A kind of high thermal conductivity and high strength particle reinforced cast aluminum alloy and its preparation method

A technology of casting aluminum alloy and particle reinforcement, which is used in chemical instruments and methods, mixers, transportation and packaging, etc., can solve the problems of uniform dispersion and low strength of high thermal conductivity aluminum alloys, reduce physical and chemical reactions at the interface, and is conducive to long-term Good service and interface combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

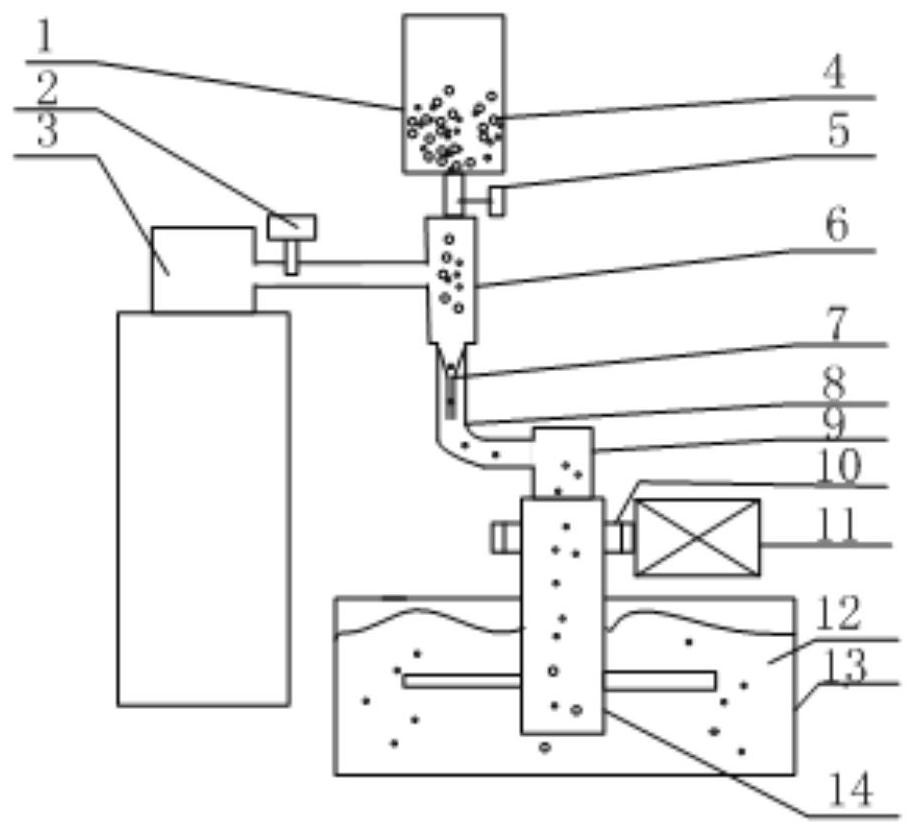

Image

Examples

Embodiment 1

[0034] A preparation method of high thermal conductivity and high strength particle reinforced cast aluminum alloy:

[0035] Step 1: Preparation of high-entropy alloy powder

[0036] First of all, AlCoCrFe, AlCoCrFeNi series high-entropy alloy particles are selected as the reinforcing phase, and the ratio of each component is 1:1. According to the molar atomic ratio and mass fraction of each element, the mass of each component is calculated respectively, and then loaded into a stainless steel ball mill after weighing. In the process, the process control agent is absolute ethanol, vacuumed, filled with argon, and then mechanically alloyed on a planetary ball mill jar for 60h, the ball-to-material ratio is 8:1, and the rotational speed is 250r / min, the preparation gives a high-entropy alloy Powder, the particle size is 1-20μm after sieving.

[0037] Step 2: Weigh the high-entropy alloy powder prepared in step 1, the mass fraction is 3%, and the composition range of the high the...

Embodiment 2

[0041] A preparation method of high thermal conductivity and high strength particle reinforced cast aluminum alloy:

[0042] Step 1: Preparation of high-entropy alloy powder

[0043] First, AlSiTiNi, AlSiTiCrCu series high-entropy alloy particles are selected as the reinforcing phase, and the cost ratio of each element is 1:1. According to the molar atomic ratio and mass fraction of each element, the mass of each component is calculated respectively, and then weighed and put into a stainless steel ball mill jar In the process, the process control agent is absolute ethanol, vacuumed, filled with argon, and then mechanically alloyed on a planetary ball mill jar for 60h, the ball-to-material ratio is 8:1, and the rotational speed is 250r / min, the preparation gives a high-entropy alloy Powder, the particle size is 1-20μm after sieving.

[0044] Step 2: Weigh the high-entropy alloy powder prepared in step 1, the mass fraction is 6%, and the composition range of the high thermal co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com