Casting green sand, environment-friendly carbonaceous additive and preparation process of environment-friendly carbonaceous additive

An environmentally friendly, additive technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] According to an exemplary embodiment of another aspect of the present disclosure, there is provided a method for preparing the above-mentioned environmentally friendly carbonaceous additive for foundry green sand, the preparation method comprising: adding microcrystalline graphite, titanium slag extract, and gas The slag raw material is ground and passed through a 200-mesh sieve, and the mass ratio is 60-80: 0-20: 0-20, for example (61-79): (1-19): (1-19), and for example (70 ~75): (5~15): (5~15), weigh the finely ground raw materials and place them in a mixer, stir and mix them evenly to obtain an environmentally friendly carbonaceous additive for casting green sand.

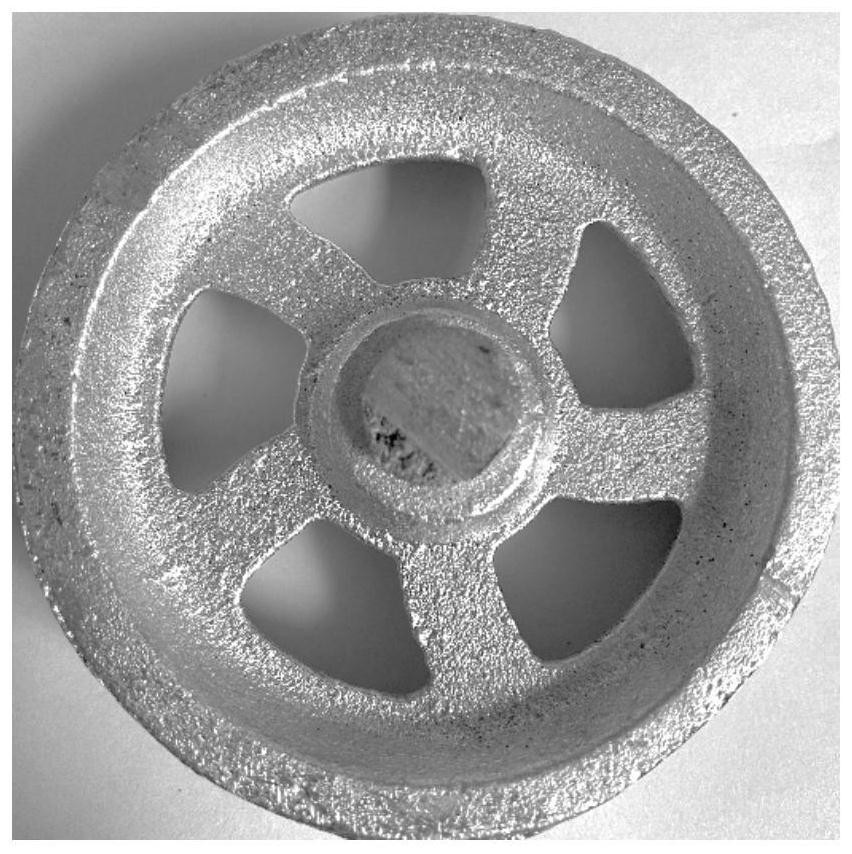

[0041] According to another exemplary embodiment of the present disclosure, there is provided a casting green sand, characterized in that the casting green sand comprises 100 parts by mass of quartz sand, 8-10 parts by mass of sodium bentonite and 3-7 parts by mass of Environmentally friendly carbonaceou...

example 1

[0045] The "carbon" in microcrystalline graphite, titanium extraction slag and coal gasification slag are pretreated to obtain 200 mesh (particle size<75μm) microcrystalline graphite, titanium extraction slag extract and coal gasification slag powder; The proportion is 80:0:20. The powder is weighed and placed in a mixer to stir and mix evenly to obtain the environmentally friendly carbonaceous additive for foundry green sand.

[0046] With the quartz sand (70 / 140 mesh) mass fraction as 100, the mass fraction of sodium bentonite as 8, the mass fraction of the prepared foundry green sand with environment-friendly carbonaceous additive is 5, will successively weigh the The material is put into the roller type sand mixer for sand mixing, and the compactness rate of the sample is controlled at 45±2%, and a 50mm±1% cylindrical sample and a 30mm±1% strip sample are made by a hammer sample making machine. sample and test its performance.

