IGBT chip and preparation method thereof

A technology of chip and conductive type, applied in the field of IGBT chip and its preparation, can solve the problems of large error, achieve the effect of low additional cost, improve performance and reliability, and expand the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

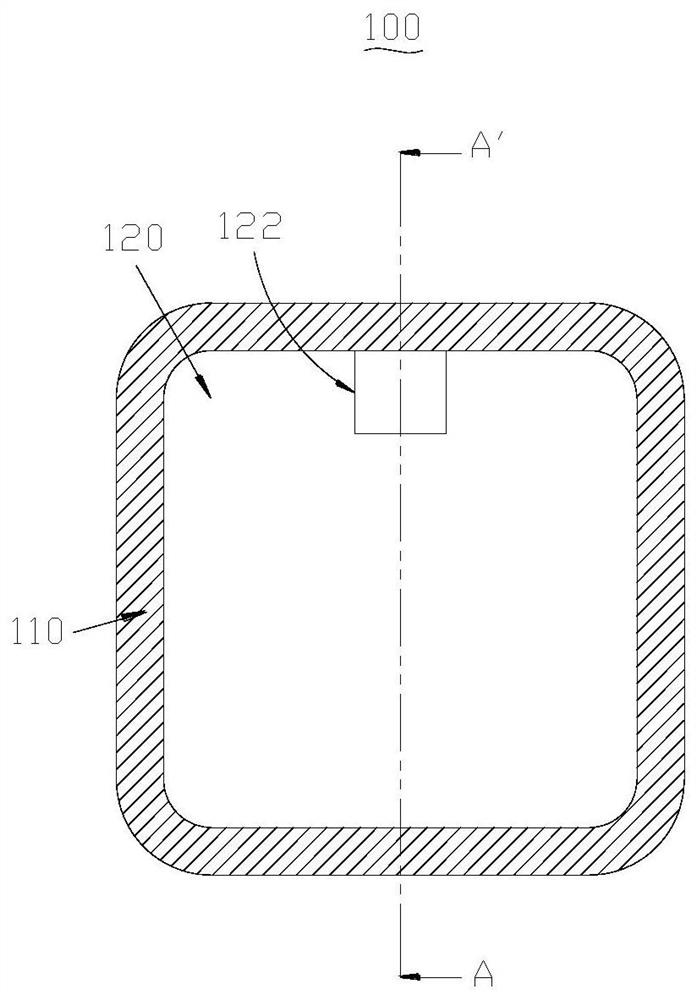

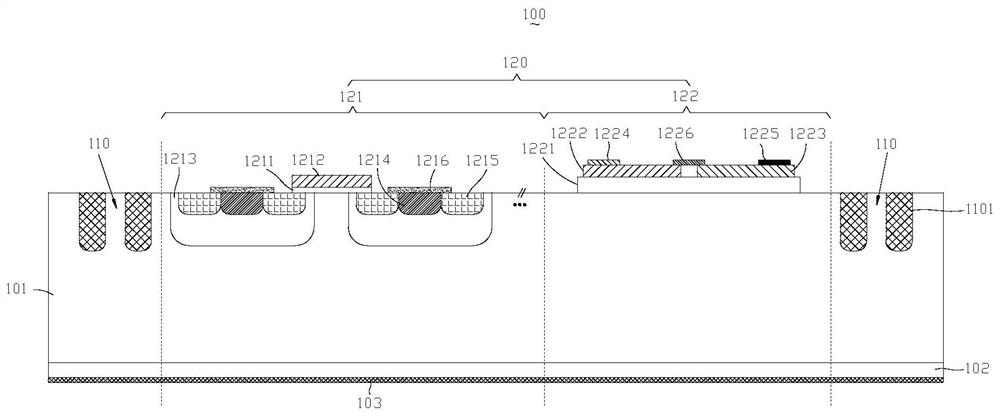

[0060] Such as figure 1 As shown, an IGBT chip 100 with a planar gate structure includes a terminal protection region 110 and a cell region 120 . The cell area 120 is located in the middle of the IGBT chip 100 , and the terminal protection area 110 is located at the edge of the IGBT chip 100 and surrounds the cell area 120 .

