Method for preparing flavanone glycoside compound by using industrial chromatographic technology

A technology of dihydroflavone glycosides and industrial chromatography, which is applied in the field of preparation of dihydroflavone glycosides using industrial chromatography technology, can solve the problems of the prior art that no naringerin rutin monomer compound has been found, and achieve sample stability problem, high purity, good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

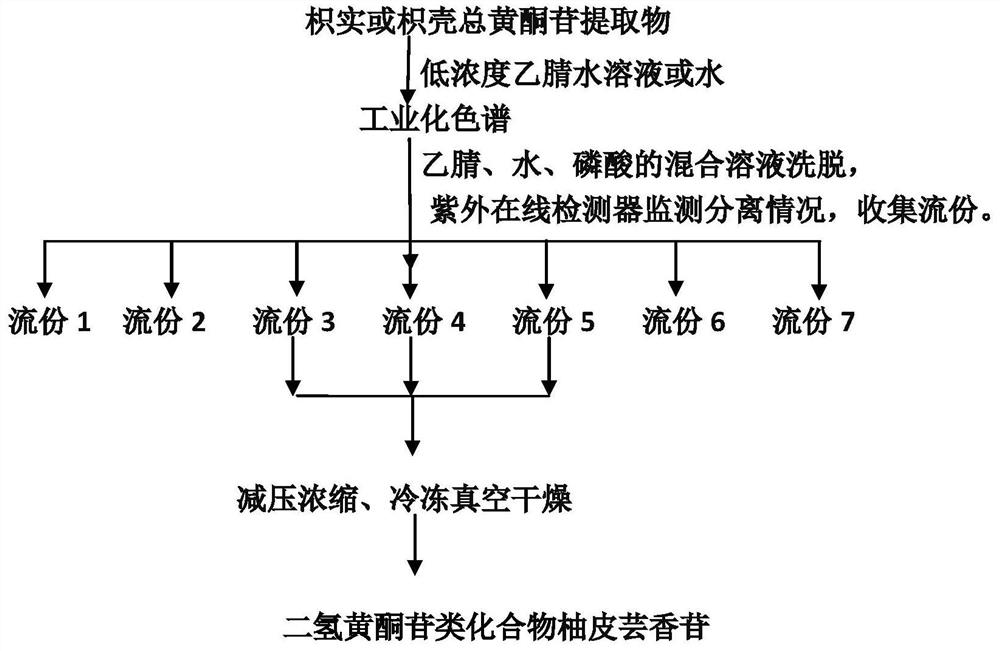

[0027] A kind of method that utilizes industrial chromatographic technology to prepare dihydroflavonoid glycoside compound naringin rutin, process flow chart is as follows figure 1 As shown, the specific steps are as follows:

