A kind of UV adhesion-reducing protective film that is easy to peel off and preparation method thereof

A protective film and easy-peeling technology, which is applied in the direction of film/sheet adhesives, adhesives, adhesive types, etc., can solve the problems of restricting UV adhesion-reducing protective films, low initial peeling force, and damage to electronic products. Achieve excellent UV viscosity reduction effect, long shelf life, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

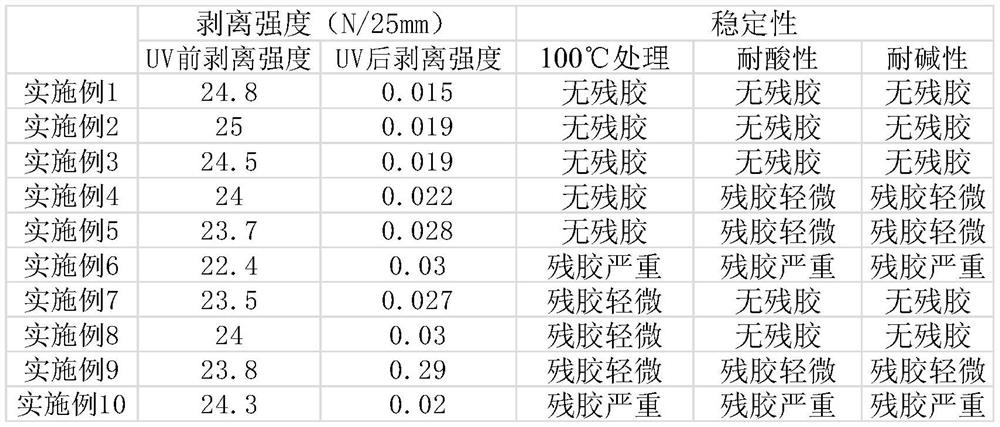

Examples

preparation example Construction

[0047] Second aspect of the present invention provides a kind of preparation method of easy-peelable UV debonding protective film, comprises the following steps:

[0048] 1) coating the cross-linking agent and primer on the surface of the substrate layer, drying and curing to form a primer layer on the surface of the substrate layer;

[0049] 2) Weigh the raw materials of each component of the adhesive layer according to the formula, add the acrylic acid monomer, accelerator, initiator, and diluent to the reaction vessel, then add ethyl acetate, mix and stir evenly, and evenly spread the obtained mixture on An adhesive layer is formed on the primer layer; a release film layer is pasted on the surface of the adhesive layer, and after reacting for 1.5-2 hours, it is cured to obtain the UV mucous-reducing film.

[0050] Preferably, the material of the protective film substrate layer includes but is not limited to polyethylene terephthalate, polyolefin, polyimide, polyether ether ...

Embodiment 1

[0062] An easy-peelable UV adhesion-reducing protective film comprises a protective film substrate layer, a primer layer, an adhesive layer and a release film layer from bottom to top.

[0063] The raw materials of the adhesive layer include, in parts by weight, 45 parts of acrylic acid monomer, 5 parts of accelerator, 2 parts of initiator and 30 parts of diluent.

[0064] The acrylic monomers include isooctyl acrylate, n-butyl acrylate, acrylic acid, methyl acrylate, and methyl methacrylate. The weight ratio of isooctyl acrylate, n-butyl acrylate, methacrylic acid, ethylene glycol dimethacrylate and methyl methacrylate is 10:8:3:5:0.8.

[0065] The accelerator includes tertiary amine compound, liquid paraffin and organic acid. The weight ratio of the tertiary amine compound, liquid paraffin and organic acid is 3:1:0.7.

[0066] The tertiary amine compound is N,N-dimethylaniline. The liquid paraffin was purchased from Xinji Haorui Petrochemical Co., Ltd.; the organic acid w...

Embodiment 2

[0080] An easy-peelable UV adhesion-reducing protective film, the specific implementation is the same as in Example 1, the difference is that the raw materials of the adhesive layer include, in parts by weight, 50 parts of acrylic acid monomers, 10 parts of accelerators, triggering 2 parts of agent, 40 parts of diluent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com