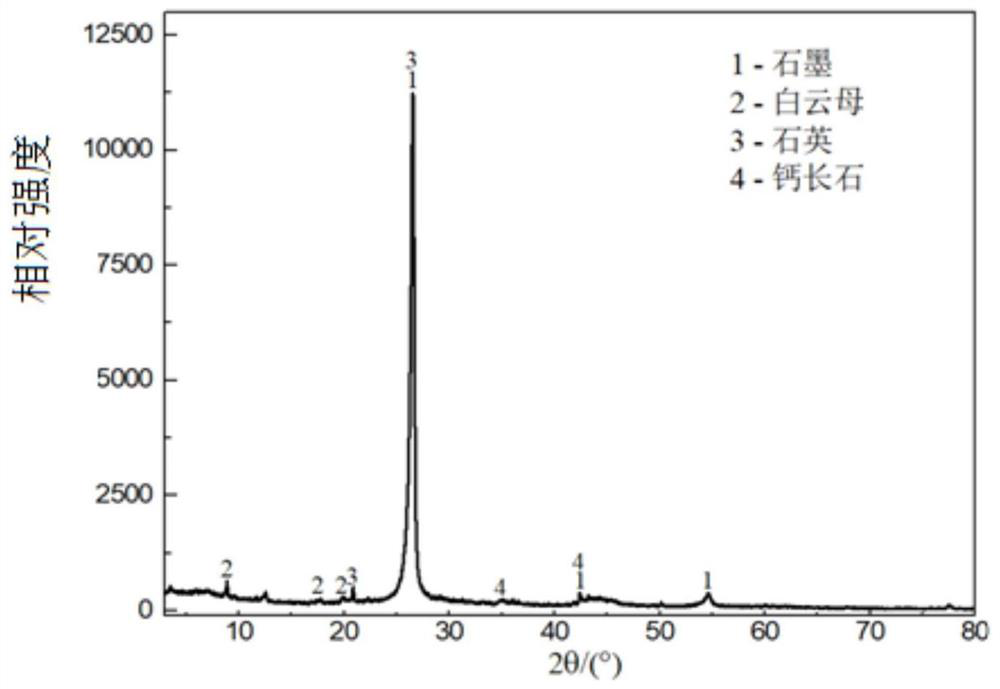

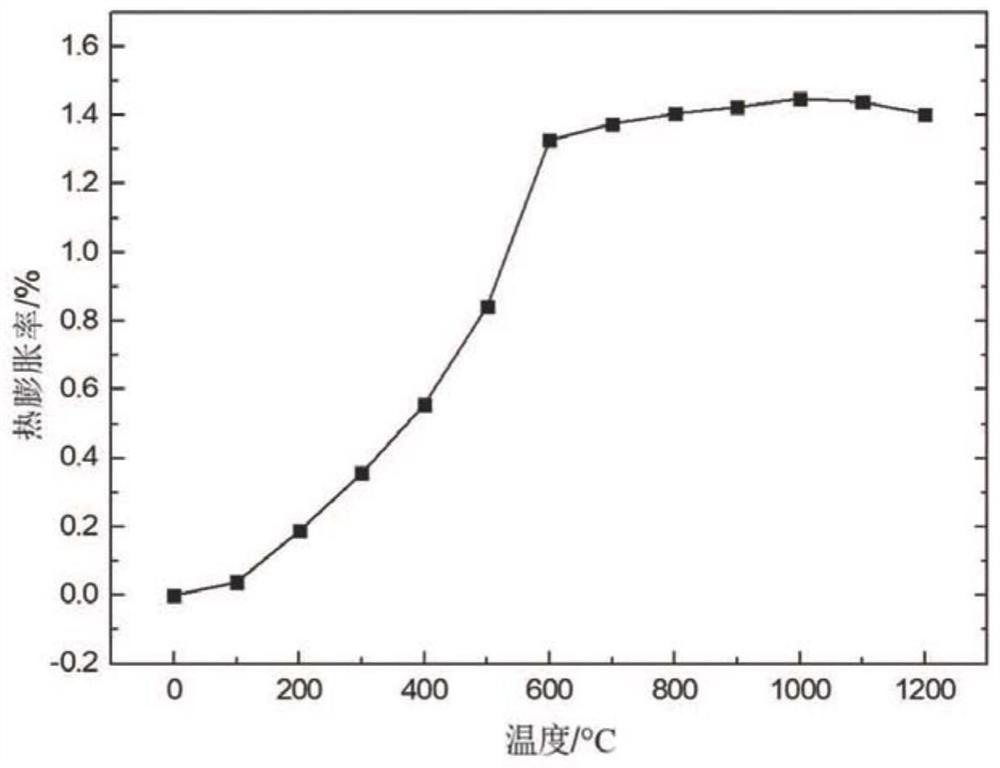

[0047] The mass percent content of the mine...

example 2

[0049] Microcrystalline graphite, titanium extraction slag extract and coal gasification slag are pretreated to obtain 200 mesh (particle size<75 μm) microcrystalline graphite, titanium extraction slag extract and coal gasification slag powder respectively; the mass percentage is 80 : The ratio of 10:10 weighs the powder and puts it in a mixer to stir and mix evenly to obtain the environmentally friendly carbonaceous additive for foundry green sand.

[0050] With the quartz sand (70 / 140 mesh) mass fraction as 100, the mass fraction of sodium bentonite as 10, the mass fraction of the prepared foundry green sand with environment-friendly carbonaceous additive is 5, will successively weigh the The material is put into the vertical flat mouth sand mixer for sand mixing, and the compactness rate of the sample is controlled at 45±2%, and the cylindrical sample of 50mm±1% and the bar shape of 30mm±1% are made by the hammer sample making machine Samples to test their related propertie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wet compressive strength | aaaaa | aaaaa |

| wet compressive strength | aaaaa | aaaaa |

| wet compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com