Magnesium-containing compound modified Ti-HMS/carbon nanofiber composite catalyst and preparation and application thereof

A technology of carbon nanofibers and composite catalysts, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of synthesis process defects, short catalyst life, etc., and achieve high product selectivity and enhanced anti-coking performance. , the effect of improving the hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

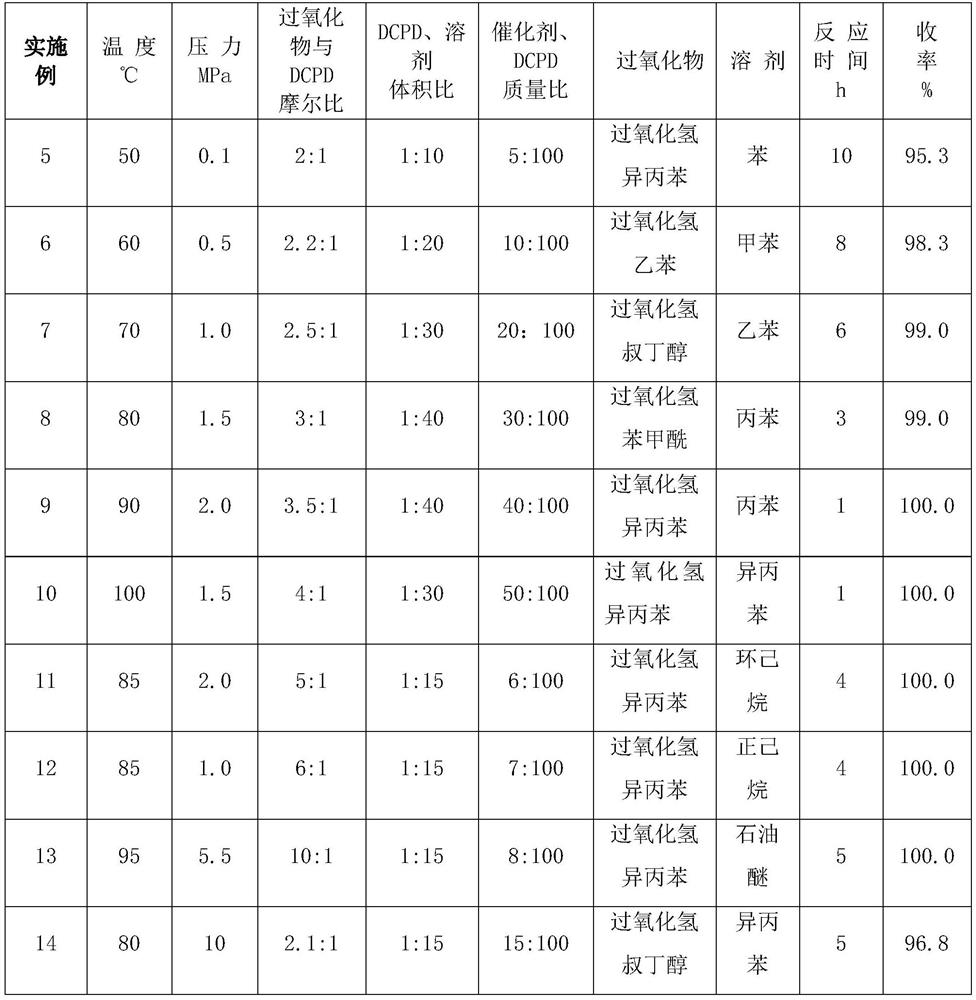

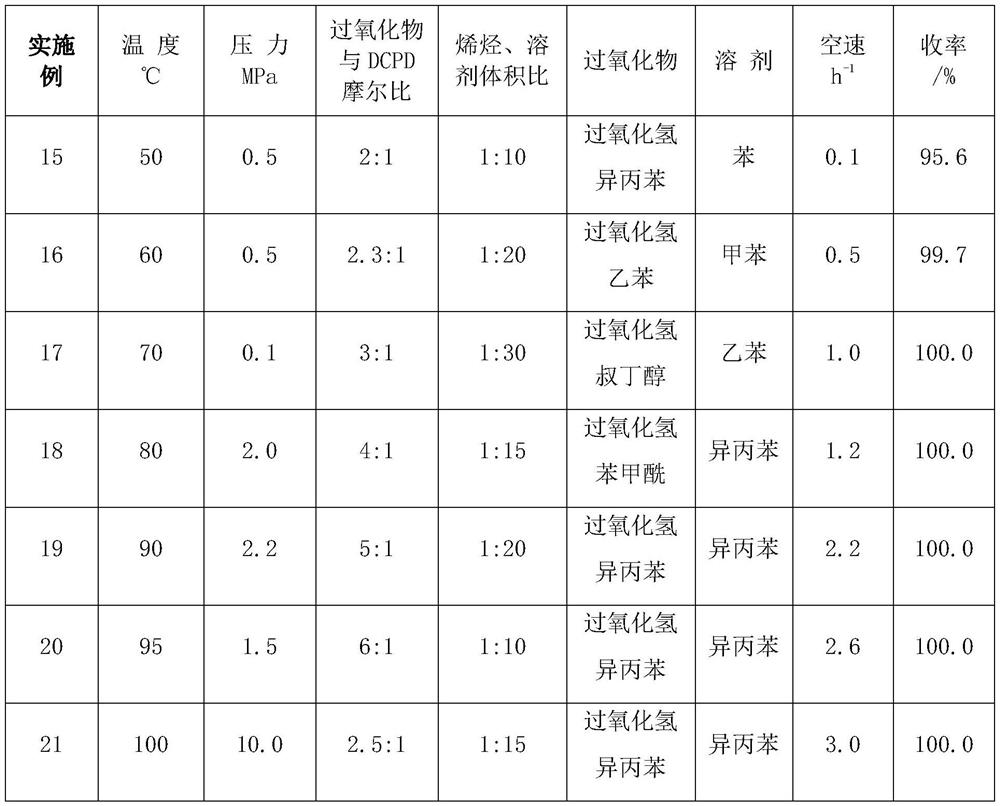

Examples

Embodiment 1

[0037] At room temperature and under stirring conditions, add 23 grams of hexadecylamine to 112 ml of water and 110 milliliters of ethanol successively in the reactor, and stir; Add it into the above solution, stir for 30 minutes, crystallize for 12 hours, add 74.9 grams of carbon nanofibers, continue stirring for 10 to 72 hours, heat up the reactor, and crystallize the reaction material at 200 ° C for 1 day, filter to obtain a solid, and extract the catalyst with ethanol template agent, and then washed with pure water until the eluent was neutral. After drying the washed solid at 110° C. for 12 hours, Ti-HMS supported by carbon nanofibers was obtained.

[0038] Add 3 times the volume of pure water, 0.54 grams of Mg(OH) 2 , room temperature, stirred for 48 hours, separated the solid, washed with pure water until the washing liquid was neutral, dried at 80°C for 20 hours, and then calcined at 400°C for 20 hours in a helium atmosphere to obtain magnesium-containing compound mod...

Embodiment 2

