Optimized process method for improving stability of lactic acid bacteria cells

A process method and stability technology, applied in the field of lactic acid bacteria, can solve the problems of reduced number of viable bacteria and low stability, and achieve the effect of improving stability and extending shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

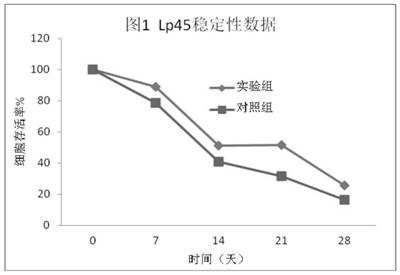

[0037] This example uses Lactobacillus plantarum Lp45.

[0038] test group:

[0039] S1. Spread the bacterial strain on the plate on the improved MRS agar solid medium, culture it upside down at 37°C for 48h, and screen for colonies with a smaller calcium-dissolving circle than 10% or less. The improved MRS agar solid medium includes the following groups Divide: peptone 8g, beef extract 8g, yeast extract 5g, diammonium hydrogen citrate 3g, glucose 15g, Tween 80 0.5ml, sodium acetate 4g, dipotassium hydrogen phosphate 1g, magnesium sulfate 0.6g, manganese sulfate 0.2g, agar 20g, 0.4g of L-cysteine hydrochloride, 1L of water, the pH is controlled at 6.4 ± 0.1, 8g of calcium carbonate is also added to the improved MRS agar medium; the screening is repeated 20 times;

[0040] S2. Fermentation and cultivation after the tertiary seed cultivation of the bacterium obtained in S1, the tertiary cultivation is respectively:

[0041] (1) First-level seed culture: Pick a single colony ...

Embodiment 2

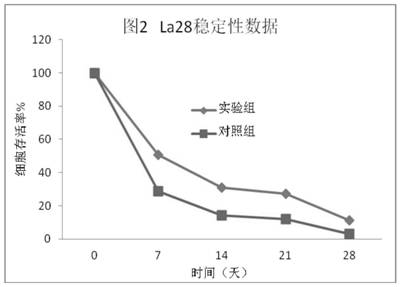

[0054] This example uses Lactobacillus acidophilus La28.

[0055] test group:

[0056] S1. Spread the bacterial strain on the plate on the improved MRS agar solid medium, culture it upside down at 37°C for 48h, and screen for colonies with a smaller calcium-dissolving circle than 10% or less. The improved MRS agar solid medium includes the following groups Divide: peptone 10g, beef extract 10g, yeast extract 4g, diammonium hydrogen citrate 2g, glucose 20g, Tween 80 1ml, sodium acetate 5g, dipotassium hydrogen phosphate 2g, magnesium sulfate 0.5g, manganese sulfate 0.3g, agar 15g , 0.8g of L-cysteine hydrochloride, 1L of water, the pH is controlled at 6.3 ± 0.1, 12g of calcium carbonate is also added to the improved MRS agar medium, and the screening is repeated 25 times;

[0057] S2. Fermentation and cultivation after the tertiary seed cultivation of the bacterium obtained in S1, the tertiary cultivation is respectively:

[0058] (1) First-level seed culture: pick a single...

Embodiment 3

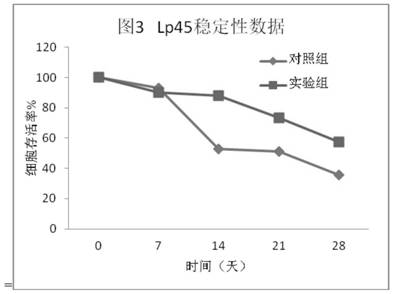

[0071] This example uses Lactobacillus plantarum Lp45.

[0072] test group:

[0073] S1. Spread the bacterial strain on the plate on the improved MRS agar solid medium, culture it upside down at 37°C for 48h, and screen for colonies with a smaller calcium-dissolving circle than 10% or less. The improved MRS agar solid medium includes the following groups Divide: peptone 8g, beef extract 8g, yeast extract 5g, diammonium hydrogen citrate 3g, glucose 15g, Tween 80 0.5ml, sodium acetate 4g, dipotassium hydrogen phosphate 1g, magnesium sulfate 0.6g, manganese sulfate 0.2g, agar 20g, 0.4g of L-cysteine hydrochloride, 1L of water, the pH is controlled at 6.4 ± 0.1, and 8g of calcium carbonate is also added in the improved MRS agar medium;

[0074] S2. Fermentation and cultivation after the tertiary seed cultivation of the bacterium obtained in S1, the tertiary cultivation is respectively:

[0075] (1) First-level seed culture: Pick a single colony from the solid plate medium into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com