Method for synthesizing H2O2 through mechanical catalysis

A H2O2, mechanical technology, applied in the field of catalysis, can solve the problems of low carrier mobility, insufficient advantages, and lack of electrical properties, etc., to achieve the effect of expanding the application range, improving electrical conductivity, and enhancing reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

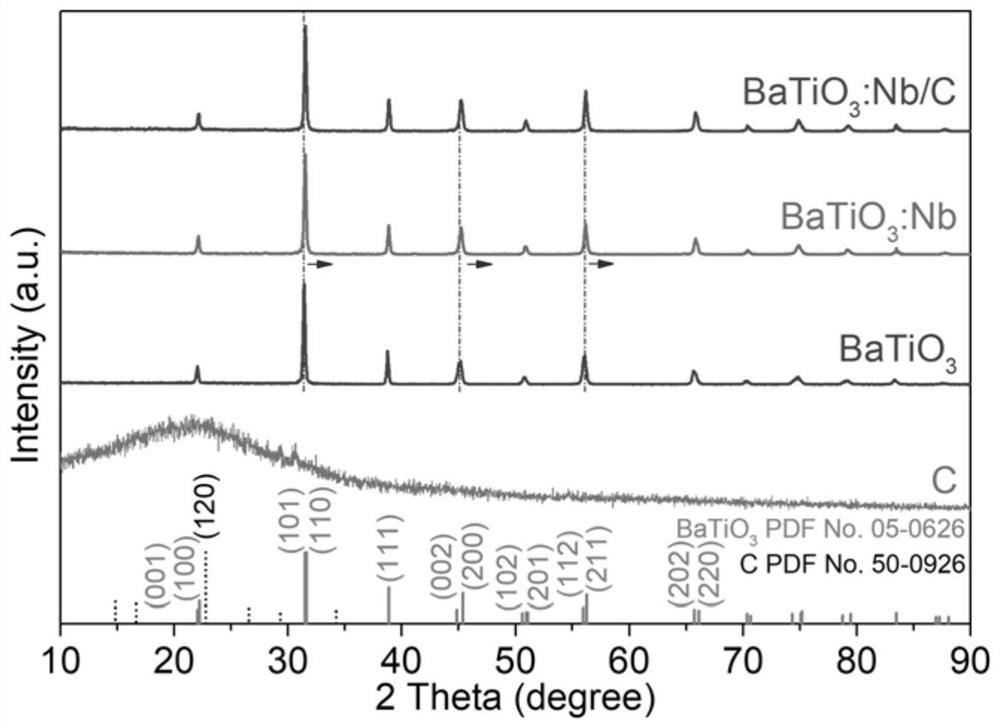

Embodiment 1

[0041] A Nb-doped modified tetragonal BaTiO 3 (BaTiO 3 : The preparation method of Nb), its main steps are as follows:

[0042] (1) Weigh 1.0 g of polyethylene glycol (PEG, relative molecular weight 6000) and dissolve it in 14 ml of ethanol-water mixed solution (the volume ratio of ethanol to water is 1:1), and stir magnetically for 10 min to form solvent A.

[0043] (2) Measure 500 μl tetrabutyl titanate solution, press NbCl 5 The molar ratio of tetrabutyl titanate to tetrabutyl titanate is 1:8~11, and the calculated amount of NbCl is weighed 5 , were added to 10ml of absolute ethanol, and ultrasonicated for 3min to form a light white suspension B. Then, liquid B was added dropwise to liquid A, and magnetically stirred for 15 min.

[0044] (3) Weigh 1.4g of sodium hydroxide and dissolve it in 12ml of ethanol-water mixed solution (the volume ratio of ethanol to water is 1:1), and add it dropwise into the fully reacted A liquid and B liquid mixed liquid, Stir magnetically ...