[0041] At room temperature and under stirring conditions, add 15 grams of dodecylamine successively to 80 ml of water and 40 ml of ethanol in the reactor, and stir; Add it to the above solution, stir for 30 minutes, crystallize for 6 hours, add 37.4 grams of carbon nanofibers, continue to stir for 60 hours, raise the temperature, the material in the reactor crystallizes at 150 ° C for 7 days, filter to obtain a solid, and extract it with ethanol to remove the catalyst. template agent, and then washed with pure water until the eluent was neutral. After drying the washed solid at 110° C. for 10 hours, Ti-HMS supported by carbon nanofibers was obtained.

[0042] Add the pure water 3 times the volume of the solid catalyst to the Ti-HMS solid with the above-mentioned carbon nanofiber as the carrier, 0.6 gram of MgCO 3 , 0.1 gram of MgO, at room temperature, stirring for 48 hours, separating the solid, washing with pure water until the washing liquid is neutral, drying at 80°C for ...

Embodiment 3

[0045] At room temperature and under stirring conditions, add 0.7 g of tetradecylamine to 22 ml of water and 60 ml of ethanol in turn during the reaction, and stir; add 65 g of ethyl orthosilicate and 5 g of ethyl titanate dissolved in 30 ml of ethanol Add to the above solution, stir for 30 minutes, crystallize for 6 to 12 hours, add 18.7 grams of carbon nanofibers, continue to stir for 10 to 72 hours, raise the temperature, and crystallize the reaction material at 150 ° C for 1 day, filter to obtain a solid, and extract the catalyst with ethanol Templating agent in . Then wash with pure water until the eluent is neutral. After drying the washed solid at 110° C., Ti-HMS supported by carbon nanofibers was obtained. Add the above-mentioned carbon nanofiber as the Ti-HMS solid of the carrier and add the same volume of pure water as the solid catalyst, 0.02 gram of basic magnesium carbonate (4MgCO 3 . Mg(OH) 2 .5H 2 (0), room temperature, stirring for 48 hours, separating the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com