Preparation method of heterojunction CoO/CoS porous nanorod, obtained material and application

A nanorod and heterojunction technology, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of poor conductivity and low OER overpotential of transition metal oxides, and achieve improved Electrocatalytic oxidation performance, performance enhancement, and the effect of enriching mass transfer channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing heterojunction CoO / CoS porous nanorods, comprising the following steps:

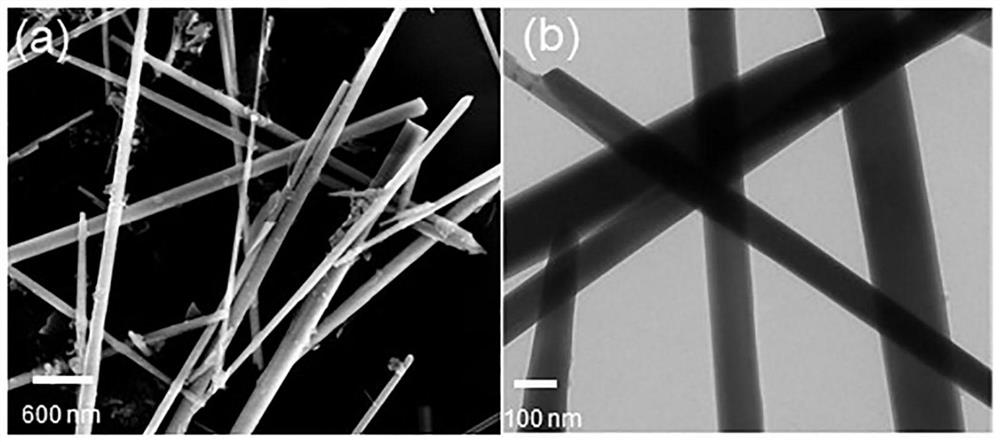

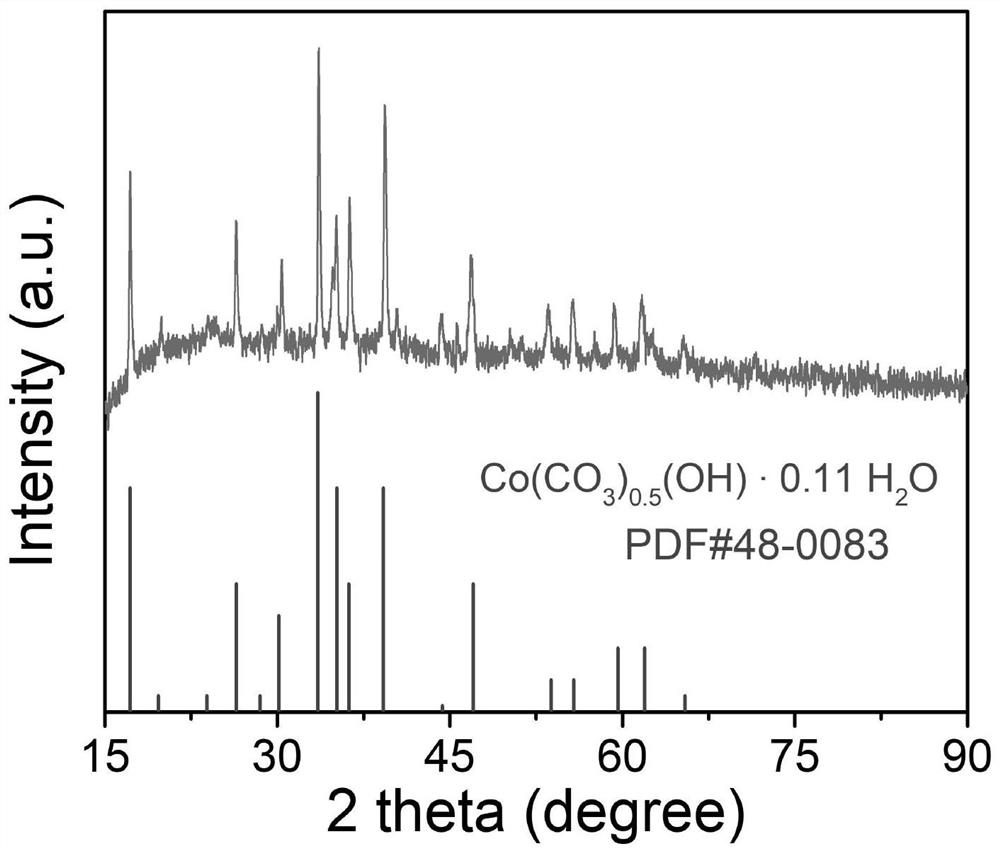

[0034] 1) Synthesis of Co-citrulline nanorod precursor: 2mmol L-citrulline and 1mmol Co(NO 3 ) 2 Dissolved in 35mL distilled water to form a pink clear solution, transferred to a 50mL autoclave, and reacted at 160°C for 5h. Subsequently, the water-alcohol mixed solution was centrifuged and washed several times, and after vacuum drying, a light pink powder was obtained, which was the Co-citrulline nanorod precursor;

