Efficient autotrophic nitrogen removal treatment method for urea wastewater

A technology of autotrophic denitrification and treatment method is applied in the field of high-efficiency autotrophic denitrification treatment of urea wastewater, which can solve the problems of increasing the treatment difficulty and treatment cost of urea wastewater, and achieve stable treatment effect, strong economy and high treatment efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

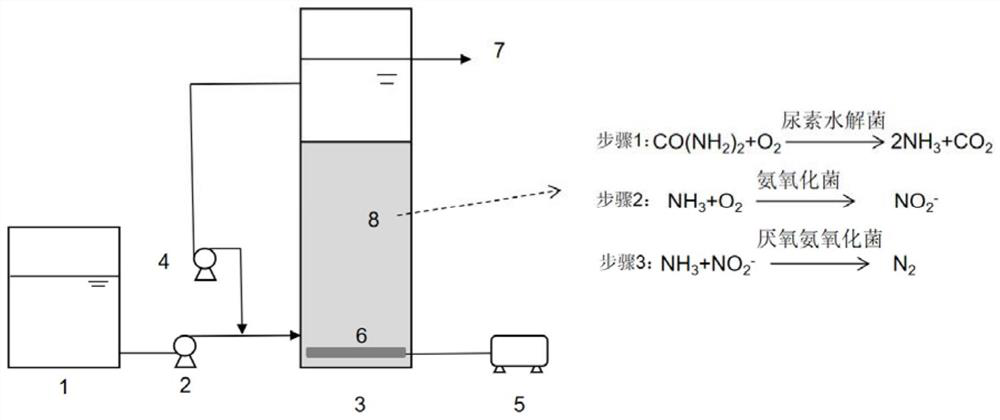

[0034] A high-efficiency autotrophic denitrification treatment method for urea wastewater, comprising the following steps:

[0035] (1) Add 500mL of domesticated and mature anammox sludge (MLSS=2000mg / L) directly into a 1L bioreactor for inoculation, feed 500mL of wastewater with a urea concentration of 400mg / L, turn on aeration and internal circulation, and control The dissolved oxygen concentration was 0.5mg / L, and the reactor was acclimatized and cultivated by stuffy exposure. After 8 hours, the urea removal rate reached 99.2%, the total nitrogen removal rate reached 85.4%, and the reactor acclimatized and cultivated successfully;

[0036] (2) Continuously feed wastewater with a urea concentration of 400mg / L into the reactor successfully cultivated in (1), and control the hydraulic retention time to 5h. At this time, the nitrogen volume load of the influent is about 1.92kgN / m 3 / day, by adjusting the amount of aeration to control the dissolved oxygen concentration in the rea...

Embodiment 2

[0038] A high-efficiency autotrophic denitrification treatment method for urea wastewater, comprising the following steps:

[0039] (1) Add 800mL of domesticated and mature anammox sludge (MLSS=2400mg / L) into a 3L bioreactor for inoculation, feed 500mL of wastewater with a urea concentration of 1500mg / L and 1700mL of tap water, and turn on aeration and internal circulation , control the dissolved oxygen concentration to be 0.5mg / L, carry out stuffy exposure acclimation to the reactor, after 16 hours, the urea removal rate reaches 97.2%, the total nitrogen removal rate reaches 80.4%, and the reactor acclimation is successful;

[0040] (2) Continuously feed wastewater with a urea concentration of 1500mg / L into the reactor successfully cultivated in (1), control the hydraulic retention time to 16h, and control the dissolved oxygen concentration in the reactor to 1.0-1.5mg by adjusting the aeration rate / L, it can be found that the concentration of urea and total nitrogen in the t...

Embodiment 3

[0042] A high-efficiency autotrophic denitrification treatment method for urea wastewater, comprising the following steps:

[0043] (1) Pour 350mL of the mixture of domesticated and mature anammox sludge (MLSS=3500mg / L) into a 2L bioreactor for inoculation, feed 250mL of wastewater with a urea concentration of 4000mg / L and 1400mL of tap water, and turn on the aeration With the internal circulation, the dissolved oxygen concentration is controlled at 0.8 mg / L, and the reactor is acclimated and cultivated with stuffy exposure. After 24 hours, the urea removal rate reaches 96.9%, the total nitrogen removal rate reaches 77.4%, and the reactor is acclimated and cultivated successfully;

[0044] (2) Continuously feed wastewater with a urea concentration of 4000mg / L into the reactor successfully cultivated in (1), control the hydraulic retention time to 24h, and control the dissolved oxygen concentration in the reactor to 2.5-3.0mg by adjusting the aeration rate / L, it can be found t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com