Cellulose nanofibril suspension and preparation method thereof

A technology of nanofibrils and cellulose, which is applied in the direction of cellulose pulp post-treatment, fiber raw material treatment, washing/replacing pulp treatment liquid, etc., which can solve the limitation of nano-cellulose application, has not been widely used, and the processing process is complicated, etc. problems, to achieve the effect of improving oxidation performance, green and environmental protection in the preparation process, and uniform diameter distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

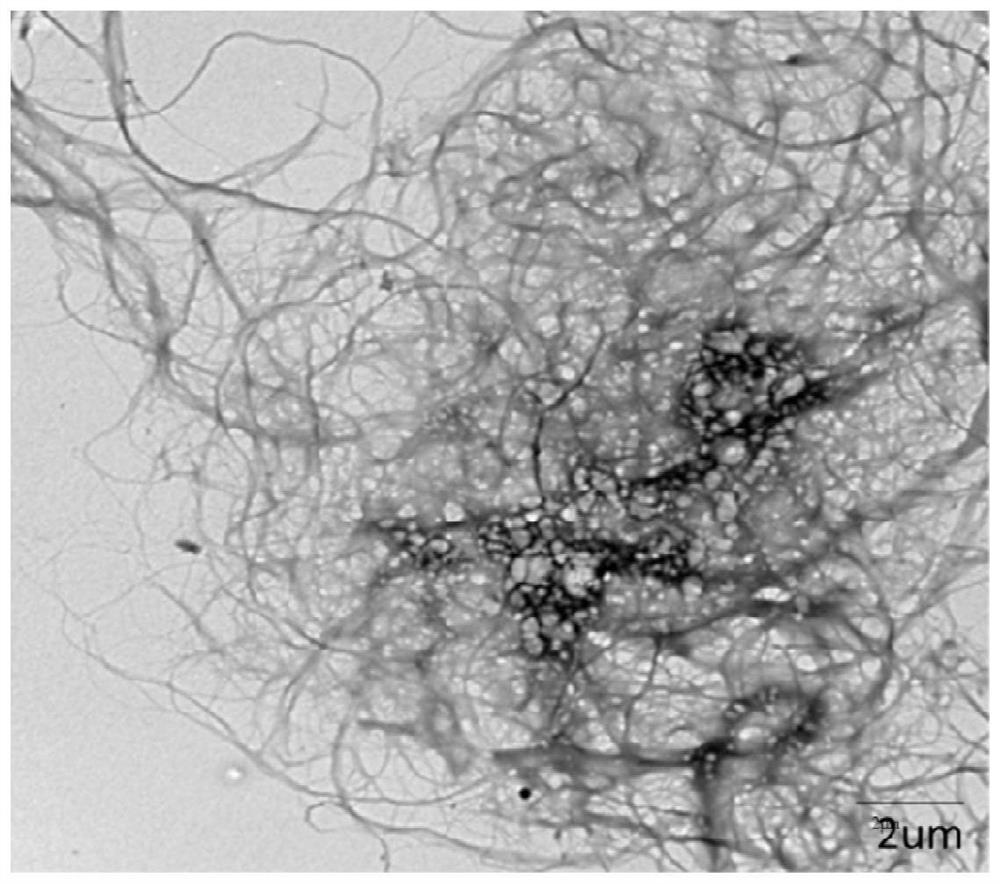

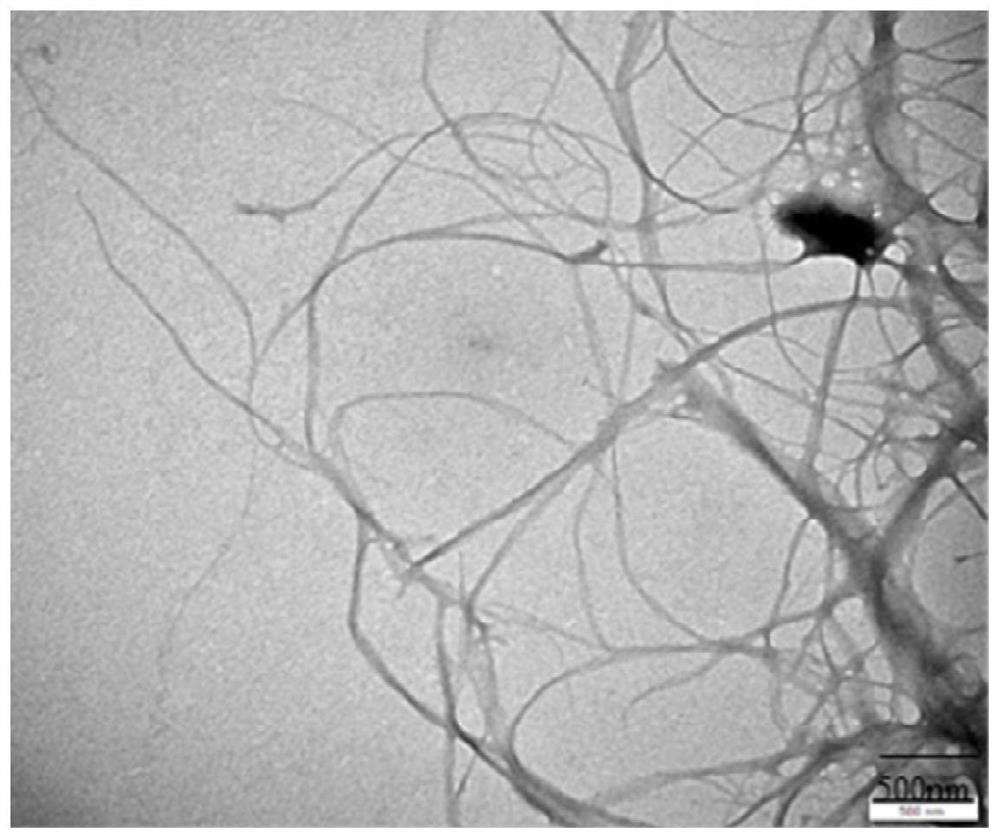

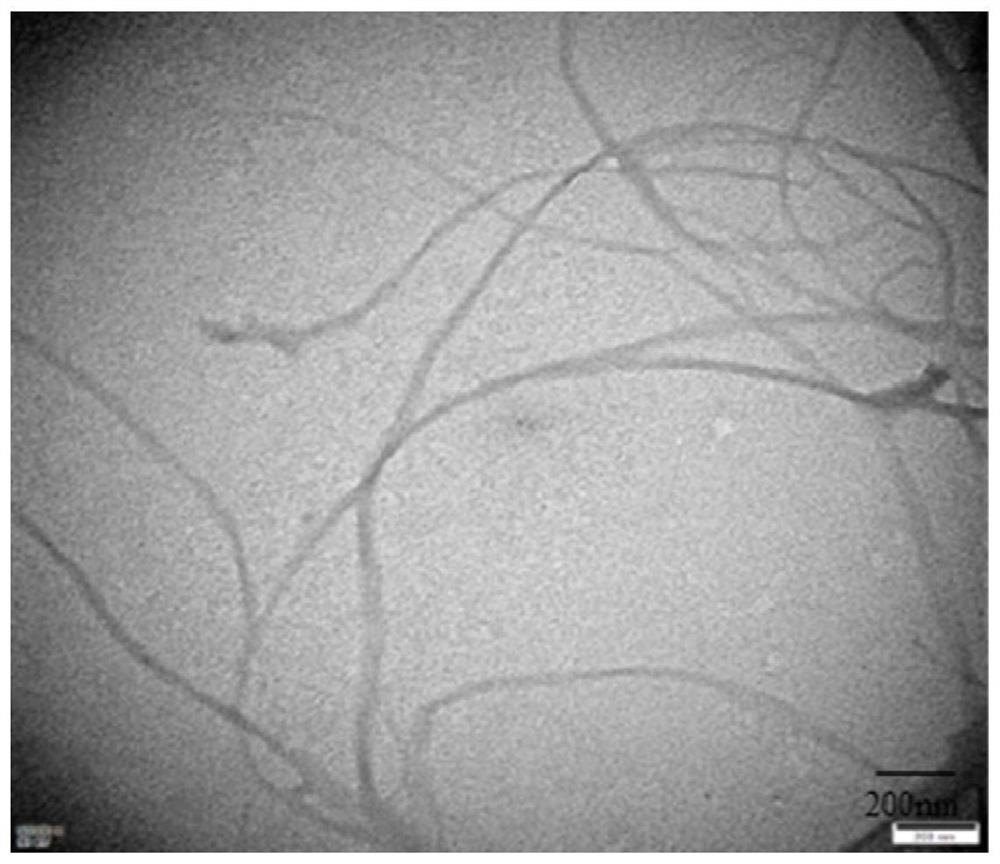

[0032] The preparation method of a cellulose nanofibril suspension in the present invention comprises putting the wood fiber of 30-40 ° SR in a three-necked flask, and undergoing a polar solvent swelling treatment for 2-4 hours under the condition of an ultrasonic bath at 48-55 °C , and then sequentially add a certain proportion of oxalic acid, sulfuric acid with a volume fraction of 1%, and potassium permanganate for oxidation treatment for 4-6 hours, use hydrogen peroxide to terminate the reaction, and wash the obtained mixed system