Concrete aggregate dispersing agent

A dispersant and concrete technology, applied in the field of concrete adjuvants, can solve the problems of reducing concrete strength and durability, unfavorable concrete transportation, and increasing engineering costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

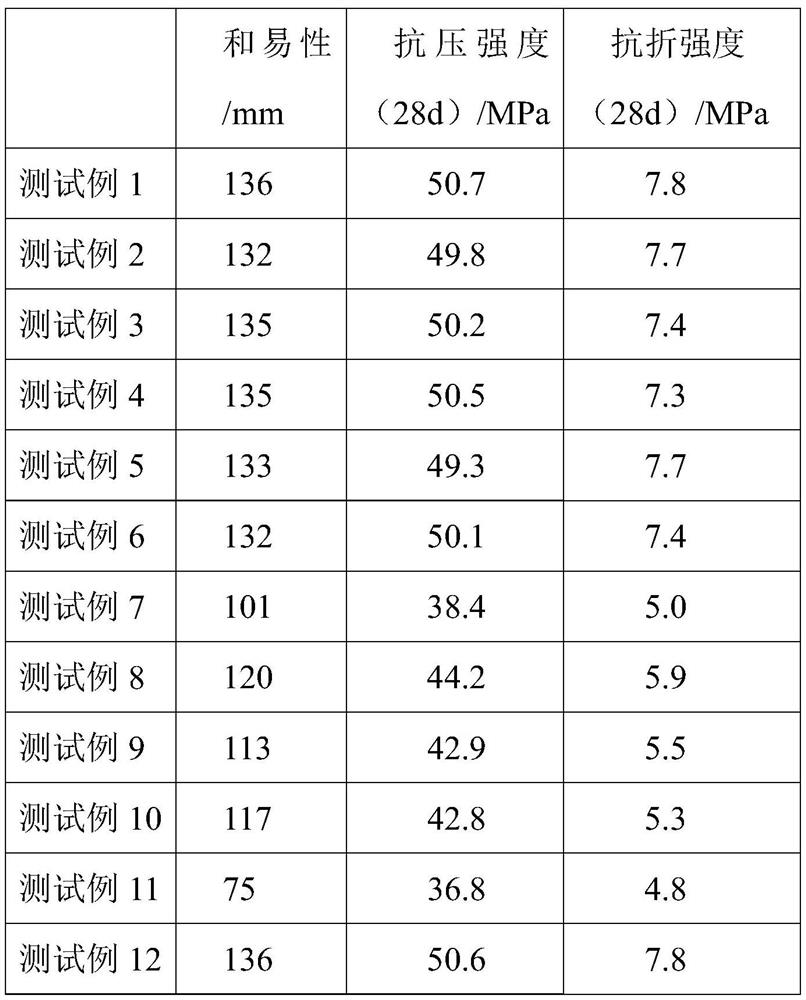

Examples

Embodiment 1

[0029] A concrete aggregate dispersant is composed of maleic anhydride-pentaerythritol copolymer, sodium polyacrylate microspheres and octylphenol polyoxyethylene ether in a mass ratio of 10:1.2:1.

[0030] Wherein, the preparation method of maleic anhydride-pentaerythritol polymer is as follows:

[0031] Dry maleic anhydride and pentaerythritol in an oven at normal pressure at 40°C, put the dried maleic anhydride and pentaerythritol into the reactor at a mass ratio of 5.6:1, raise the temperature to 180°C, and cool down after 5 hours of reaction Add concentrated sulfuric acid and concentrated phosphoric acid at a mass ratio of 5.6:1 to 50°C to add mixed acid, the amount of mixed acid is 1% of the total mass of maleic anhydride and pentaerythritol after drying, stir at high speed for 30 minutes, adjust the pH of the system to 7 with ammonia water, Return to room temperature.

[0032] The preparation method of sodium polyacrylate microspheres is as follows:

[0033] Add sodiu...

Embodiment 2

[0035] A concrete aggregate dispersant, which is composed of maleic anhydride-pentaerythritol copolymer, sodium polyacrylate microspheres, and octylphenol polyoxyethylene ether in a mass ratio of 10:1:1.

[0036] Wherein, the preparation method of maleic anhydride-pentaerythritol polymer is as follows:

[0037] Dry maleic anhydride and pentaerythritol in an oven at normal pressure at 40°C, put the dried maleic anhydride and pentaerythritol into the reactor at a mass ratio of 3:1, raise the temperature to 200°C, and cool down after 4 hours of reaction Add concentrated sulfuric acid and concentrated phosphoric acid at a mass ratio of 3:1 to 55°C to add mixed acid, the amount of mixed acid is 1% of the total mass of maleic anhydride and pentaerythritol after drying, stir at high speed for 40 minutes and adjust the pH of the system to 7 with ammonia water, Return to room temperature.

[0038] The preparation method of sodium polyacrylate microspheres is as follows:

[0039] Add ...

Embodiment 3

[0041] A concrete aggregate dispersant, which is composed of maleic anhydride-pentaerythritol copolymer, sodium polyacrylate microspheres, and octylphenol polyoxyethylene ether in a mass ratio of 8:1:1.

[0042] Wherein, the preparation method of maleic anhydride-pentaerythritol polymer is as follows:

[0043] Dry maleic anhydride and pentaerythritol in an oven at normal pressure at 40°C, put the dried maleic anhydride and pentaerythritol into the reactor at a mass ratio of 5:1, raise the temperature to 200°C, and cool down after 5 hours of reaction Add concentrated sulfuric acid and concentrated phosphoric acid at a mass ratio of 5:1 to 55°C to add mixed acid, the amount of mixed acid is 1% of the total mass of maleic anhydride and pentaerythritol after drying, stir at high speed for 50 minutes and adjust the pH of the system to 7 with ammonia water, Return to room temperature.

[0044] The preparation method of sodium polyacrylate microspheres is as follows:

[0045]Add so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com