A biochemical pretreatment method for gallic acid production wastewater

A technology for gallic acid and wastewater production, applied in biological water/sewage treatment, natural water treatment, chemical instruments and methods, etc., can solve the problem of low COD removal rate, and achieve the effect of reducing COD, reducing inhibition, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

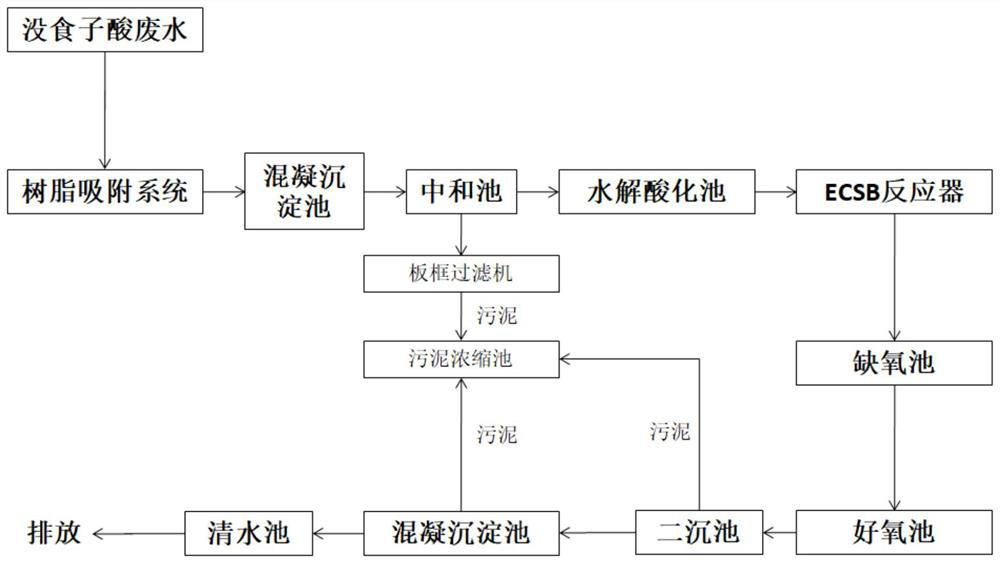

[0043] A biochemical pretreatment method for gallic acid production wastewater, comprising the following steps: the process flow is as follows figure 1As shown, including sequentially connected resin adsorption system, water distribution tank, neutralization tank, plate and frame filter, hydrolysis acidification tank, ECSB reactor, anoxic tank, aerobic tank and secondary sedimentation tank, coagulation sedimentation tank, clear water tank .

[0044] First, the resin adsorption system is used to recycle waste water. The crude gallic acid mother liquor is pretreated by precipitation and filtered, and then enters the resin adsorption system to recover the gallic acid in the mother liquor, and at the same time greatly reduce the COD of the wastewater, and the effluent enters the high-concentration regulating pool. After resin adsorption and separation treatment, more than 85% of the gallic acid in the wastewater can be recycled, and at the same time reduce more than 30% of the CO...

Embodiment 2

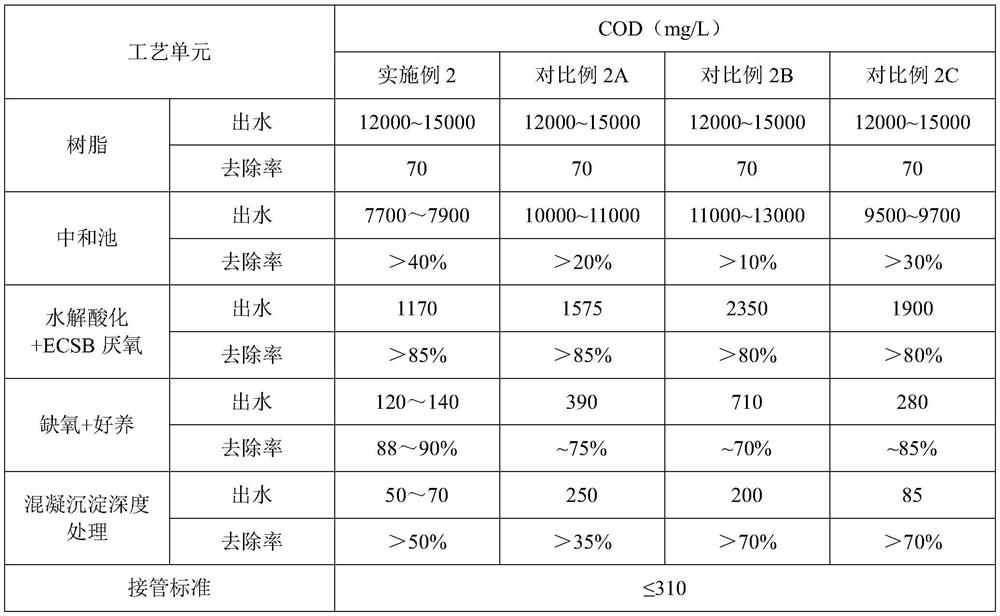

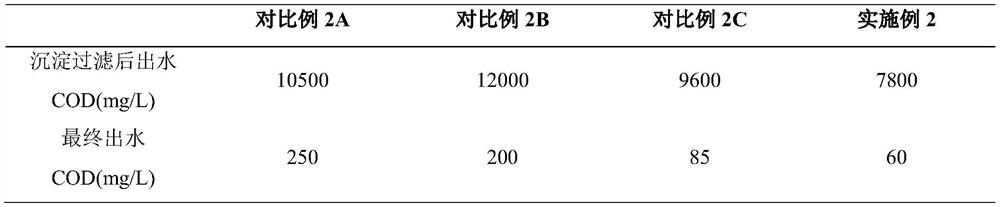

[0059] The process route in Example 1 is used to treat gallic acid production wastewater, wherein the resin adopts D201, and its adsorption rate for gallic acid in the thick mother liquor wastewater of gallic acid is 99%; the gallic acid in the resin treatment effluent wastewater is about 80mg / L , the mass concentration of sulfate radicals is 600mg / L, as shown in Table 1. First, adjust the pH of the wastewater to 6.5-7.5 with 30% sodium hydroxide solution, and then add calcium chloride solution to the neutralization tank twice. And in the pool, calculate the concentration of the substance that adds calcium ions for the first time according to the following empirical formula:

[0060] no A =k 1 no 1

[0061] Among them, n A is the mass concentration of the calcium ion added for the first time, n 1 is the amount concentration of sulfate radical in wastewater, k 1 is the empirical coefficient, the empirical coefficient k 1 is 0.2.

[0062] From the above, it can be seen t...

Embodiment 3

[0100] In this embodiment, calcium ions are prepared from calcium hydroxide solution prepared from refined lime to increase the effective content of calcium oxide, reduce impurities and reduce the blockage of pipelines and water pumps, and reduce sludge production at the same time.

[0101] The process route in the embodiment 1 is adopted to process the gallic acid production waste water, the water quality of the waste water is basically the same as in the embodiment 2, wherein the resin adopts D201, and its adsorption rate for gallic acid in the thick mother liquor waste water of gallic acid is 99%; first use 15% sodium hydroxide solution to adjust the pH of the wastewater to 4-5, and then add calcium hydroxide solution to the neutralization tank twice, and calculate the concentration of the first calcium ion in the neutralization tank according to the following empirical formula for:

[0102] no A =k 1 no 1

[0103] Among them, n A is the mass concentration of the calci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com