High-elastic antibacterial eco-friendly dressing and preparation method thereof

A friendly and ecological technology, applied in the fields of filament/thread forming, medical science, non-woven fabrics, etc., can solve the problems of large expansion and contraction, the dressing can not fit the joint skin well, environmental hazards, etc., and is conducive to stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

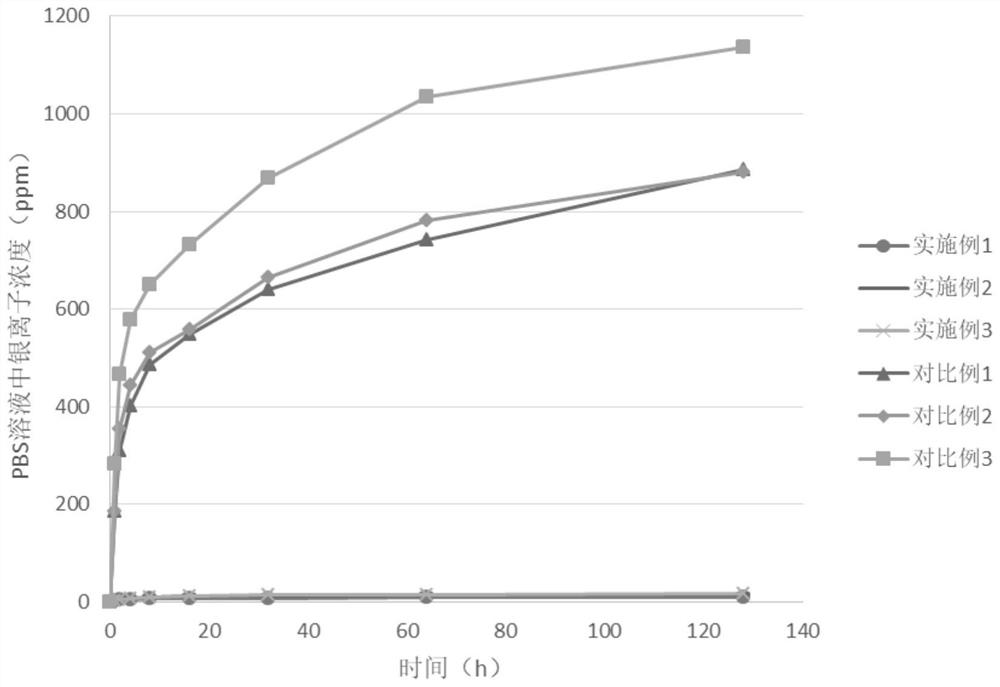

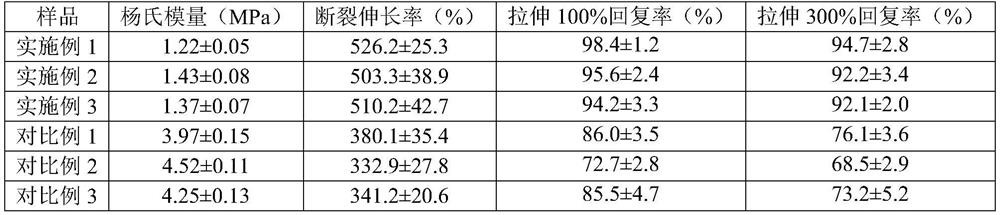

[0027] A high-elastic antibacterial eco-friendly dressing and a preparation method thereof, comprising the steps of:

[0028] 1. Wash and dry 5g of human nails, crush them, soak them together with 0.35g of sodium sulfide in 20ml of 40% liquid caustic soda solution at 90°C for 16 hours, filter them, and obtain the retentate by ultrafiltration with a molecular weight cut-off of 5000, spray Dried human nail keratin;

[0029] 2. Add 1g of human nail keratin, 12g of zein, 4g of polypyrrole with a conductivity of 30S / cm and 4g of thermoplastic polyurethane elastomer with a glass transition temperature of 110°C to 100ml of dimethyl ethyl alcohol prepared in step 1. In the amide, after fully stirring, the slurry is spray-dried to obtain the precursor powder;

