Metal organic framework loaded solid heteropolyacid oxidative desulfurization catalyst as well as preparation method and application thereof

A metal-organic framework, solid heteropolyacid technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of uneven distribution and dispersion of POMs@MOFs In order to avoid the loss of catalyst active centers and reduce the catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

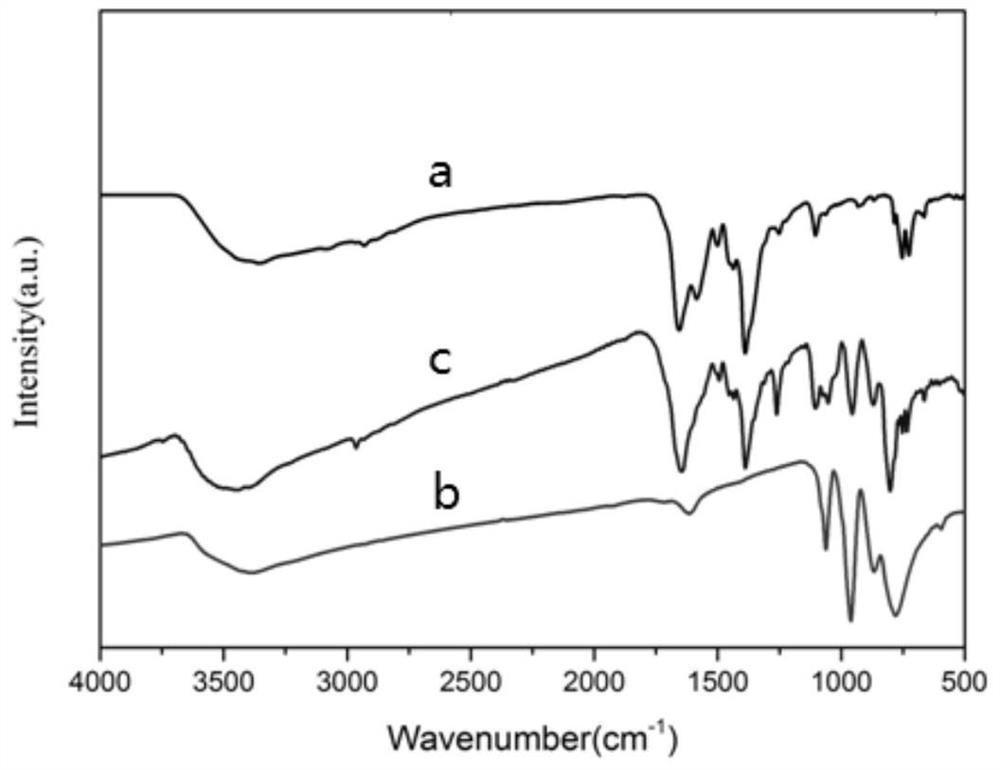

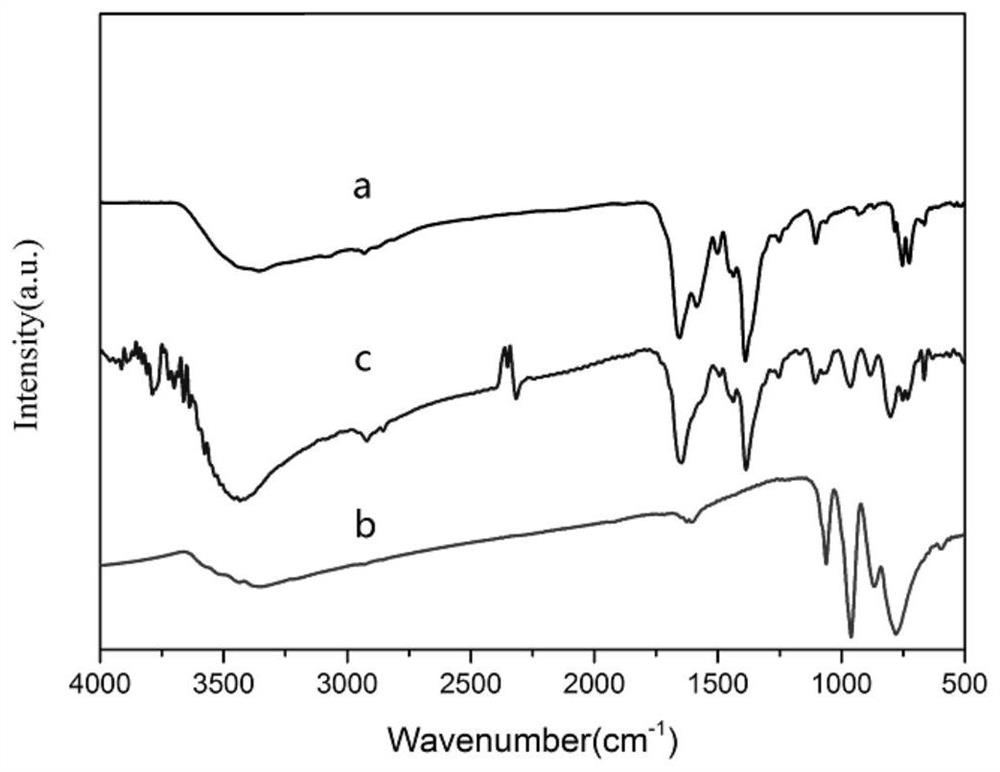

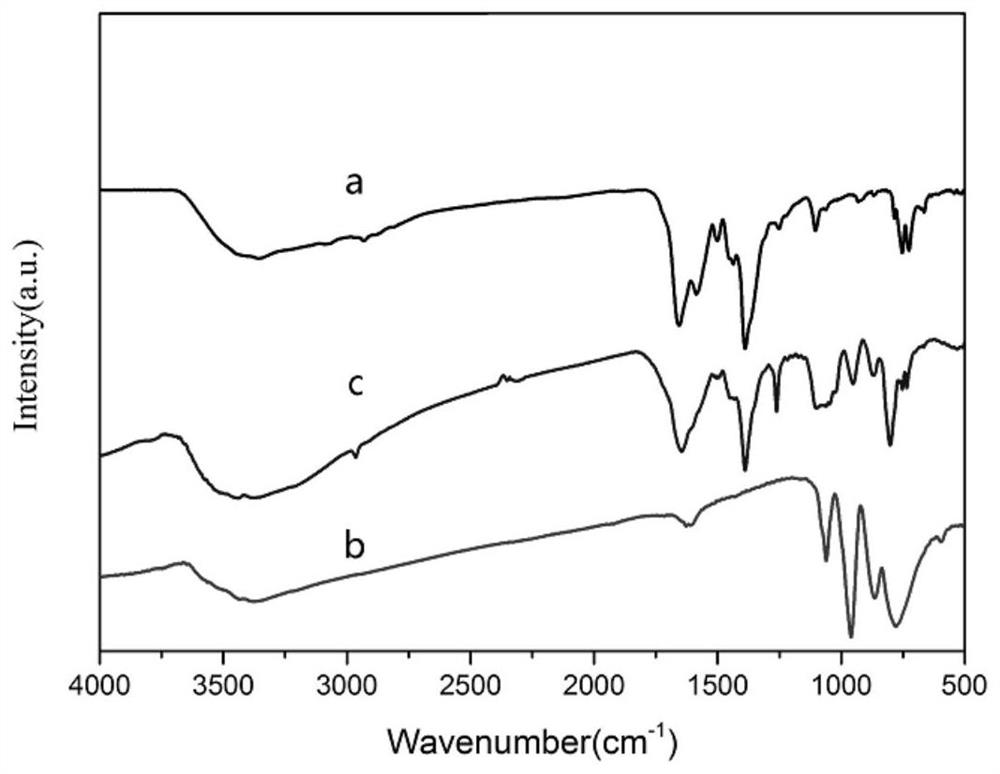

[0049] Embodiment 1: This embodiment is a metal-organic framework-supported solid heteropolyacid oxidative desulfurization catalyst, which is obtained by loading heteropolyacids in MOF; the MOF is rht-MOF-1; the The heteropolyacid is a Keggin type ternary phosphorus tungsten vanadium saturated heteropolyacid, and its general structure is H 3+n PW 12-n Vn o 40 ·nH 2 O, wherein n=1~3; or the heteropolyacid is a Keggin type ternary phosphomolybdenumtungsten saturated heteropolyacid, and its general structural formula is H 3 PMo (12-n) W n o 40 ·nH 2 O, wherein n=1~3; or described heteropolyacid is Keggin type ternary silicon molybdenum vanadium saturated heteropolyacid, and its general structural formula is H 3+n SiMo (12-n) V n o 40 ·nH 2 O, wherein n=1-3.

[0050] The heteropolyacid described in this specific embodiment is a crystalline heteropolyacid.

