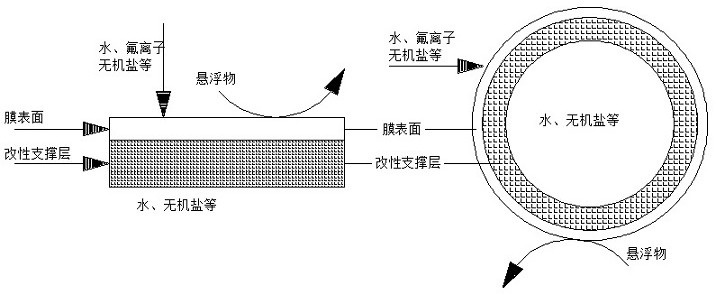

Membrane adsorption deep defluorination treatment system and method

A membrane adsorption and fluorine treatment technology, applied in the fields of adsorption water/sewage treatment, special treatment targets, water/sewage treatment, etc. Adsorption efficiency and regeneration efficiency, increasing effective contact, and the effect of flexible application forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

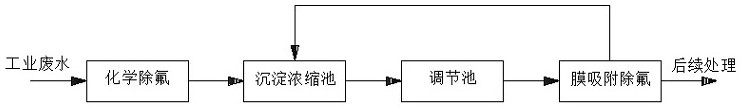

[0031] The fluoride ion content of an industrial wastewater is 10mg / L, and the pH is 11. The wastewater is treated by the following method:

[0032] The waste water is treated by using a membrane adsorption module, the membrane material is polyvinylidene fluoride, the membrane pore size is 0.05 μm, and the inner support layer of the membrane adsorption module is modified with activated alumina through thermal fixation. After the fluorine-containing wastewater is adjusted to pH 7, it enters the membrane adsorption module through the pressure lift pump for filtration and adsorption. The membrane flux is controlled to 130L / ㎡h. After membrane filtration, the concentrated water is returned to the sludge concentration tank. The membrane adsorption module is used for the first time. The fluoride ion content of the product water is 0.5mg / L, and the adsorption capacity is 2.6mg / g.

[0033] When the adsorption of the membrane adsorption module is saturated, use 1.5% sodium hydroxide sol...

Embodiment 2

[0040] The fluoride ion content of reverse osmosis concentrated water in a factory is 5mg / L, and the pH is 6.5. The following methods are used to treat the wastewater:

[0041] The waste water is treated with a membrane adsorption module, the membrane material is polyvinylidene fluoride, the membrane pore size is 0.01 μm, and the inner support layer of the membrane adsorption module is modified with activated alumina after heat fixing. The fluorine-containing wastewater enters the membrane adsorption module through the pressure lift pump for filtration and adsorption. The membrane flux is controlled at 150L / ㎡h. After membrane filtration, the concentrated water is returned to the sludge concentration tank. The membrane adsorption module is used for the first time. 0.4mg / L, the adsorption capacity is 2.7mg / g.

[0042] When the adsorption of the membrane adsorption module is saturated, use 1.5% sodium hydroxide solution to enter the interior of the membrane module through the regen...

Embodiment 3

[0049] After chemical precipitation of industrial wastewater from a certain factory, the fluoride ion content of the produced water is 45mg / L, and the pH is 6. The wastewater is treated by the following method:

[0050] The waste water is treated by a membrane adsorption module, the membrane material is polyvinylidene fluoride, the membrane pore size is 0.1 μm, and the inner support layer of the membrane adsorption module is modified with activated alumina after heat fixing. After flocculation and sedimentation, the produced water of chemical precipitation enters the membrane adsorption module for filtration and adsorption. The membrane flux is controlled to 70L / ㎡h. The content is 0.6mg / L, and the adsorption capacity is 2.8mg / g.

[0051] When the adsorption of the membrane adsorption module is saturated, use 1.5% sodium hydroxide solution to enter the interior of the membrane module through the regeneration water pump for regeneration, control the flux of the regeneration memb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com