Application of pollutant control in coal combustion process based on directional adjustment of fly ash mineral composition

A technology of mineral composition and fly ash is applied in the application field of pollutant control in the coal combustion process to achieve the effects of improving processing capacity, low system resistance and reducing operating load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

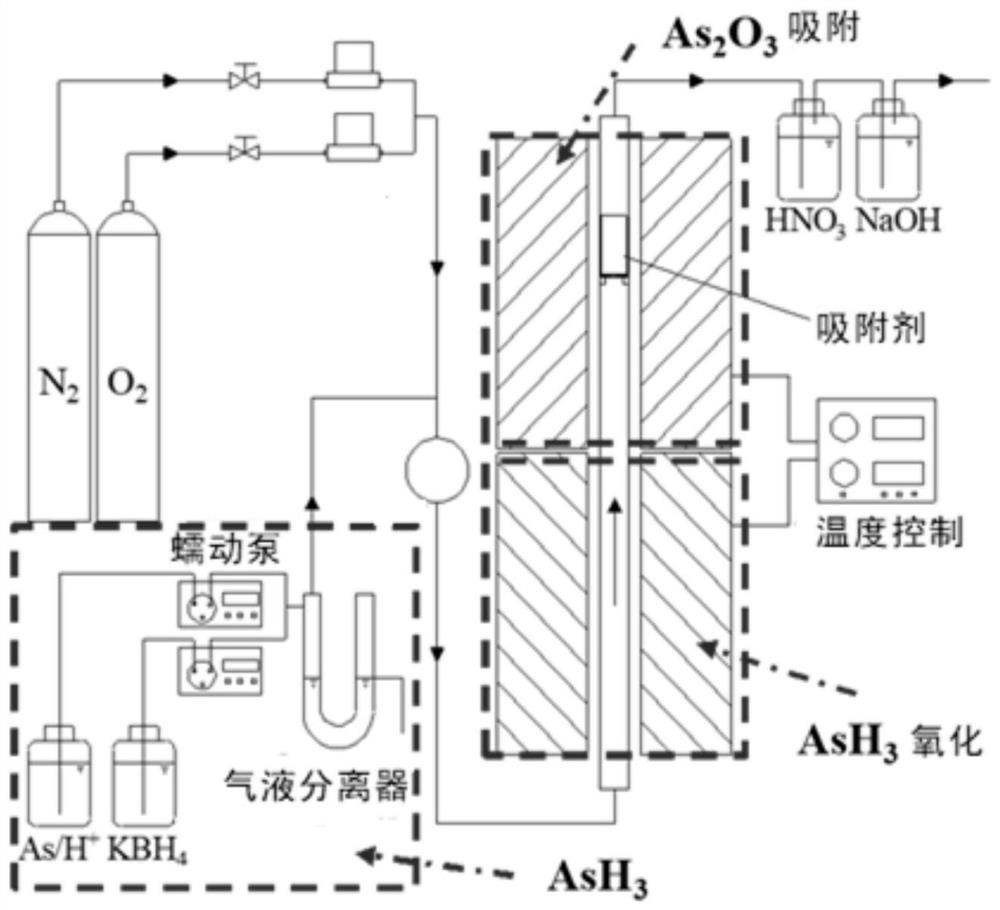

Method used

Image

Examples

Embodiment 1

[0041] Two types of fly ash were collected from two coal-fired power plants in Hubei Province. One type of fly ash comes from power plants that burn high-sulfur coal and is called high-sulfur fly ash GS. The other is to collect burning low-sulfur coal from power plants and name it low-sulfur fly ash DS.

