Preparation method of guar gum nanofiber

A technology of nanofibers and guar gum, which is applied in the field of preparation of guar gum nanofibers, can solve the problems of unsatisfactory chain entanglement, poor spinnability of guar gum, and low spinning efficiency, and achieve optimal chain entanglement degree, low price, and the effect of improving spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

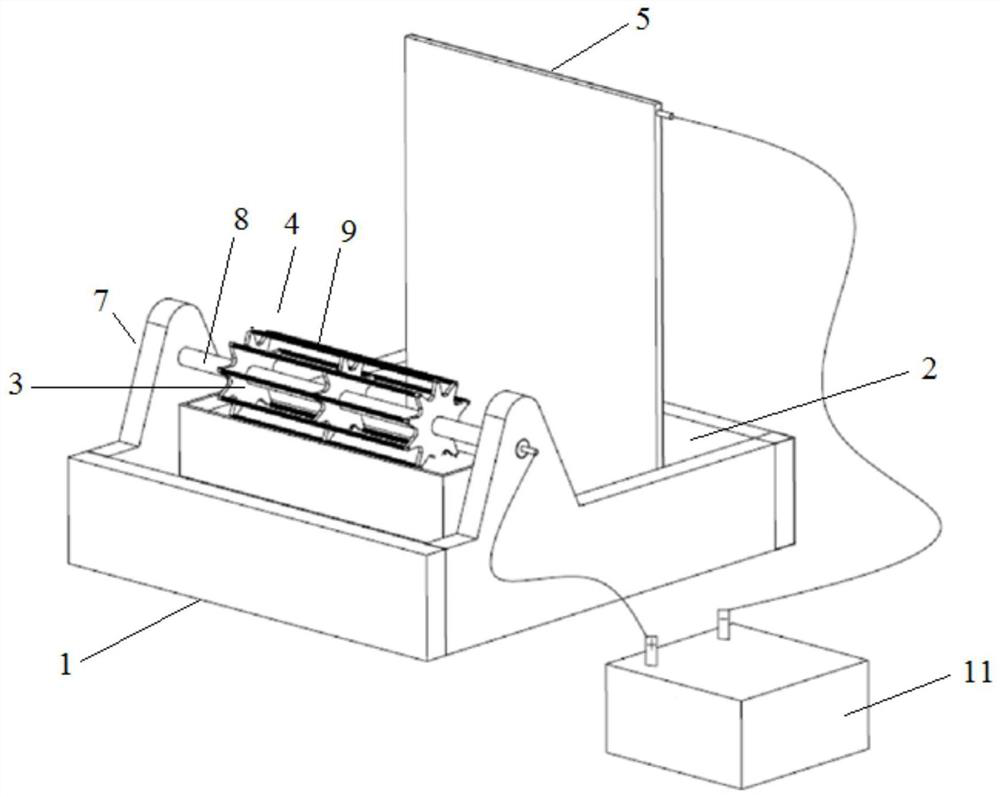

[0051] Mix dodecyldimethylbenzyl ammonium chloride cationic surfactant, guar gum and water in a weight ratio of 0.5:1.5:98, and let the guar gum swell at room temperature for 20 minutes; at room temperature and 300rpm , continue stirring for 8 hours to obtain solution A; use a high-speed centrifuge to degas solution A at 7000r / min for 30 minutes until the bubbles completely disappear, and obtain spinning stock solution B. The spinning dope B is spun and shaped by needle-based electrospinning or needle-free electrospinning to obtain guar gum nanofibers.

[0052] The spinning conditions of needle electrospinning are: static voltage 23.4kv, flow rate 1ml / h, receiving distance 15cm, temperature 35°C, humidity 10%.

