Poly(4-methyl-1-pentene) hollow fiber membrane applied to ECMO, and preparation method thereof

A fiber membrane and pentene technology, which is applied in the field of poly-4-methyl-1-pentene hollow fiber membrane and its preparation, can solve the problems of complex production process, difficult regulation of pore size, and many control conditions, etc. The effect of good continuity, uniform distribution of surface pore structure, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

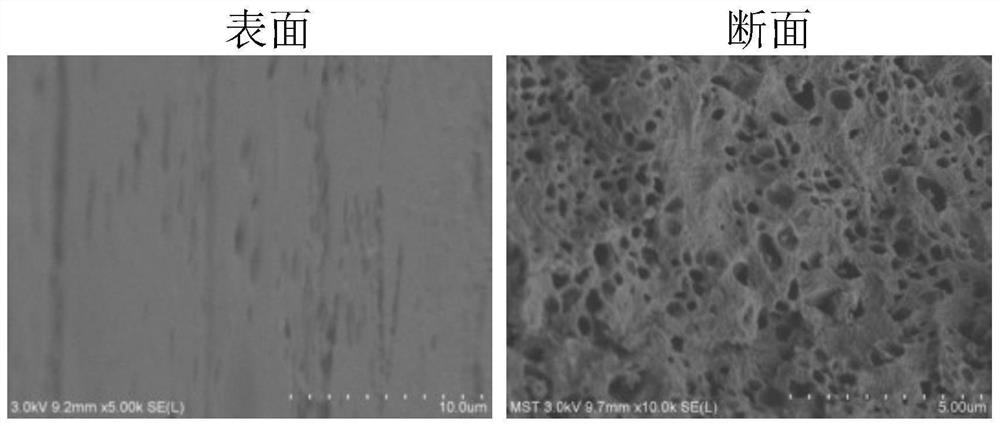

[0057] In the preparation method of the present invention, preferably adopt binary diluent, wherein a kind of diluent is better with the compatibility of poly-4-methyl-1-pentene, such as dioctyl phthalate; And another A diluent has poor compatibility with poly-4-methyl-1-pentene, for example: dibutyl sebacate, triethyl phosphate, triethyl citrate, etc. The one-component diluent and PMP have good solubility, high interaction force, narrow phase separation area, and easy S-L phase separation to form lace-like or crystalline structures. If the second diluent with poor compatibility is used, the cloud point curve will move up, the phase separation region will become wider, and L-L phase separation will easily occur, forming a honeycomb or continuous pore structure, and the permeation flux will increase.

[0058] The purpose of the additive can enhance the overall viscosity of the casting solution, and the uniformity of the hollow fiber obtained by the casting solution system throu...

Embodiment 1

[0087] For the preparation of polymer base film by thermal phase separation method, the content and treatment method of each material in the film forming system are as follows, the polymer is poly-4-methyl-1-pentene (PMP), which is produced by Mitsui Chemicals, Japan, and the commodity type It is TPX, the mass content is 50%, and the thinner adopts dioctyl phthalate with good compatibility with TPX as the single diluent, and the mass content is 40%, and the porogen PEG-400 is used as the additive, and the mass content is 10% %.

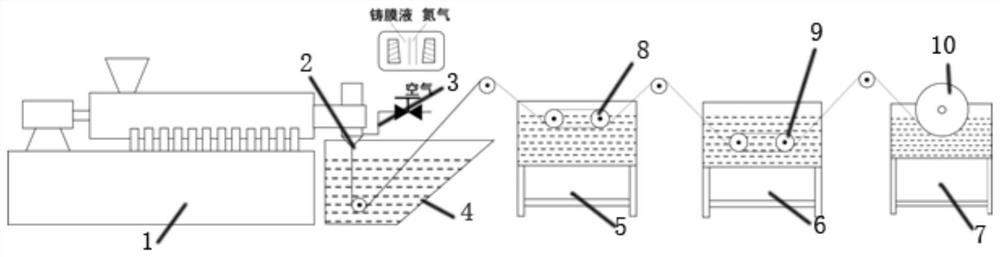

[0088] Put the mixed raw materials into a twin-screw extruder and extrude at a temperature of 250° C.; the residence time of the entire extrusion process is 5 minutes, and the pressure is 5 MPa. Extruded through the spinneret, after passing through the 10cm air section, the temperature is lowered in the quenching bath to cause phase separation, and after cooling, it is rapidly solidified to form a film, and then stretched by the godet wheel and then e...

Embodiment 2

[0091] For the preparation of polymer base film by thermal phase separation method, the content and treatment method of each material in the film forming system are as follows, the polymer is poly-4-methyl-1-pentene (PMP), which is produced by Mitsui Chemicals, Japan, and the commodity type It is TPX, the mass content is 50%. The diluent adopts dioctyl phthalate with good compatibility with TPX and dibutyl phthalate with poor compatibility with TPX as binary diluent, and phthalic acid The mass content of dioctyl ester is 15%, the mass content of dibutyl phthalate is 25%, and the porogen PEG-400 is used as an additive, and the mass fraction is 10%.

[0092] Put the mixed raw materials into a twin-screw extruder and extrude at a temperature of 250° C.; the residence time of the entire extrusion process is 5 minutes, and the pressure is 5 MPa. Extruded through the spinneret, after passing through the 10cm air section, the temperature is lowered in the quenching bath to cause phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com