Perovskite nanowire and preparation method and application thereof

A nanowire and perovskite technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

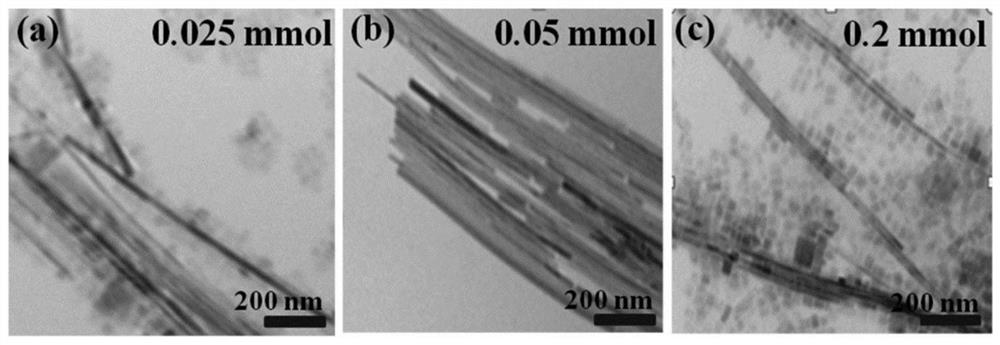

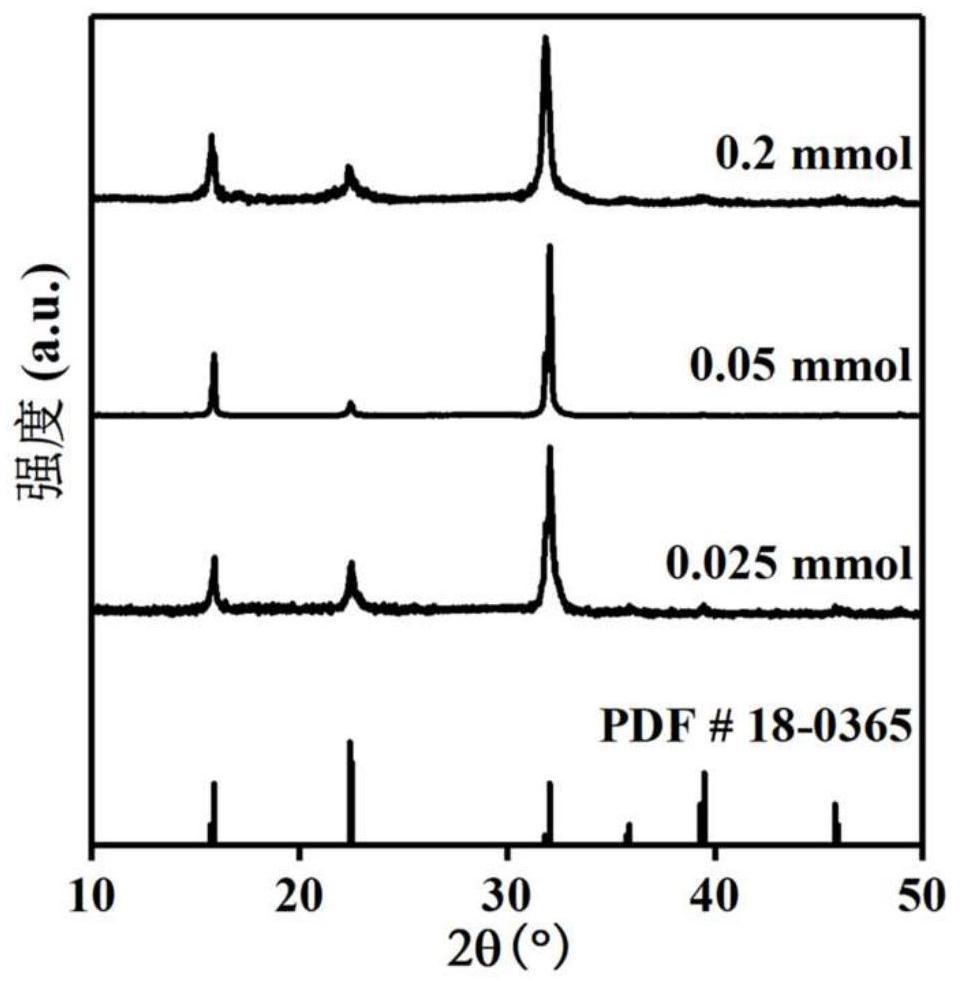

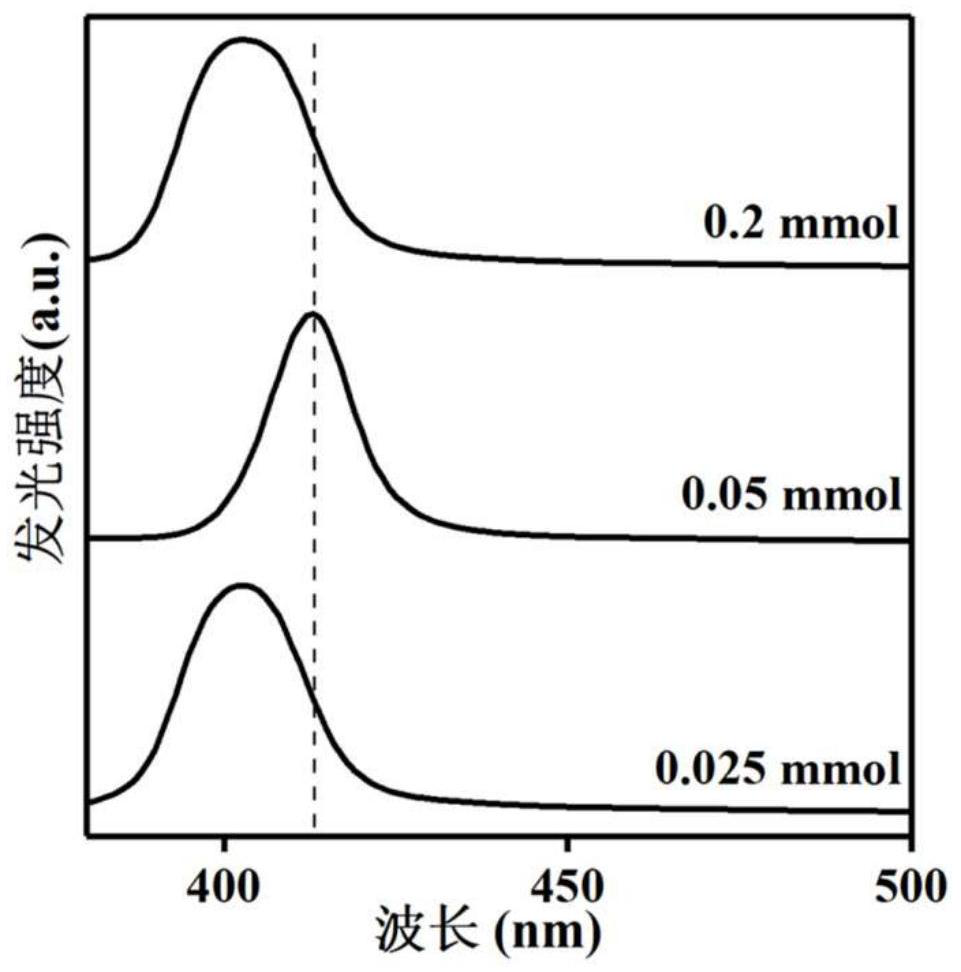

Embodiment 1

[0028] This embodiment provides a kind of preparation method of perovskite nanowire, it comprises the following steps:

[0029] S1, join 10mL octadecene, 1mL oleic acid, 0.4g cesium carbonate in the 50mL three-necked bottle, in N 2 Heating to 120°C under the atmosphere, stirring the solution until it dissolves and turns light yellow, the resulting precursor solution is ready for use in subsequent experiments.

[0030] S2, 0.2mmol lead chloride, 0.5mL oleic acid, 0.025mmol Eu(AcO) 3 Add it to a three-necked flask equipped with 5mL of octadecene and pump it for 30mins, then feed it with N 2 , when heated to 130°C, add 0.4mL octanoic acid, 0.5mL octylamine and 0.8mL oleylamine, and stir for 30mins to obtain a clear transparent solution.

[0031] S3. Heat up to 140°C, inject 0.7mL of precursor into 6.3mL of transparent solution, and keep it at 140°C for 50 minutes, then quickly cool to room temperature with an ice-water bath, and then centrifugally disperse at a speed of 8000rad...

Embodiment 2

[0033] Adopt the same process of embodiment 1, the difference is that the Eu(AcO) in the step 2 of embodiment 1 3 The amount was changed to 0.05mmol, and other conditions remained the same.

Embodiment 3

[0035] Adopt the same process of embodiment 1, the difference is that the Eu(AcO) in the step 2 of embodiment 1 3 The amount was changed to 0.2mmol, and other conditions remained the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com