Method for preparing calcium chloride from saponification residues obtained by preparing epoxypropane or epoxy chloropropane through chlorohydrin method and device for realizing method

A technology of epichlorohydrin and propylene oxide, applied in the direction of calcium/strontium/barium chloride, calcium/strontium/barium halide, etc., can solve the problem of limited use, difficult handling, corrosion of steel bars and other metal materials, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

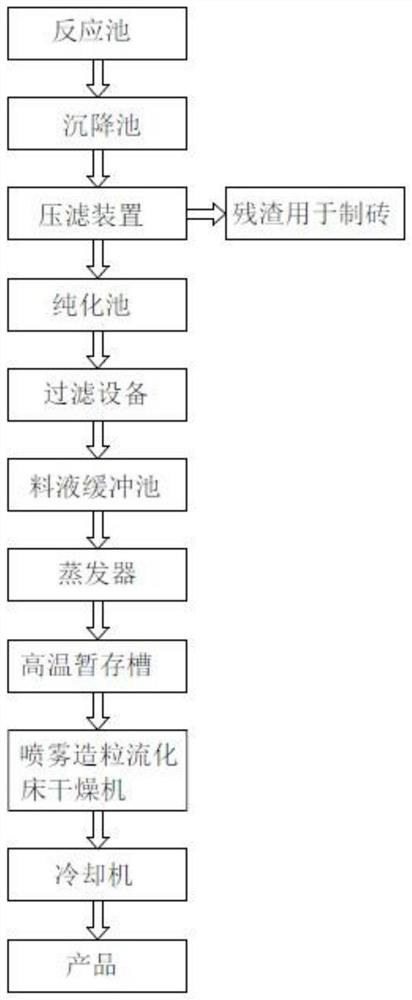

[0059] The saponification residue obtained by preparing propylene oxide by the chlorohydrin method was added to a neutralization reactor filled with hydrochloric acid by-produced in the production of propylene chloride with a concentration of 31wt%, and reacted until the pH of the solution reached 6, and the reaction was basically completed.

[0060] The prepared crude calcium chloride solution enters the settling tank, and the large solid impurities are removed through the settling tank, and then the crude calcium chloride solution is sent to the filter press device for press filtration, and the residue is used for brick making after washing, and the clear liquid Enter the purification pool, the detection COD is about 1500mg / l.

[0061] Add calcium hypochlorite 2.7kg / m with 30% available chlorine to the clear liquid in the purification pool according to the ratio of 0.54 times the COD value to the available chlorine ratio of the purifying agent 3 , react at 100°C for 2 hours,...

Embodiment 2

[0064] Adopt the method identical with embodiment 1, difference is, add the sodium hypochlorite solution 30kg / m of available chlorine 10% to the supernatant liquid in the purification pool according to the ratio of 2 times of COD value and purifying agent available chlorine ratio 3 , react at 100°C for 2 hours, COD drops to 150mg / l; then adjust to pH = 3, add 10% sodium hypochlorite solution of available chlorine that is 0.25 times the ratio of COD value to purifying agent available chlorine, and add sodium hypochlorite solution to each square of clear liquid for about 0.4kg, stirred and reacted at 45°C for 2.0h, at this time the COD was about 25mg / L, and the pH value was adjusted back to 7.

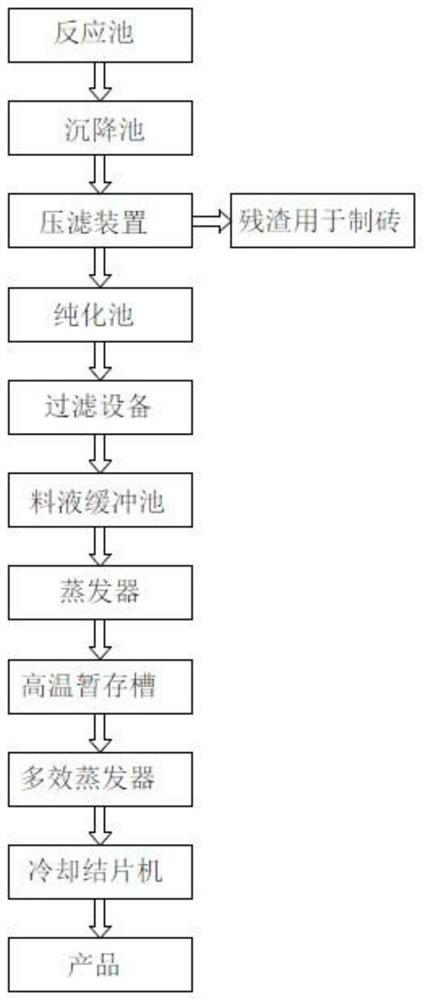

[0065] Then the calcium chloride solution is pumped from the buffer tank to the concentrator, and the concentration of the calcium chloride solution is increased to 50%. The temperature during the concentration is 200°C, and then enters the high-temperature temporary storage tank, and is ...

Embodiment 3

[0067] Using the same method as in Example 1, the difference is that the by-product hydrochloric acid in the production of tetrachlorethylene is used to replace the by-product hydrochloric acid in the production of propylene chloride, and at the same time, after entering the high-temperature temporary storage tank, it is evaporated and concentrated by a multi-effect evaporator to 74wt%, then transported to the cooling flaker for flaking, the product is flaky calcium chloride dihydrate, and the content of calcium chloride is 74wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com