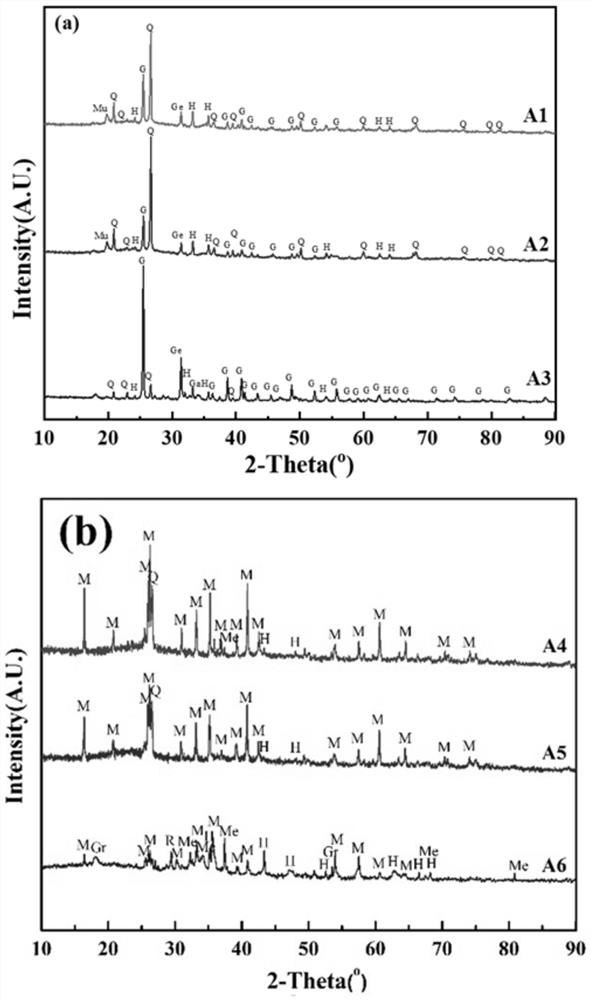

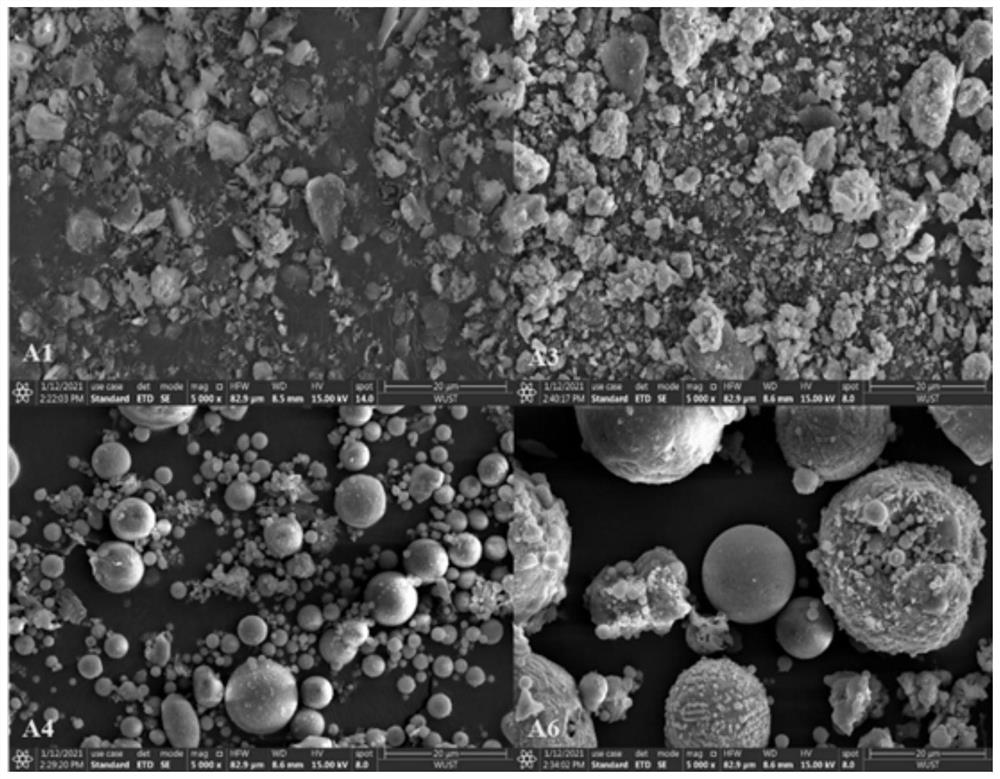

[0042] Gravity separation method was adopted, using gravity solution (2.89g / cm 3 ) Both low-sulfur fly ash DS and high-sulfur fly ash GS were separated into two parts: the low-sulfur fly ash DS and high-sulfur fly ash GS were dried in an oven at 45 °C for 24 h, and then mixed with bromoform (CHBr 3 , the density is 2.89g / cm 3 ) in a centrifuge tube for 10min, the rotating speed is 3000r / min, the components with higher density sink, and the low-sulfur fly ash DS and high-sulfur fly ash GS are separated into two parts. In this study, A1, A2, and A3 are the raw fly ash, gravity-separated light fly ash, and heavy fly ash, respectively, extracted from high-sulfur coal after cal...

Embodiment 2

[0062] It is well known that acid gases in flue gas, especially SO 2 , which may compete with arsenic to occupy the active sites on the adsorbent surface. Therefore, this example studies SO 2 Effects on the capture of arsenic by these 6 adsorbents.

[0063] The fly ash A1, A2 and A3 obtained after calcination of the high-sulfur pulverized coal in Example 1 were used as adsorbents. Then, 500ppm and 1500ppm of SO were added to the gas mixture generated by the arsenic generating system of Example 1, respectively. 2 , the mixed gas flows through 300 mg of adsorbent according to the flow rate and temperature set in Example 1, and the adsorption time is 1 h. After adsorption, the adsorbent used is cooled and collected for subsequent analysis. Each experiment was repeated three times to ensure reproducibility.

[0064] Adsorption capacity detection of adsorbents:

[0065] Different fly ash adsorbents in different SO at 700 ℃ 2 The adsorption capacity of arsenic at the concentra...

Embodiment 3

[0075] The raw fly ash A1, the light fly ash A2 and the heavy fly ash A3 after gravity separation, and the low-sulfur coal extracted after being calcined at 815° C. were used in Example 1. The original fly ash A4 and gravity-separated light fly ash A5 and heavy fly ash A6 are used as adsorbents to remove the polluting SO in the flue gas at the same time. 2 / NO X / toluene / chlorobenzene / As 2 O 3 , put A1, A2, A3, A4, A5, A6 in the fixed bed to test the adsorption performance of the adsorbent for 4 pollutants. At room temperature, the adsorbent is 10g, the simulated flue gas flow is 200ml / min, and the The concentration at the entrance is 1500, 500, 400, 400, 60 mg / Nm 3 the SO 2 / NO X / toluene / chlorobenzene / As 2 O 3 , also press NOx and NH 3 The concentration ratio of 1:1 mixed with NH 3 , the adsorption process is over, the adsorbent is weighed and SO 2 , NO X , Toluene, Chlorobenzene, As 2 O 3 After the weight change, the adsorption capacity of various adsorbents wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com