for 10-30 minutes. Centrifugal treatment, separation The upper liquid, the cellulose nanofibrils suspension with a length of 1-10um and a diameter of 20-60nm in the finally obtained cellulose nanofibril suspension.

[0033] Oxalic acid plays a complex role in the potassium permanganate oxidation system. Under acidic conditions, permanganate ions are oxidized into trivalent manganese ions, but the trivalent manganese ions are not stable, and oxalat...

Embodiment 1

[0038] Take 1g (absolutely dry) coniferous wood fibers with a beating degree of 30°SR in a 500mL three-necked flask, slowly add 45mL of acetone, and seal the flask mouth with a plastic wrap to prevent heat loss and solvent volatilization. The magnetic stirrer is set at 500r / min, put the system in an ultrasonic constant temperature water bath at 50°C, and treat it for 120 min to make the fibers evenly dispersed. Add 2.5g oxalic acid, 100mL sulfuric acid with a volume fraction of 1%, and slowly add potassium permanganate. After adding 1.5g, the system becomes a purple viscous liquid; react for 4 hours, add 4mL hydrogen peroxide dropwise to the system, and the color of the system gradually changes White. Divide the cooled viscous liquid into six equal parts and put them into centrifuge tubes, set the centrifugal speed to 5800r / min, and the centrifugation time to 10min, wash with deionized water 4 times until the supernatant is cloudy, and obtain a length of 8-10μm and a diameter...

Embodiment 2

[0041] Take 1g (absolutely dry) coniferous wood fiber with a beating degree of 35°SR in a 500mL three-necked flask, slowly add 45mL of DMF, seal the flask with plastic wrap, set the magnetic stirrer at 500r / min, and place the system at 50°C In the ultrasonic constant temperature water bath, treat for 120min to make the fibers disperse evenly. Add 2.5g of oxalic acid, 100mL of sulfuric acid with a volume fraction of 1%, and slowly add potassium permanganate. After adding 1.403g, the system becomes a brown viscous liquid; react for 4 hours, add 1.5mL of hydrogen peroxide dropwise to the system, and the system gradually becomes for white. Divide the cooled viscous liquid into six equal parts and put them into centrifuge tubes, set the centrifugal speed to 5800r / min, and the centrifugation time to 10min, wash with deionized water for 5 times until the supernatant becomes turbid, and obtain a tube with a length of 4-6μm and a diameter of 30-40 nm nanofibril suspension.

[0042] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com