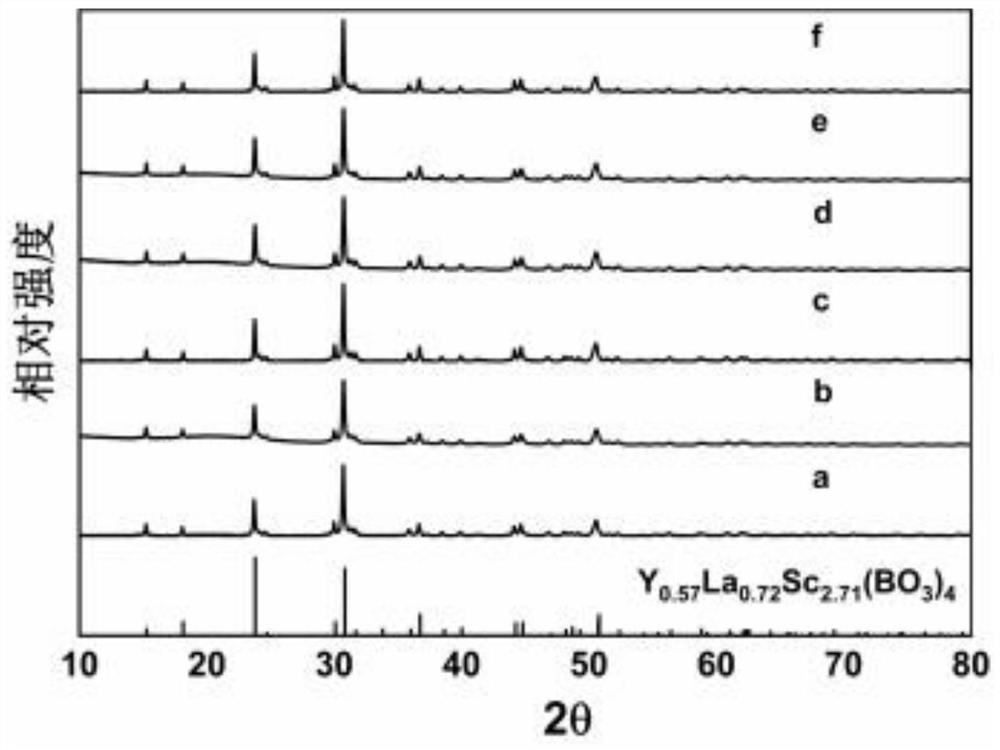

[0065] Carry out X-ray diffr...

Embodiment 2

[0067] La 2 o 3 (analytical pure), Gd 2 o 3 (analytical pure), Sc 2 o 3 (analytical pure), H 3 BO 3 (analytical pure) and Cr 2 o 3 (99.99%) as a raw material, according to the molar ratio of 0.64:0.43:2.88:8:0.05, accurately weigh the above substances, and fully grind them evenly in an agate mortar, put them into a corundum crucible, and place them in a box furnace in air Calcined at 1150°C for 10 hours in the atmosphere, cooled naturally to room temperature, and then ground to obtain a light green powder sample whose chemical composition is La 0.64 Gd 0.43 sc 2.88 (BO 3 ) 4 :0.05Cr 3+ . After testing, La 0.64 Gd 0.43 sc 2.88 (BO 3 ) 4 :0.05Cr 3+ Its chemical properties are stable, non-radioactive, and will not cause harm to the environment; its excitation band is wide and can be effectively excited by light in the 250-650nm band; its emission spectrum has a broad peak of 650nm-1200nm, and the main emission peak is located near 850nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com