Production technology of ultrasonic-assisted continuous countercurrent extraction of sapindus-saponin

A technology of sapindus saponin and countercurrent extraction, which is applied to the preparation of sugar derivatives, sugar derivatives, and sugar derivatives, etc., can solve the problems of complex process operation, long time consumption, and high product cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

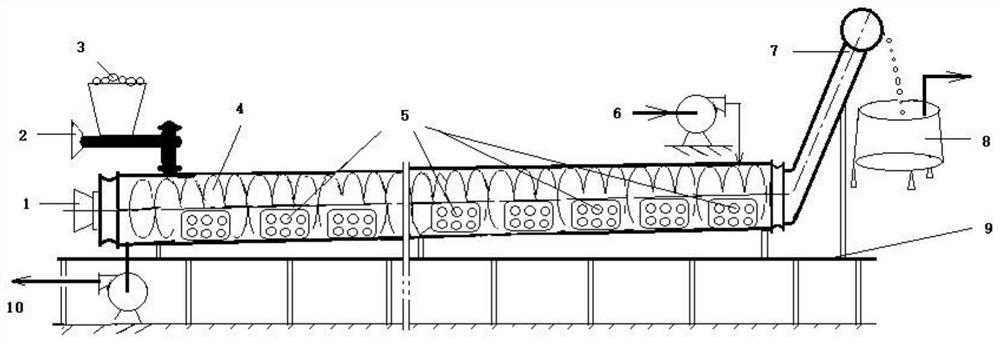

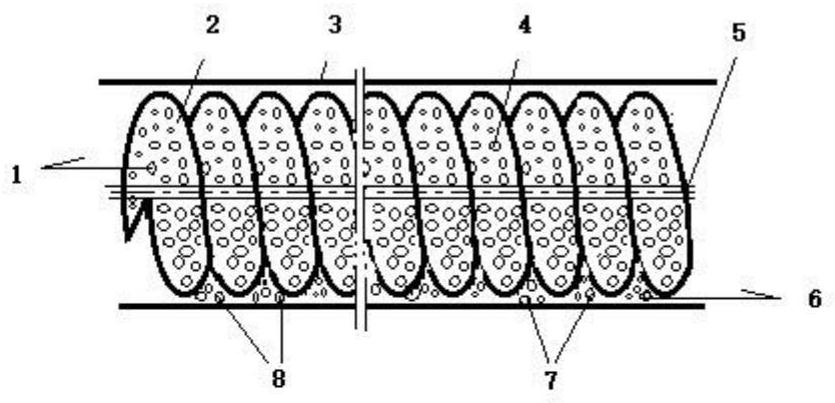

Method used

Image

Examples

Embodiment 1

[0022] Remove foreign matter, pedicles, twigs and other impurities from the freshly picked Sapindus fruit, sieve to remove dirt and other dust, rinse (drench) with cold water and clean it; use a suitable stainless steel plate to crush Sapindus fruit to make its surface There are certain cracks and cracks. Turn on the ultrasonic energy converter of the continuous extraction device to generate ultrasonic waves; at the same time turn on the hot water delivery pump, and add hot water that has been preheated to 95°C into the extraction pipeline from the liquid filling port at the other end of the continuous extraction device; Put the fresh fruit into the feeding funnel of the continuous extraction device, turn on the motor of the feeding threaded vortex impeller, and slowly push the sapinberry fruit forward into the extraction pipe; Assisted, continuous countercurrent extraction.

[0023] Control the running speed of the motor of the screw vortex impeller so that the residence tim...

Embodiment 2

[0026] Take the dried fruit of Sapindus chinensis after drying, remove impurities such as twigs and foreign objects, peel off the peel and core with a Sapindus fruit core peeling machine, sieve to remove impurities such as stalks and soil, and set aside. Turn on the ultrasonic energy converter of the continuous extraction device to generate ultrasonic waves; at the same time turn on the hot water delivery pump, and add hot water that has been preheated to 80°C into the extraction pipeline from the liquid filling port at the other end of the continuous extraction device; Dried fruit peels are added to the feeding hopper of the continuous extraction device, and the motor of the feeding threaded vortex impeller is turned on, so that the fruit peels of Sapindus chinensis are slowly pushed forward into the extraction pipeline; the peels of Sapinsia chinensis are contacted with hot water, and ultrasonic-assisted, continuous countercurrent extraction of saponin is carried out .

[00...

Embodiment 3

[0030] Take the dried fruit of Sapindus chinensis after drying, remove impurities such as twigs and foreign objects, peel off the peel and core with a Sapindus fruit core peeling machine, sieve to remove impurities such as stalks and soil, and set aside. Turn on the ultrasonic energy converter of the continuous extraction device to generate ultrasonic waves; at the same time, turn on the hot water delivery pump, and add hot water that has been preheated to 55°C into the extraction pipeline from the liquid filling port at the other end of the continuous extraction device; Dried fruit peels are added to the feeding hopper of the continuous extraction device, and the motor of the feeding threaded vortex impeller is turned on, so that the sapinberry fruit is slowly pushed forward into the extraction pipeline; Continuous countercurrent extraction.

[0031] Control the running speed of the motor of the screw vortex impeller so that the residence time of the fresh Sapindus fruit in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com