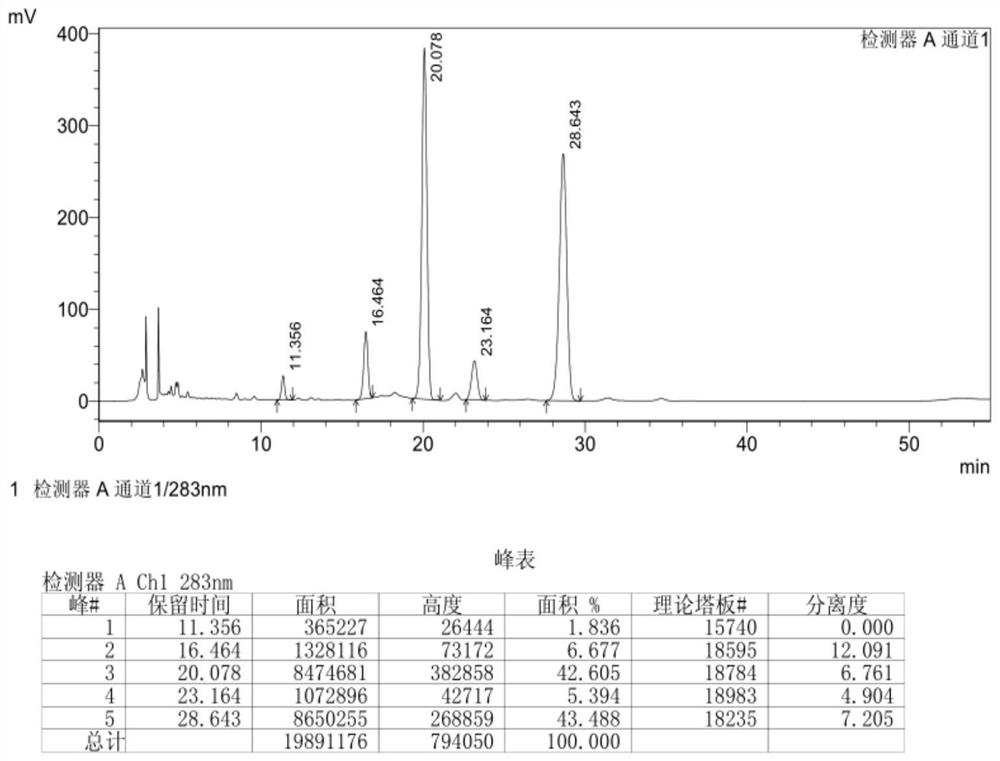

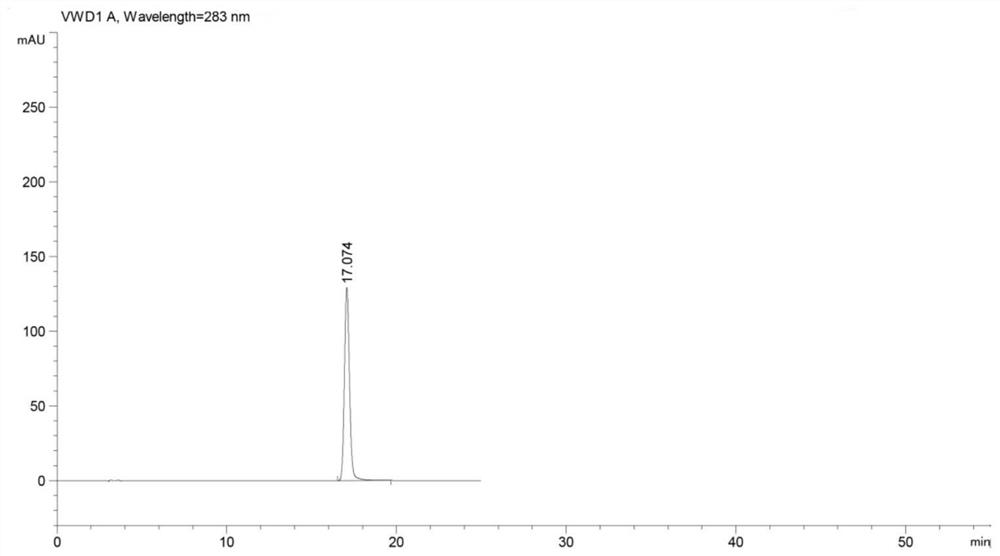

[0028] Get the total flavonoid glycosides extract of Fructus Aurantii (its HPLC chromatogram sees figure 2 ), wherein the naringin rutin content is about 3.5% (W / W), add 4.0% (V / V) acetonitrile aqueous solution to dissolve it and be formulated with a solution of 125mg / ml, filter, and set aside to obtain a sample solution; the sample Solution 90L, injected into the dynamic axial compression column system, the industrial chromatographic filler is UniPSN 40-300 (reverse polymer filler), acetonitrile:water:phosphoric acid solution (15:85:0.1, V / V / V) is the elution reagent, the elution flow rate is 2000mL / min, the ultraviolet detection wavelength is 283nm, and the reference wavelength is 210nm. According to the peak time of naringel rutin components and t...

Embodiment 2

[0030] A kind of method that utilizes industrial chromatographic technology to prepare dihydroflavonoid glycoside compound naringin rutin, process flow chart is as follows figure 1 As shown, the specific steps are as follows:

[0031] Get the total flavonoid glycoside extract of Fructus Aurantii, wherein the naringin rutin content is about 2.5% (W / W), add 3.0% (V / V) acetonitrile aqueous solution to dissolve it and prepare a solution of 85 mg / ml, filter to obtain Sample solution: inject 115L of sample solution into the dynamic axial compression column system, the industrial chromatographic filler is UniPS 40-300 (reverse polymer filler), acetonitrile: water: phosphoric acid solution (25:75:0.1, V / V / V) is the eluent, the elution flow rate is 1500mL / min, the ultraviolet detection wavelength is 283nm, and the reference wavelength is 210nm. According to the peak time of naringel rutin components and the height of the chromatographic peak, the eluent of the prepared naringelin rut...

Embodiment 3

[0033] A kind of method that utilizes industrial chromatographic technology to prepare dihydroflavonoid glycoside compound naringin rutin, process flow chart is as follows figure 1 As shown, the specific steps are as follows:

[0034] Get the total flavonoid glycoside extract of Fructus Aurantii, wherein the naringin rutin content is about 2.0% (W / W), add water to dissolve it and prepare a 100mg / ml solution, filter to obtain a sample solution; sample solution 100L, Inject into the dynamic axial compression column system, the industrial chromatographic filler is or CG161M (reversed-phase polymer filler), acetonitrile:water:phosphoric acid solution (18:82:0.1, V / V / V) is the eluent, and the elution flow rate is It is 1750mL / min, the ultraviolet detection wavelength is 283nn, and the reference wavelength is 210nm. According to the peak time of naringel rutin components and the height of the chromatographic peak, the eluent of the prepared naringelin rutin was collected, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com