VO2@SiO2 nano particle filling type electro-induced phase change composite material and preparation method thereof

A technology of phase-change composite materials and nanoparticles, which is applied in the field of VO2@SiO2 nanoparticle-filled electro-phase-change composite materials and manufacturing methods, and can solve the problems of unknown influence on electro-phase-change performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] VO 2 @SiO 2 The preparation method of the nanoparticle-filled electrophase-change composite material comprises the following steps:

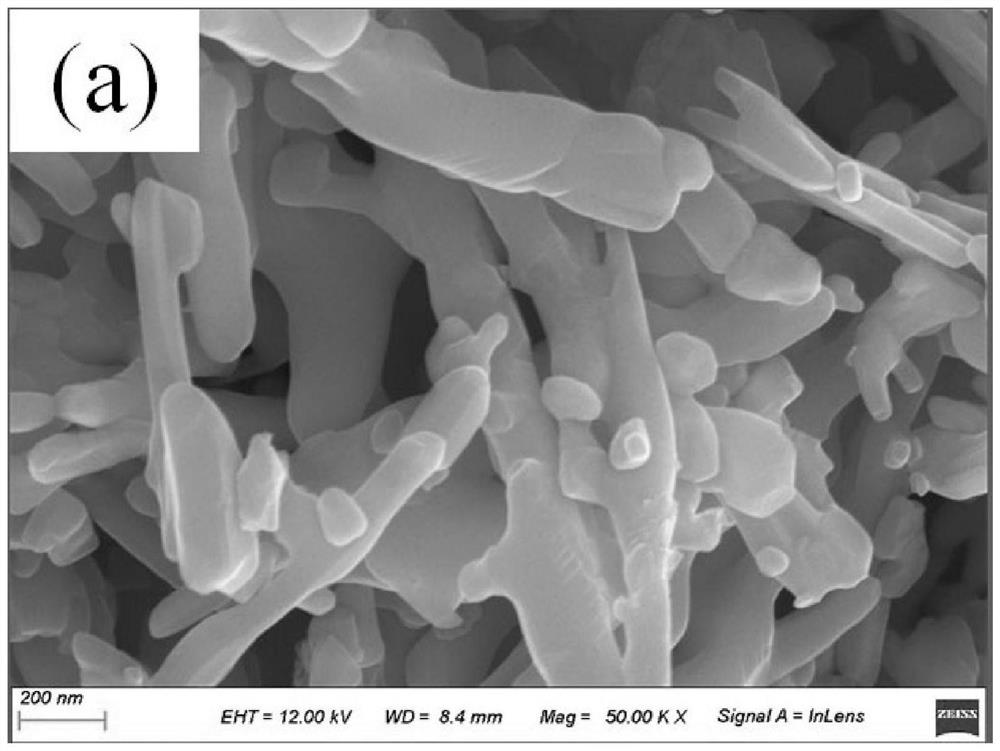

[0046] VO 2 (M) Synthesis of nanoparticles:

[0047] First, 1 part of oxalic acid is dispersed in 10 parts of deionized water, and then 0.5 part of vanadium pentoxide is added to the above mixed solution, and after fully stirring and mixing, a yellow solution is obtained.

[0048] Transfer the yellow solution to a 200ml polytetrafluoroethylene-lined stainless steel autoclave, and keep the temperature at 180°C-240°C for 4h-48h. After the constant temperature is finished, cool down to room temperature naturally, wash and filter with absolute ethanol and deionized water respectively, and freeze-dry for 12 hours to obtain blue powder VO 2 (B).

[0049] will get VO 2 (B) The sample is vacuum annealed at 500°C-650°C for 30-90mins in a tube furnace to obtain M-phase VO 2 nanoparticles.