[0051] The general structural formula of the rht-MOF-1 described in this specific embodiment is [Cu 6 O(TZI) 3...

specific Embodiment approach 2

[0059] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the heteropolyacid is loaded in the MOF by encapsulation. Others are the same as the first embodiment.

specific Embodiment approach 3

[0060] Specific embodiment three: This embodiment is a method for preparing a metal-organic framework-supported solid heteropolyacid oxidative desulfurization catalyst, which is prepared according to the following steps:

[0061] Add copper chloride, 5-tetrazolium isophthalic acid, and heteropolyacid into the mixed solution of DMF and deionized water, heat for 4h to 8h at a temperature of 70°C to 80°C, and then drop to At room temperature, a blue-green polyhedral crystal catalyst is obtained, that is, a metal-organic framework-supported solid heteropolyacid oxidative desulfurization catalyst;

[0062] The heteropolyacid is a Keggin type ternary phosphorus tungsten vanadium saturated heteropolyacid, and its general structural formula is H 3+n PW 12-n V n o 40 ·nH 2 O, wherein n=1~3; or the heteropolyacid is a Keggin type ternary phosphomolybdenumtungsten saturated heteropolyacid, and its general structural formula is H 3 PMo (12-n) W n o 40 ·nH 2 O, wherein n=1~3; or d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com