An artificial thylakoid microfluidic chip and its preparation method and application

A microfluidic chip and thylakoid technology, applied in the field of biochemistry, can solve the problems of poor compatibility between photocatalytic materials and biocatalytic enzymes, low utilization rate of oxidoreductase, complicated recovery steps, etc. The effect of reaction efficiency, high utilization rate and easy recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

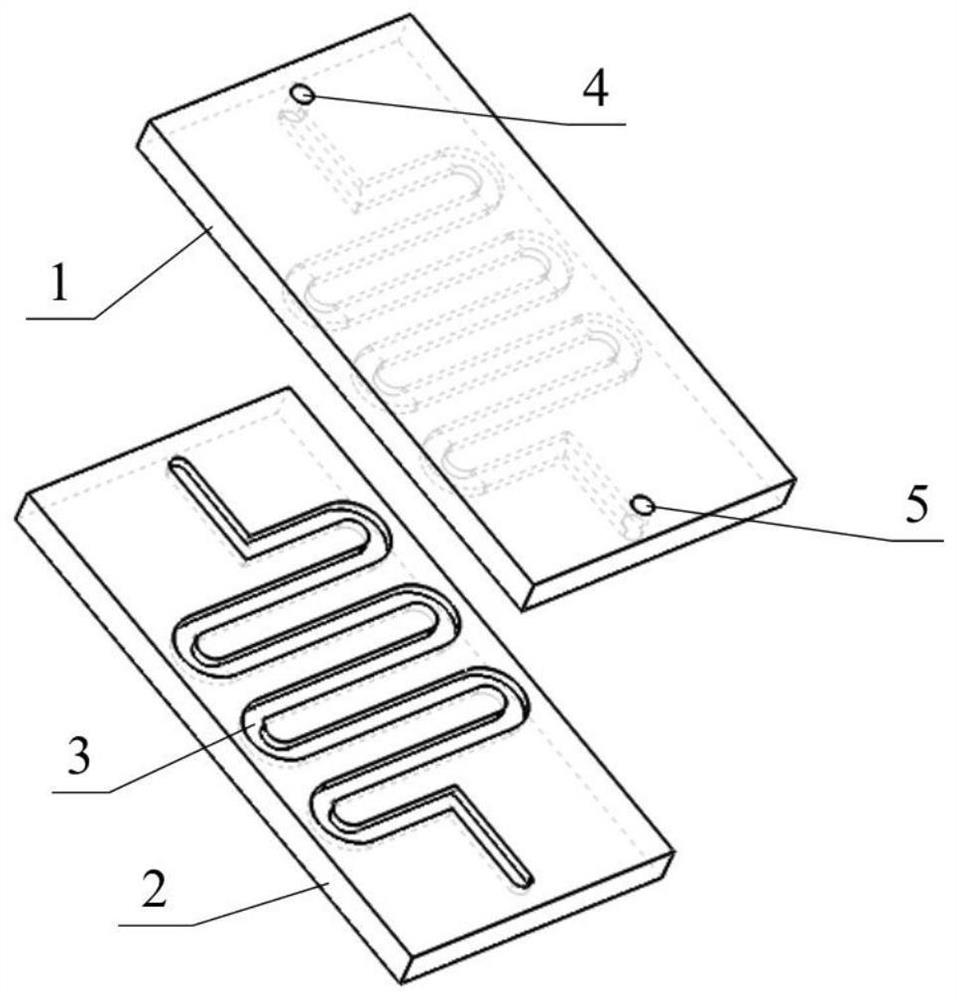

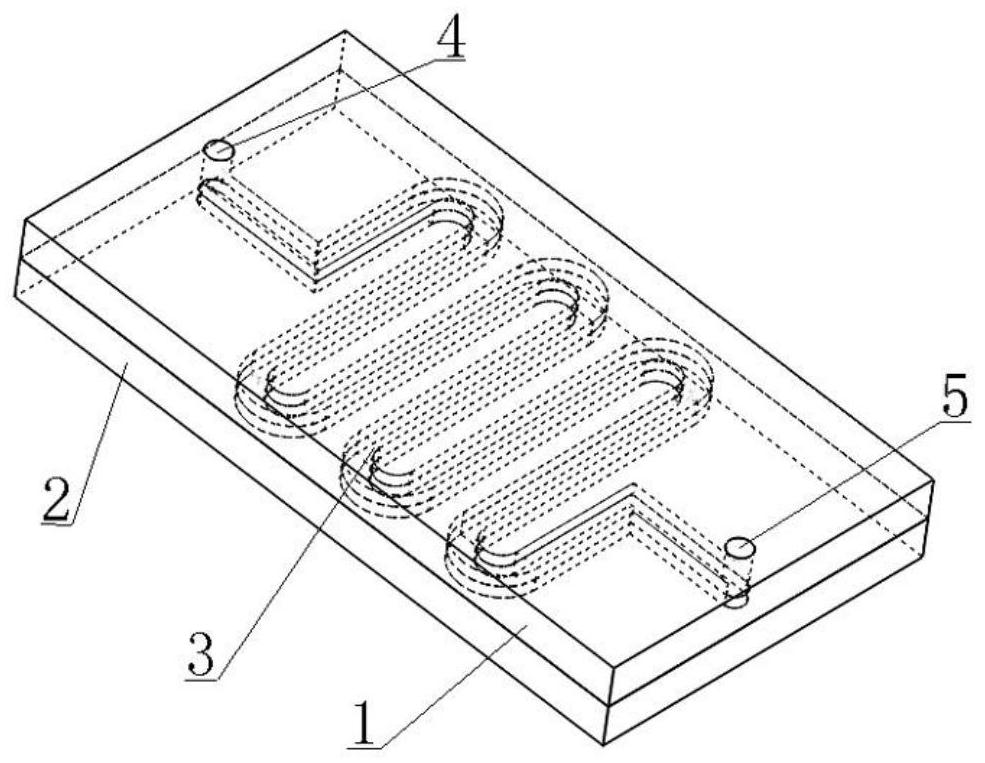

[0038] The artificial thylakoid microfluidic chip is composed of two microfluidic chip channels bonded up and down to form a cavity 3 composed of an upper structure 1 and a lower structure 2, and the inner surface of the cavity 3 upper structure 1 Coated with mpg-C 3 N 4 The inner surface of the lower structure 2 of the cavity 3 is firstly added with 3-aminopropyltriethoxysilane, then dopamine is added for chemical modification, and then the inner surface of the lower structure 2 of the cavity 3 is injected with a concentration of 1mg / ml of glutamate dehydrogenase solution.

[0039] Two ends of the cavity 3 are provided with a sample inlet 4 and a sample outlet 5 .

[0040] The preparation method of the artificial thylakoid microfluidic chip comprises the following steps:

[0041] (1) Prepare the PDMS prepolymer and the curing agent according to the mass ratio of 10:1, stir evenly, remove the air bubbles with a vacuum pump, and prepare the mixed PDMS mixture;

[0042] (2)...

Embodiment 2

