Palladium activation method for electro-less nickel immersion gold of PCB (printed circuit board)

A PCB circuit board and chemical nickel-gold technology, which is applied in the field of palladium activation of chemical nickel-gold on PCB circuit boards, can solve the problems of surface roughness, increase bonding ability, etc., achieve excellent soldering performance, eliminate false soldering, and be easy to process and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

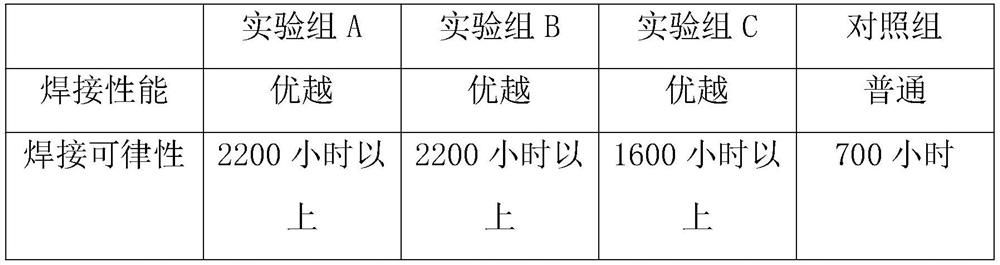

Examples

Embodiment 1

[0046] Step 1: Place the product in an acidic cleaner for degreasing cleaning;

[0047] Step 2: pickling with pickling solution, the pickling solution contains substances with a concentration of 5% retarder, remove surface oxides, use pickling solution to wash and remove acid again, after hydrogen displacement treatment, heat and dry at 200°C Bake for 4 hours, wash with water and put into the electroless palladium plating tank, and electroless palladium plating for 10 minutes;

[0048] Step 3: Put the product in hot water at 50°C for cleaning, then put it in ionized water for 1-3 minutes, and drain the cleaning water;

[0049] Step 4: Microetching the product to form a microstructure;

[0050] Step 5: put in ionized water and circulate for 1 minute, then drain the cleaning water;

[0051] Step 6: After putting the product into the phosphoric acid solution for 0.5 min, transfer it to an activation tank with a palladium activator, treat it at 25°C for 1 min, and deposit activa...

Embodiment 2

[0056] Step is the same as embodiment 1;

[0057] Step 2: pickling with pickling solution, the pickling solution contains substances with a concentration of 6% retarder, remove surface oxides, use pickling solution to wash and remove acid again, after hydrogen displacement treatment, heat and dry at 190°C Bake for 3.5 hours, wash with water and put into the electroless palladium plating tank, electroless palladium plating for 8 minutes;

[0058] Step 3: Put the product in hot water at 60°C for cleaning, then put it in ionized water for 1-3 minutes, and drain the cleaning water;

[0059] Step 4 is the same as embodiment 1;

[0060] Step 5: put in ionized water and circulate for 3 minutes, and drain the cleaning water;

[0061] Step 6: After putting the product into the phosphoric acid solution for 1 min, transfer it to an activation tank with a palladium activator, treat it at 30°C for 3 min, and deposit activated palladium on the surface of the product;

[0062] Step 7: Put...

Embodiment 3

[0066] Step is the same as embodiment 1;

[0067] Step 2: pickling with pickling solution, the pickling solution contains substances with a concentration of 4% retarder, remove surface oxides, use pickling solution to wash and remove acid again, after hydrogen displacement treatment, heat and dry at 180°C Bake for 3 hours, wash with water and put into the electroless palladium plating tank, and electroless palladium plating for 5 minutes;

[0068] Step 3: Put the product in hot water at 55°C for cleaning, then put it in ionized water for 1-3 minutes, and drain the cleaning water;

[0069] Step 4 is the same as embodiment 1;

[0070] Step 5: put in ionized water and circulate for 2 minutes, and drain the cleaning water;

[0071] Step 6: After putting the product into the phosphoric acid solution for 0.8 minutes, transfer it to an activation tank with a palladium activator, treat it at 28°C for 2 minutes, and deposit activated palladium on the surface of the product;

[0072]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com