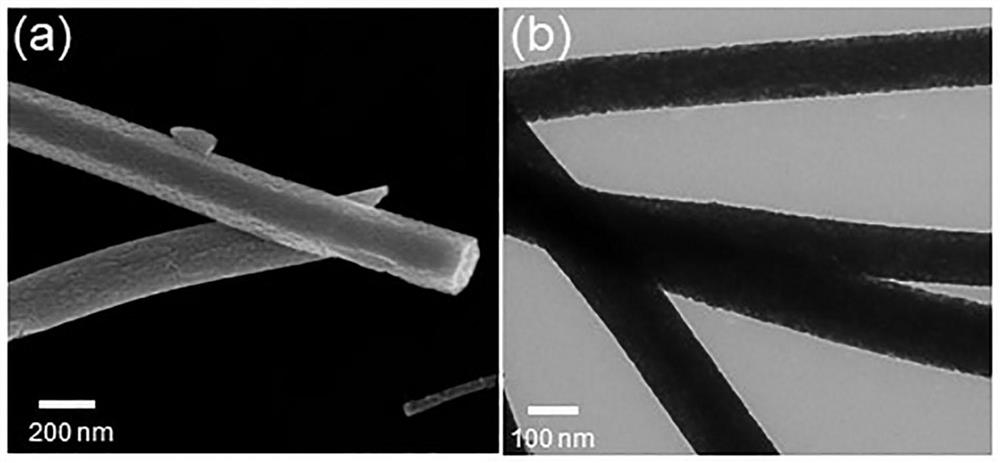

[0035] 2) Preparation of heterojunction CoO / CoS porous nanorods: the light pink powder prepared in step 1) was oxidized and heat-treated at a rate of 0.5 °C / min to 350 °C in an air atmosphere, and kept at this temperature for 1 h. get black co 3 o 4 porous nanorods.

[0036] 3) the black Co obtained in step 2) 3 o 4 Porous nanorods and thiourea (mass is Co 3 o 4 10 times) placed at both ends of the porcelain boat 3cm apart, in N 2 Under the atmosphere,...

Embodiment 2

[0038] A method for preparing heterojunction CoO / CoS porous nanorods, comprising the following steps:

[0039]1) Synthesis of Co-citrulline nanorod precursor: 0.1mmol L-citrulline and 1mmol Co(NO 3 ) 2 Dissolved in 35mL distilled water to form a pink clear solution, transferred to a 50mL autoclave, and reacted at 160°C for 5h. Subsequently, the water-alcohol mixed solution was centrifuged and washed several times, and after vacuum drying, a light pink powder was obtained, which was the Co-citrulline nanorod precursor;

[0040] 2) Preparation of heterojunction CoO / CoS porous nanorods: the light pink powder prepared in step 1) was oxidized and heat-treated at a rate of 0.5 °C / min to 350 °C in an air atmosphere, and kept at this temperature for 1 h. get black co 3 o 4 porous nanorods.

[0041] 3) the black Co obtained in step 2) 3 o 4 Porous nanorods and thiourea (mass is Co 3 o 4 10 times) placed at both ends of the porcelain boat 3cm apart, in N 2 Under the atmosphere...

Embodiment 3

[0043] A method for preparing heterojunction CoO / CoS porous nanorods, comprising the following steps:

[0044] 1) Synthesis of Co-citrulline nanorod precursor: 10mmol L-citrulline and 1mmol Co(NO 3 ) 2 Dissolved in 35mL distilled water to form a pink clear solution, transferred to a 50mL autoclave, and reacted at 160°C for 5h. Subsequently, the water-alcohol mixed solution was centrifuged and washed several times, and after vacuum drying, a light pink powder was obtained, which was the Co-citrulline nanorod precursor;

[0045] 2) Preparation of heterojunction CoO / CoS porous nanorods: the light pink powder prepared in step 1) was oxidized and heat-treated at a rate of 0.5 °C / min to 350 °C in an air atmosphere, and kept at this temperature for 1 h. get black co 3 o 4 porous nanorods.

[0046] 3) the black Co obtained in step 2) 3 o 4 Porous nanorods and thiourea (mass is Co 3 o 4 15 times) placed at both ends of the porcelain boat 3cm apart, in N 2 Under the atmosphere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com