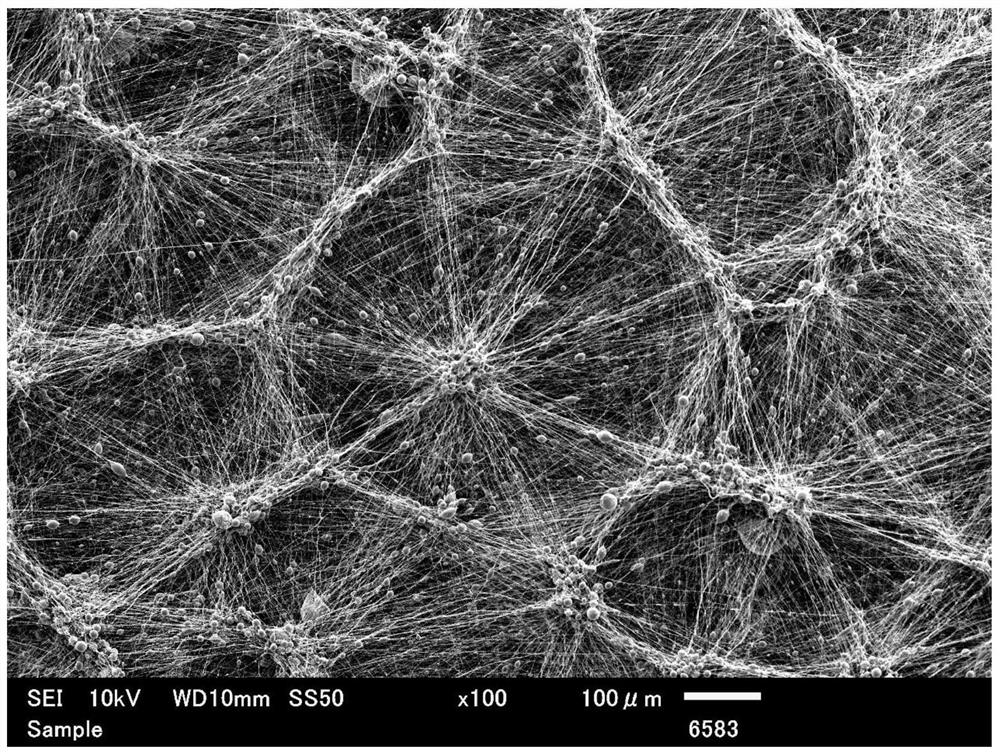

[0030] 3. Heat and melt the precursor powder prepared in step 2 under a nitrogen atmosphere, and perform melt electrospinning at a temperature of 190°C, a voltage of 18kv, a distance of 18cm, and an injection rate of 1.5ml / h to...

Embodiment 2

[0033] A high-elastic antibacterial eco-friendly dressing and a preparation method thereof, comprising the steps of:

[0034] 1. Wash and dry 5g of human nails, crush them, soak them together with 0.3g of sodium sulfide in 15ml of 40% liquid caustic soda solution at 80°C for 12h, filter them, and obtain the retentate by ultrafiltration with a molecular weight cut-off of 5000, and spray Dried human nail keratin;

[0035] 2. Add 0.5g of human nail keratin prepared in step 1, 10g of zein, 3g of polypyrrole with a conductivity of 10S / cm and 2g of thermoplastic polyurethane elastomer with a glass transition temperature of 100°C to 100ml of dimethyl In acetamide, after fully stirring, the slurry is spray-dried to obtain a precursor powder;

[0036] 3. Heat and melt the precursor powder prepared in step 2 under a nitrogen atmosphere, and perform melt electrospinning at a temperature of 180°C, a voltage of 15kv, a distance of 15cm, and an injection rate of 1ml / h to obtain fibers mem...

Embodiment 3

[0039] A high-elastic antibacterial eco-friendly dressing and a preparation method thereof, comprising the steps of:

[0040] 1. Wash and dry 5g of human nails, crush them, soak them together with 0.4g of sodium sulfide in 25ml of 40% liquid caustic soda solution at 100°C for 18 hours, filter them, and obtain the retentate by ultrafiltration with a molecular weight cut-off of 5000, spray Dried human nail keratin;

[0041] 2. Add 2g of human nail keratin, 15g of zein, 5g of polypyrrole with a conductivity of 50S / cm and 5g of thermoplastic polyurethane elastomer with a glass transition temperature of 125°C to 100ml of dimethyl ethyl alcohol prepared in step 1. In the amide, after fully stirring, the slurry is spray-dried to obtain the precursor powder;

[0042] 3. Heat and melt the precursor powder prepared in step 2 under a nitrogen atmosphere, and conduct melt electrospinning at a temperature of 200°C, a voltage of 20kv, a distance of 20cm, and an injection rate of 2ml / h to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com