Preparation method of modified coal ash and application of modified coal ash in metal powder coating

A metal powder and coal ash technology, which is applied in powder coatings, polyester coatings, chemical instruments and methods, etc., can solve the problems of weak antibacterial properties and high production costs, and achieve good metallic luster, high powder coating rate, and low production costs. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of described modified coal ash comprises the following steps:

[0054] Step 1: pickling the coal ash with hydrochloric acid with a mass concentration of 25.2%-30% until the pH value of the coal ash is 8.6-9.0, and then washing the acid-washed coal ash with water. After washing, the pH value of the coal ash is tested to be 7.2-7.5 After pressure filtration, it is processed into clean coal ash, and the clean coal ash is dried at a temperature of 70-76°C until the water content is ≤2.3%;

[0055] Step 2: Grinding the clean coal ash obtained in step 1, and sieving to obtain clean coal ash larger than 400 meshes;

[0056] Step 3: Add the first composite modifier to the clean coal ash obtained in step 2, and the first composite modifier consists of coconut oil fatty acid diacetamide, hexapylglycerol monostearate, N-oleoyl -N-Methyl taurine sodium composition, the addition of the first composite modifier is 4.2%-4.8% of the clean coal ash quality, the c...

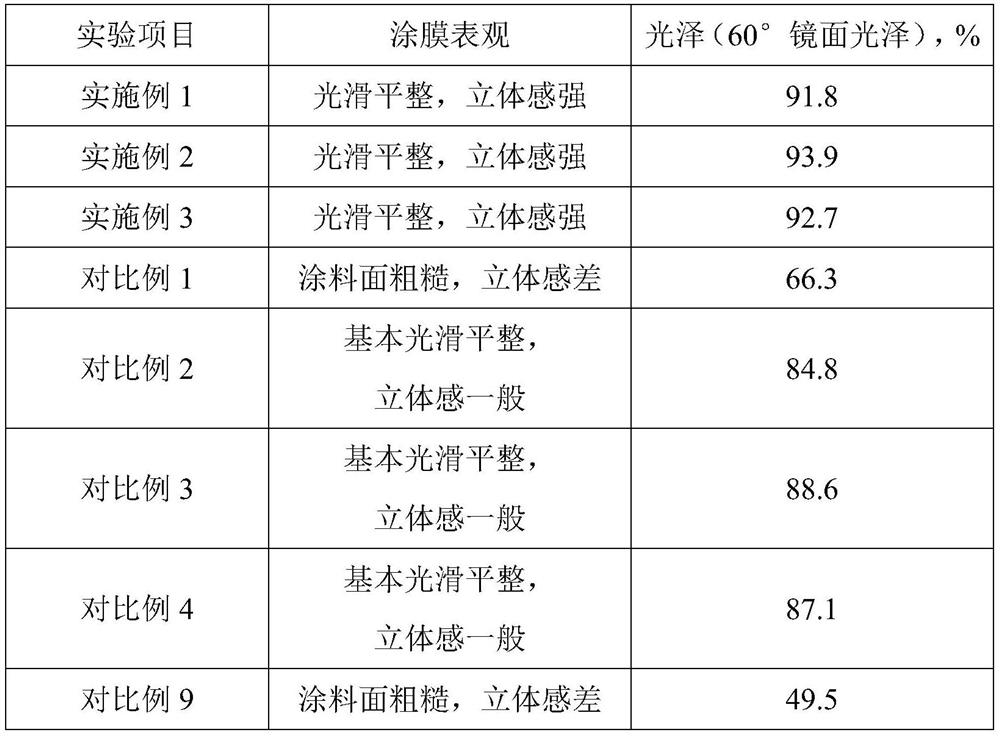

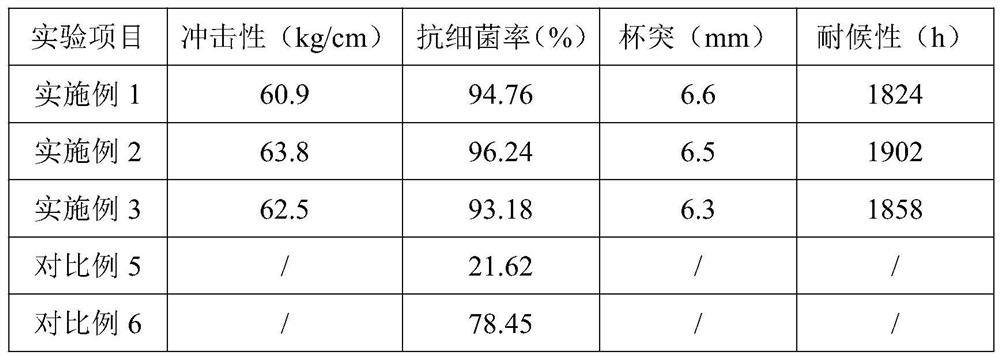

Embodiment 1

[0065] A metal powder coating, comprising the following raw materials in mass percentage: 31.5% of modified coal ash, 49.2% of polyester resin, 5.7% of curing agent, 1.4% of leveling agent, 0.6% of benzoin, 3% of wax powder, and 1% of brightening agent %, metallic pigments 7.6%.

[0066] The polyester resin is prepared by the method of Example 2 disclosed in the Chinese patent document "Polyester resin for indoor powder coatings and its preparation method (patent number: ZL201610735896.7)".

[0067] The curing agent is TGIC curing agent.

[0068] The leveling agent is leveling agent GLP588.

[0069] The brightener is brightener LD-608.

[0070] The metallic pigments include pearlescent pigments and copper-gold powders, wherein the pearlescent pigments are 5.2% and the copper-gold powders are 2.4%.

[0071] The preparation method of described modified coal ash comprises the following steps:

[0072]Step 1: Pickling the coal ash with hydrochloric acid with a mass concentrati...

Embodiment 2

[0087] A metal powder coating, comprising the following raw materials in mass percentage: 34.2% of modified coal ash, 47.6% of polyester resin, 5.6% of curing agent, 1.2% of leveling agent, 0.5% of benzoin, 2.7% of wax powder, and 0.9% of brightening agent %, metallic pigments 7.3%.

[0088] The polyester resin is prepared by the method of Example 2 disclosed in the Chinese patent document "Polyester resin for indoor powder coatings and its preparation method (patent number: ZL201610735896.7)".

[0089] The curing agent is TGIC curing agent.

[0090] The leveling agent is leveling agent GLP588.

[0091] The brightener is brightener LD-608.

[0092] The metallic pigments include pearlescent pigments and silver-aluminum powders, wherein the pearlescent pigments are 2.5% and the silver-aluminum powders are 4.8%.

[0093] The preparation method of described modified coal ash comprises the following steps:

[0094] Step 1: Pickling the coal ash with hydrochloric acid with a mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com