Optical fiber structure for temperature detection, manufacturing method and temperature detection system

A technology of optical fiber structure and manufacturing method, which is applied in the field of detection, can solve the problems of limited application environment and application prospects, large influence of thermistor temperature, weak anti-interference ability, etc., achieve good application prospects and development value, and improve evanescent field , the effect of solid structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

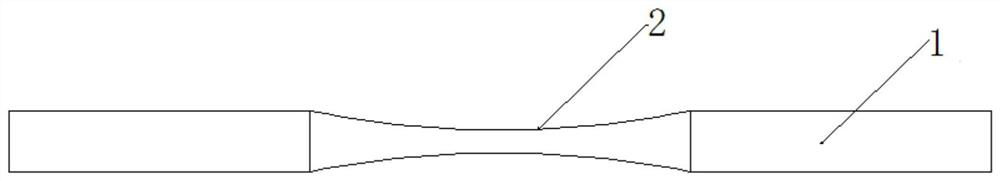

[0030] like figure 1 As shown, the embodiment of the present disclosure provides an optical fiber structure for temperature detection, mainly including two single-mode optical fibers 1 and a coreless optical fiber 2 arranged between the two single-mode optical fibers, wherein the coreless optical fiber 2 and the Two single-mode optical fibers 1 are placed coaxially, and the two ends of the coreless optical fiber 2 in the length direction are respectively fixed together with the two single-mode optical fibers.

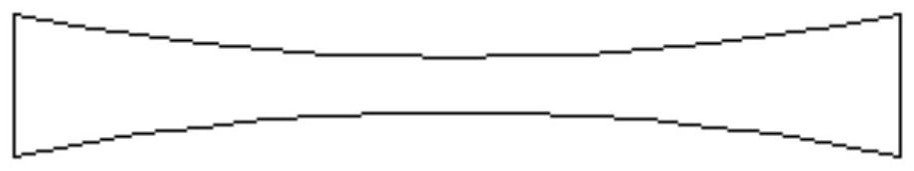

[0031] like figure 2 As shown, the coreless fiber is tapered into a structure with a thin center and thick ends. Preferably, the diameter of the middle part of the coreless fiber is equal to the radius of a single single-mode fiber, which is convenient for practical fiber welding.

[0032] In this embodiment, the two ends of the coreless fiber in the length direction are welded together with the ends of the single-mode fiber respectively.

[0033] Further, a capillar...

Embodiment 2

[0038] The following describes in detail the method for manufacturing the above-mentioned optical fiber structure for temperature detection, the method includes the following process:

[0039] Step 1: Splice the two ends of the untapered coreless fiber with the end of the single-mode fiber respectively to form a cascaded structure through the fusion splicing equipment, and then put the coreless fiber forming the cascaded structure on the fusion splice On the equipment, the two ends of the wireless optical fiber or the end of the single-mode fiber are respectively clamped by the two clamping pieces of the fusion splicing equipment, and the stepper motor connected to the clamping pieces is controlled by the controller in the fusion splicing equipment to move along the coreless fiber The axis line pulls the fiber slowly at a constant speed, and finally forms a structure with a thin middle and thick ends.

[0040] In the second step, a capillary quartz tube is set on the outer wal...

Embodiment 3

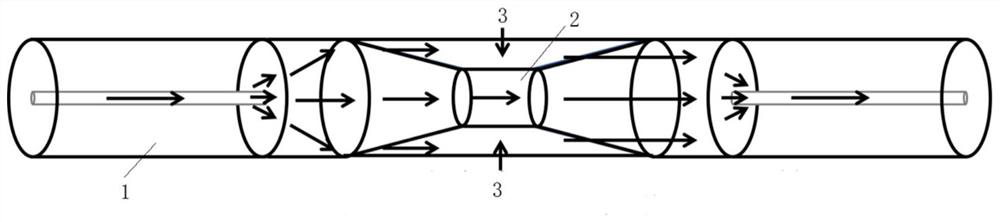

[0044] The following describes in detail the temperature detection system or device comprising the above-mentioned optical fiber structure, such as Figure 4 As shown, the detection device mainly includes ASE (broadband light source) equipment 4 , the optical fiber structure 5 , wide and narrow optical filters 6 , PIN tube 7 , amplifier circuit 8 , acquisition card 9 and computer 10 .

[0045]One end in the length direction of the optical fiber structure 5 is connected to the ASE device (broadband light source) 4, and the other end is connected to a suitable central wavelength (such as Image 6 The narrow-band optical filter 6 of 1577nm shown in the vertical line in the) is sent to PIN tube 7. exist Image 6 Among them, the light intensity at 1577nm changes with the change of temperature (the movement of the interference spectrum). As the temperature increases, the light intensity gradually increases, and each temperature corresponds to a specific light intensity. The PIN tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com