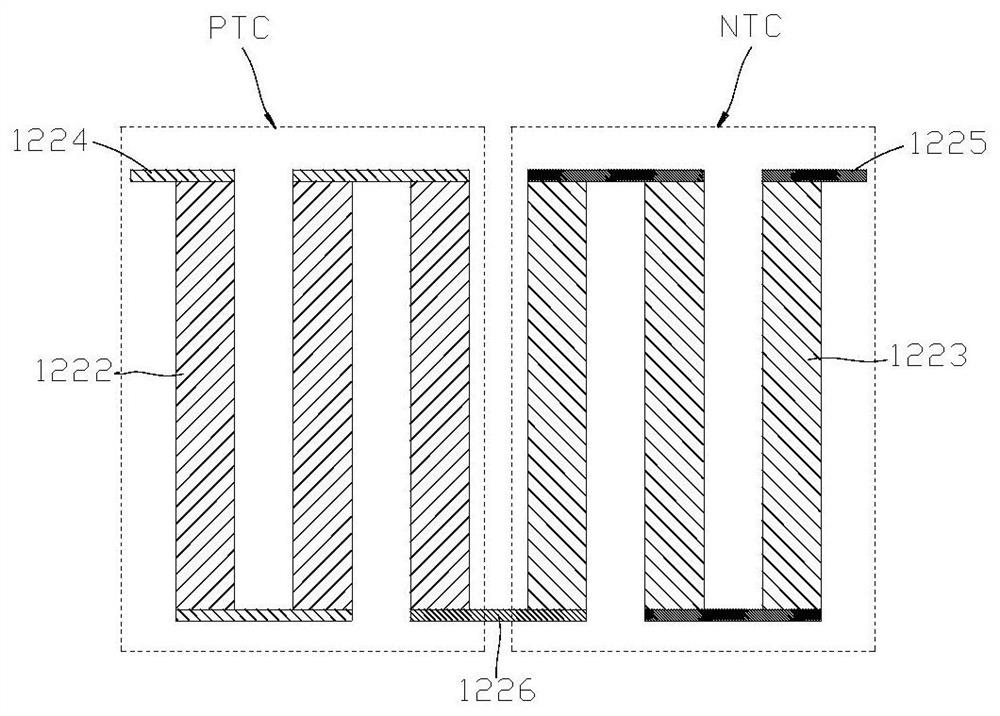

[0061] The cell area 120 includes an IGBT cell area 121 and a temperature sensing area 122 . The temperature sensing area 122 can be located at any position of the cellular area 120 , and in this embodiment, the temperature sensing area 122 is located at the edge of the cellular area 120 as an example.

[0062] Such as figure 2 As shown, both the terminal protection region 110 and the cell region 120 include the substrate 101 of the IGBT chip, the collector layer 102 and the collector metal layer 103 .

[0063] Exemplarily, the substrate 101 is a substrate of the first conductivity type. The collector layer 102 is a collector layer of the second con...

Embodiment 2

[0103] Such as Figure 6 , an IGBT chip 200 with a planar gate structure, including a terminal protection region 210 and a cell region 220 . The cell area 220 includes an IGBT cell area 221 and a temperature sensing area 222 . The temperature sensing area 222 can be located at any position of the cellular area 220 , and in this embodiment, the temperature sensing area 222 is located at the edge of the cellular area 220 as an example.

[0104] Both the terminal protection area 210 and the cell area 220 include the substrate 201 of the IGBT chip, the collector layer 202 and the collector metal layer 203 .

[0105] Exemplarily, the substrate 201 is a substrate of the first conductivity type. The collector layer 202 is a collector layer of the second conductivity type and is located below the substrate 201 . The collector metal layer 203 is located under the collector layer 202 and forms an ohmic contact with the collector layer 202 .

[0106] The terminal protection area 210 ...

Embodiment 3

[0145] Such as Figure 9 As shown, on the basis of the first embodiment, this embodiment provides an IGBT chip 300 with a trench gate structure, which includes a terminal protection region 310 and a cell region 320 . The cell area 320 is located in the middle of the IGBT chip 300 , and the terminal protection area 310 is located at the edge of the IGBT chip 300 and surrounds the cell area 320 .

[0146] The cell area 320 includes an IGBT cell area 321 and a temperature sensing area 322 . The temperature sensing region 322 can be located at any position of the cellular region 320 , and in this embodiment, the temperature sensing region 322 is located at the edge of the cellular region 320 as an example.

[0147] Both the terminal protection area 310 and the cell area 320 include the substrate 101 of the IGBT chip, the collector layer 302 and the collector metal layer 303 .

[0148] Exemplarily, the substrate 101 is a substrate of the first conductivity type. The collector la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com