Method for preparing potassium fluoride by using potassium alkali and potassium fluosilicate

A technology of potassium fluorosilicate and using potash, applied in the field of chemical and chemical fine chemicals, can solve the problems of low utilization rate of equipment, small scale of a single set of equipment, and no construction of industrialized devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

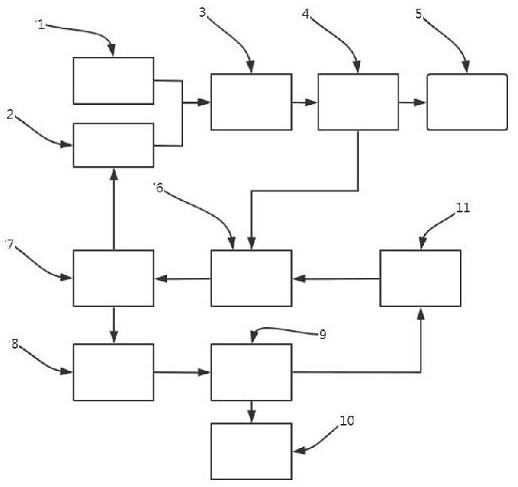

Image

Examples

Embodiment 1

[0022] 200kg of 48% potash and 150kg of potassium fluorosilicate are mixed in the reaction tank. After the complete reaction and precipitation, the silicon dioxide is filtered with a plate filter, the mother liquor is concentrated and crystallized, and the solid is separated by a plate filter. The solid is potassium fluoride. The mother liquor returns to the reaction tank and fluorine participates in the reaction. The solid potassium fluoride was dried by spray drying at 550 degrees Celsius to obtain 98.5% anhydrous potassium fluoride. The waste heat tail gas is returned to concentrate and crystallize the mother liquor.

Embodiment 2

[0024] 200kg of 48% potash and 150kg of potassium fluorosilicate are mixed in the reaction tank. After the complete reaction and precipitation, the silicon dioxide is filtered with a plate filter, the mother liquor is concentrated and crystallized, and the solid is separated by a plate filter. The solid is potassium fluoride. The mother liquor returns to the reaction tank and fluorine participates in the reaction. The solid potassium fluoride was dried by spray drying at 600 degrees Celsius to obtain 98.7% anhydrous potassium fluoride. The waste heat tail gas is returned to concentrate and crystallize the mother liquor.

Embodiment 3

[0026] 200kg of 48% potash and 150kg of potassium fluorosilicate are mixed in the reaction tank. After the complete reaction and precipitation, the silicon dioxide is filtered with a plate filter, the mother liquor is concentrated and crystallized, and the solid is separated by a plate filter. The solid is potassium fluoride. The mother liquor returns to the reaction tank and fluorine participates in the reaction. The solid potassium fluoride was dried by spray drying at 500 degrees Celsius to obtain 98.6% anhydrous potassium fluoride. The waste heat tail gas is returned to concentrate and crystallize the mother liquor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com