[0048] The artificial thylakoid microfluidic chip is composed of two microfluidic chip channels bonded up and down to form a cavity 3 composed of an upper structure 1 and a lower structure 2, and the inner surface of the cavity 3 upper structure 1 Coated with 2D COF, the inner surface of the lower structure 2 of the cavity 3 is firstly added with 3-aminopropyltriethoxysilane, and then dopamine is added for chemical modification, and then the inner surface of the lower structure 2 of the cavity 3 A solution of glutamate dehydrogenase at a concentration of 8 mg / ml was injected into the surface.

[0049] Two ends of the cavity 3 are provided with a sample inlet 4 and a sample outlet 5 .

[0050] The preparation method of the artificial thylakoid microfluidic chip comprises the following steps:

[0051] (1) Prepare the PDMS prepolymer and the curing agent according to the mass ratio of 10:1, stir evenly, remove the air bubbles with a vacuum pump, and prepare the mixed PDMS mixtur...

Embodiment 3

[0058] The artificial thylakoid microfluidic chip is composed of two microfluidic chip channels bonded up and down to form a cavity 3 composed of an upper structure 1 and a lower structure 2, and the inner surface of the cavity 3 upper structure 1 coated with g-C 3 N 4 Quantum dots, first add 3-aminopropyltriethoxysilane to the inner surface of the lower structure 2 of the cavity 3, then add dopamine for chemical modification, and then inject a concentration of 15mg / ml glutamate dehydrogenase solution.

[0059] Two ends of the cavity 3 are provided with a sample inlet 4 and a sample outlet 5 .

[0060] The preparation method of the artificial thylakoid microfluidic chip comprises the following steps:

[0061] (1) Prepare the PDMS prepolymer and the curing agent according to the mass ratio of 10:1, stir evenly, remove the air bubbles with a vacuum pump, and prepare the mixed PDMS mixture;

[0062] (2) The SU-8 mold is made by soft etching technology, and two identical micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com