Embodiment 2

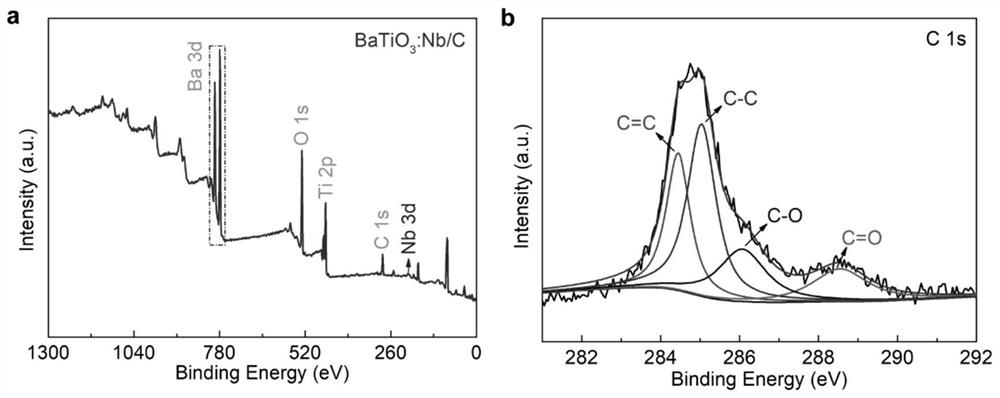

[0048] A Nb-doped Modified Tetragonal BaTiO Supported by C Quantum Dots 3 Preparation method of nanorod piezoelectric composite material (BaTiO 3 :Nb / C), its main steps are as follows:

[0049] (1) BaTiO prepared by C and Example 1 3 : The weight percentage of Nb is 0.6~1.8wt.%. Weigh the calculated amount of glucose and BaTiO 3 : Nb powder, dispersed in 30ml deionized aqueous solution, ultrasonic 15min, forming a milky white suspension.

[0050] (2) Transfer the milky white suspension to a closed autoclave, and place it in an oven at 180°C for 6 hours.

[0051] (3) After the reactor was cooled to room temperature, the reaction mixture was taken out, washed 3 to 5 times with deionized water and ethanol solution, and then dried in a 90°C drying oven for 12 hours to obtain BaTiO loaded with C quantum dots. 3 : Nb nanorod piezoelectric composite powder.

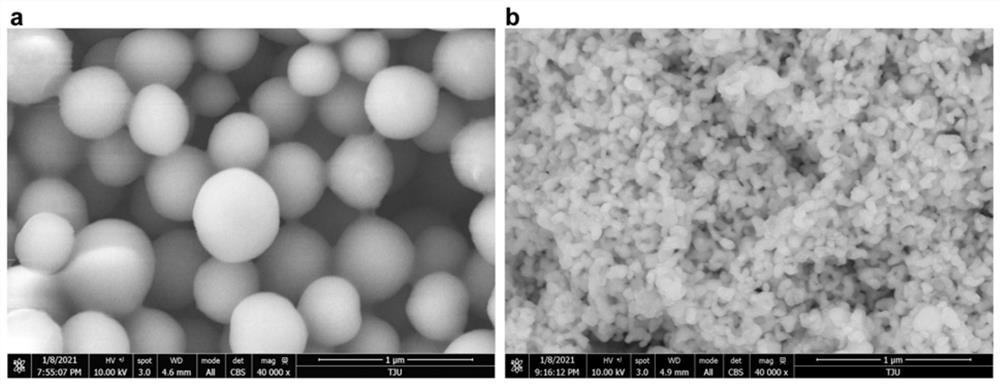

Embodiment 3

[0053] A preparation method of pure phase C, its main steps are as follows:

[0054] (1) First weigh 0.75g of glucose and dissolve it in 30ml of deionized water, then transfer it to an autoclave, and react at 160-200°C for 4-8 hours.

[0055] (2) After the reaction kettle was cooled to room temperature, the reaction mixture was taken out and washed with deionized water and ethanol solution for 3 to 5 times, and then dried in a 90°C drying oven for 12 hours to obtain pure-phase nano-C particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com