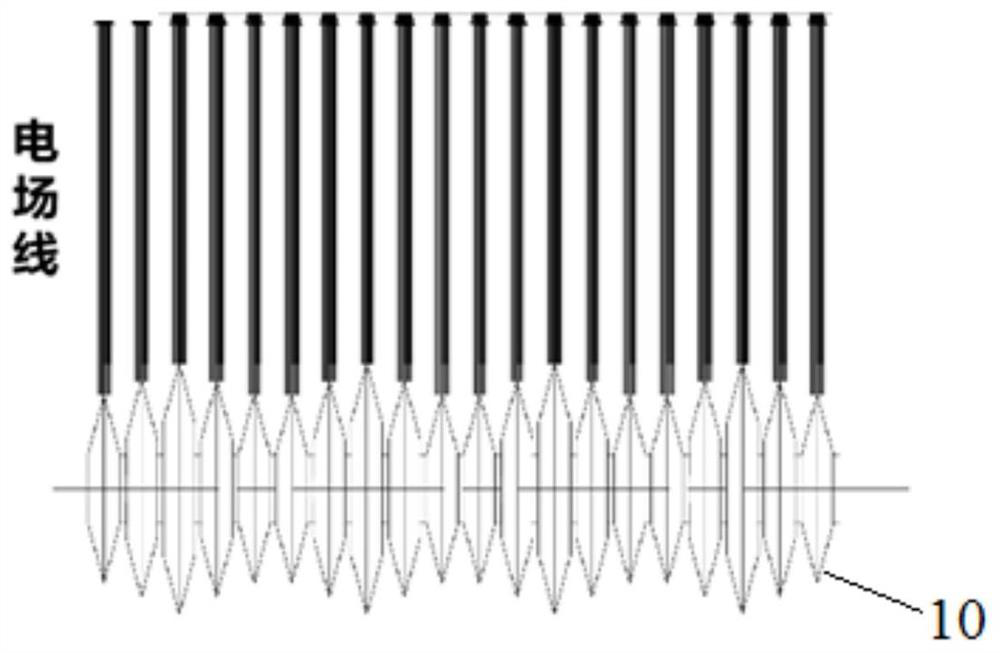

[0053] The spinning conditions of the needle-free electrospinning are as follows: static voltage 30kv, rotation speed of the multi-pinion rod outlet 30r / min, receiving distance 15cm, temperature 35°C, humidity 20%.

[0054] figure 2 and image 3 The SEM images of g...

Embodiment 2

[0056] Mix hexadecyldimethylethylammonium bromide cationic surfactant, guar gum and water at a mass ratio of 0.3:2:97.7, and the swelling time is 20 minutes; keep stirring for 8 hours at room temperature and 300 rpm , to obtain solution A; use a high-speed centrifuge to degas solution A at 7000r / min for 30 minutes until the bubbles completely disappear, and obtain spinning stock solution B. The spinning dope B is spun and formed by needle spinning or needle-free electrospinning to obtain a guar gum nanofiber membrane.

[0057] 1) The process conditions of needle electrospinning are: electrostatic voltage 23.67kv, flow rate 2ml / h, receiving distance 15cm, temperature 35°C, humidity 10%.

[0058] 2) The process conditions of needle-free electrospinning are as follows: electrostatic voltage 30kv, rotation speed of the multi-rever wire outlet 30r / min, receiving distance 15cm, temperature 35°C, humidity 20%.

[0059] Figure 4 and Figure 5 The SEM images of guar gum nanofibers ...

Embodiment 3

[0061] Mix octadecyldimethylbenzyl ammonium chloride cationic surfactant, guar gum and water at a mass ratio of 0.5:1.5:98, and the swelling time is 20 minutes; at room temperature and 300 rpm, keep stirring for 8 hours , to obtain solution A; use a high-speed centrifuge to degas solution A at 7000r / min for 30 minutes until the bubbles completely disappear, and obtain spinning stock solution B. The spinning dope B is spun and formed by needle spinning or needle-free electrospinning to obtain a guar gum nanofiber membrane.

[0062] 1) The process conditions of electrospinning with needles are: static voltage 26.85kv, flow rate 2ml / h, receiving distance 15cm, temperature 35°C, humidity 10%.

[0063] 2) The process conditions of needle-free electrospinning are as follows: electrostatic voltage 30kv, rotation speed of the multi-rever wire outlet 30r / min, receiving distance 15cm, temperature 35°C, humidity 20%.

[0064] Figure 6 and Figure 7 The SEM images of guar gum nanofibe...

PUM

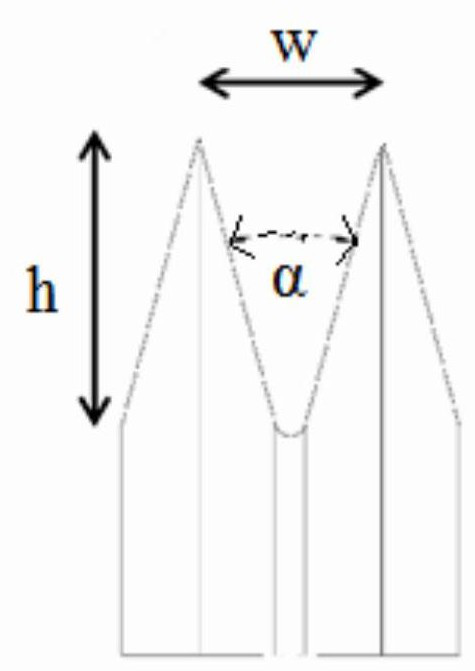

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com