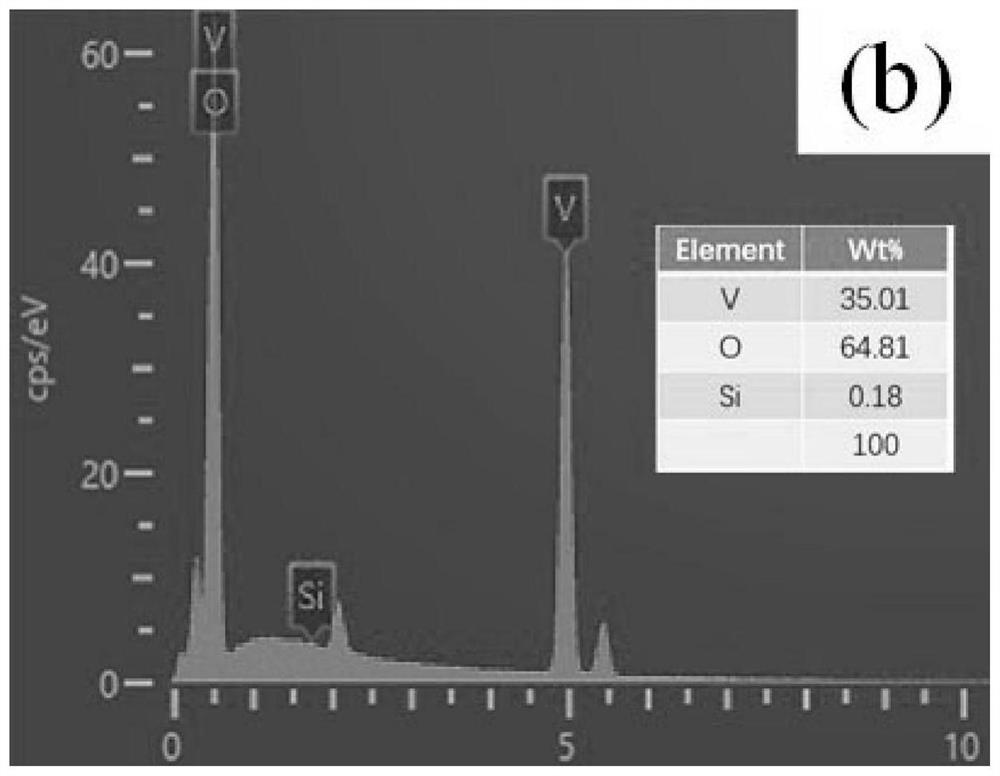

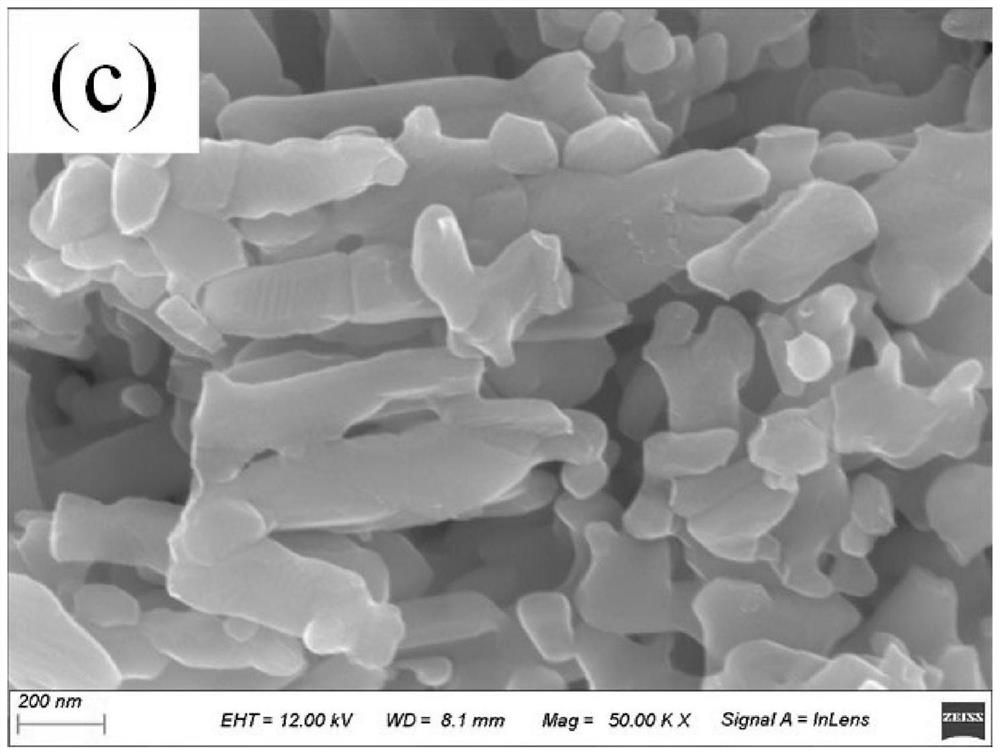

[0050] VO 2 @SiO 2 Synthesis of nanoparticles: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com