High-titanium blast furnace slag high-strength lightweight aggregate and preparation method thereof

A high-titanium blast furnace slag and lightweight aggregate technology, which is applied in the field of concrete materials, can solve problems such as secondary pollution, low resource utilization, and complex processes, so as to improve the compressive bearing capacity, improve the composition and structure, and simplify the production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing high-strength lightweight aggregate of high-titanium blast furnace slag, comprising the following steps:

[0026] S1. Prepare the pulverized blast furnace slag, silicon-aluminum modified components, air-entraining agent and flux;

[0027] S2. Drying the materials in S1, then mixing the blast furnace slag, silicon-aluminum modified components, air-entraining agent and fluxing agent in proportion, and forming into balls to form raw meal balls of 6-10 mm;

[0028] S3. Put the raw meal balls obtained in S2 into the firing system through the kiln tail of the rotary kiln ceramsite production line for firing treatment to obtain high-strength and light aggregate of high-titanium blast furnace slag;

[0029] S4, discharging and cooling the high-titanium blast furnace slag high-strength light aggregate obtained in S3.

[0030] Wherein, the firing process is to send the dried raw meal balls into the rotary kiln, the rotating speed of the rotary kiln is 1.1r...

Embodiment 1

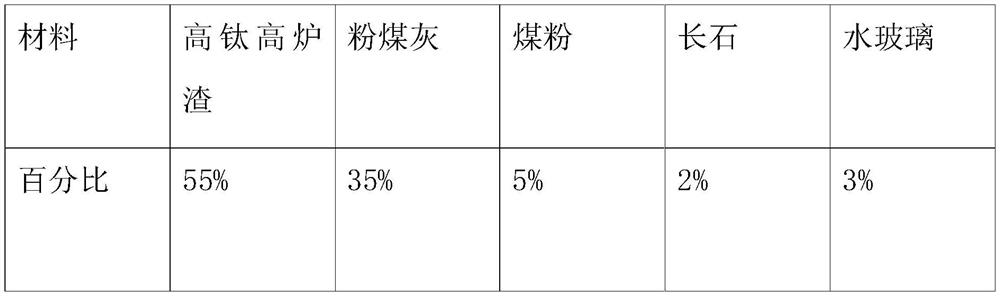

[0033] Embodiment 1, a kind of high-titanium blast furnace slag high-strength light aggregate, each component is calculated by mass percentage, high titanium blast furnace slag 55%, fly ash 35%, coal dust 5%, feldspar 2% and water glass 3 % mix composition.

[0034]

[0035] A method for preparing high-strength lightweight aggregate of high-titanium blast furnace slag, comprising the following steps:

[0036] S1. Prepare the blast furnace slag that has been pulverized, the specific surface area of high titanium blast furnace slag is 350m2 / kg, and fly ash, coal powder, feldspar and water glass;

[0037] S2, drying the materials in S1, and then mixing blast furnace slag, fly ash, coal powder, feldspar and water glass in proportion to form raw meal balls of 6-10 mm;

[0038] S3. Put the raw meal balls obtained in S2 into the firing system through the kiln tail of the rotary kiln ceramsite production line for firing treatment. ~1300℃) with a rotation speed of 2.8r / min, and ...

Embodiment 2

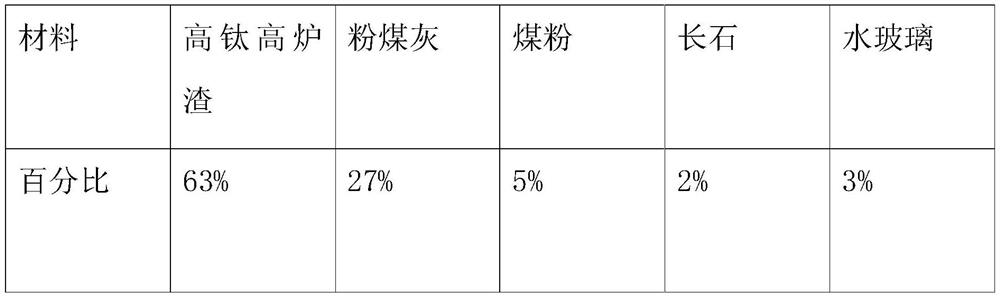

[0040] Embodiment 2, a high-strength light aggregate of high-titanium blast furnace slag, each component is counted by mass percentage, high-titanium blast furnace slag is 63%, fly ash 27%, coal dust 5%, feldspar 2% and water glass 3% mixed composition.

[0041]

[0042] A method for preparing high-strength lightweight aggregate of high-titanium blast furnace slag, comprising the following steps:

[0043] S1. Prepare the blast furnace slag that has been pulverized, the specific surface area of high titanium blast furnace slag is 350m2 / kg, and fly ash, coal powder, feldspar and water glass;

[0044]S2, drying the materials in S1, and then mixing blast furnace slag, fly ash, coal powder, feldspar and water glass in proportion to form raw meal balls of 6-10 mm;

[0045] S3. Put the raw material balls obtained in S2 into the firing system through the kiln tail of the rotary kiln ceramsite production line for firing treatment. ~1300℃) with a rotation speed of 2.8r / min, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com