Liquid fuel additive, liquid fuel as well as preparation method and application of liquid fuel additive

A liquid fuel and additive technology, applied in the field of liquid fuel and its preparation, and liquid fuel additive, can solve the problems of poor product performance, complex process, high cost of raw materials, and achieve good fluidity, wide sources and good thermal stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

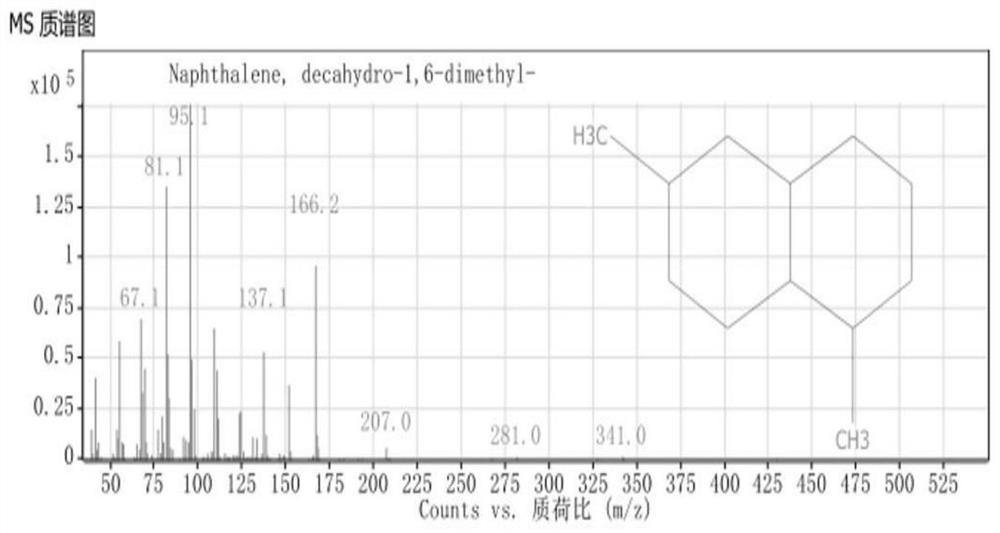

[0069] Example 1 A kind of method that uses abietic acid as raw material to prepare fuel additive

[0070] (1) Catalytic hydrogenation reaction: Weigh 1 g of abietic acid raw material and add it to a tank reactor, add 10 ml of n-hexane as a solvent, weigh 0.5 g of 5% Pd / C catalyst, put it into the reactor, and install the tank after adding materials Type reactor to ensure airtightness, feed hydrogen, pressurize the reaction system to 4Mpa, and complete the ventilation and pressurization. Set the reaction conditions, react at 295°C for 240 minutes, and obtain the hydrogenated product;

[0071] Among them, the raw material of rosin acid is obtained by separating crude tall oil from industrial waste oil.

[0072] (2) Catalytic cracking reaction: Add 0.8g hydrogenation product and 0.2g HY catalyst (obtained by ammonia exchange treatment of Y molecular sieve) into the kettle reactor, add 5ml of n-hexane as solvent, and feed 3Mpa H 2 , reacted at 300° C. for 120 min, and the pro...

Embodiment 2

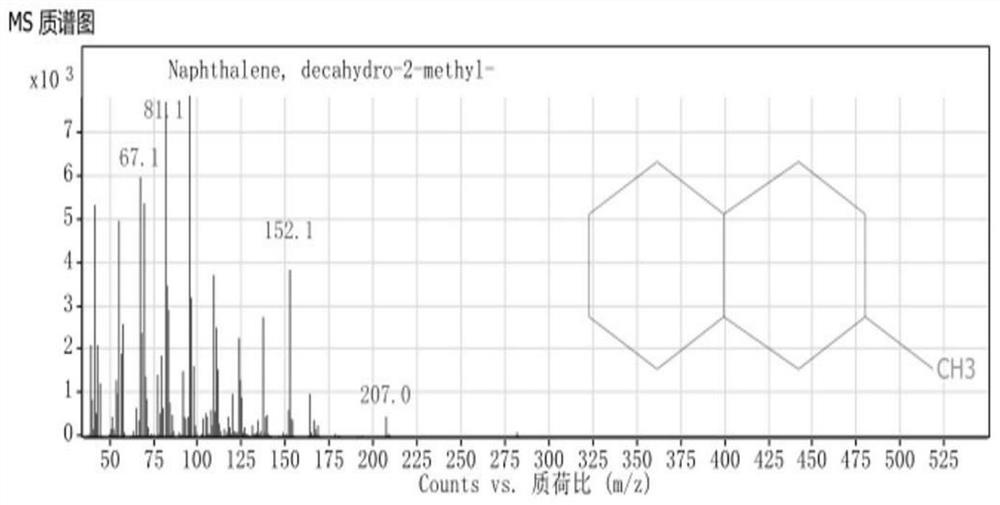

[0073] Example 2 A kind of method that takes pimaric acid as raw material to prepare fuel additive

[0074] (1) Catalytic hydrogenation reaction: Weigh 5 g of pimaric acid raw material and add it to a kettle reactor, add 20 ml of n-hexane as a solvent, weigh 2.5 g of 5% Pd / C catalyst, put it into the reactor, and feed hydrogen to the reaction Pressurize the system to 4Mpa, react at 330°C for 240min;

[0075] (2) Catalytic cracking reaction: 4g of hydrogenation product and 1g of HY catalyst were added to the tank reactor, 15ml of n-hexane was added as solvent, and 4Mpa H 2 , reacted at 300°C for 150 min, and the product was analyzed by GC-MS after the reaction, and the final target component content was 70%.

Embodiment 3

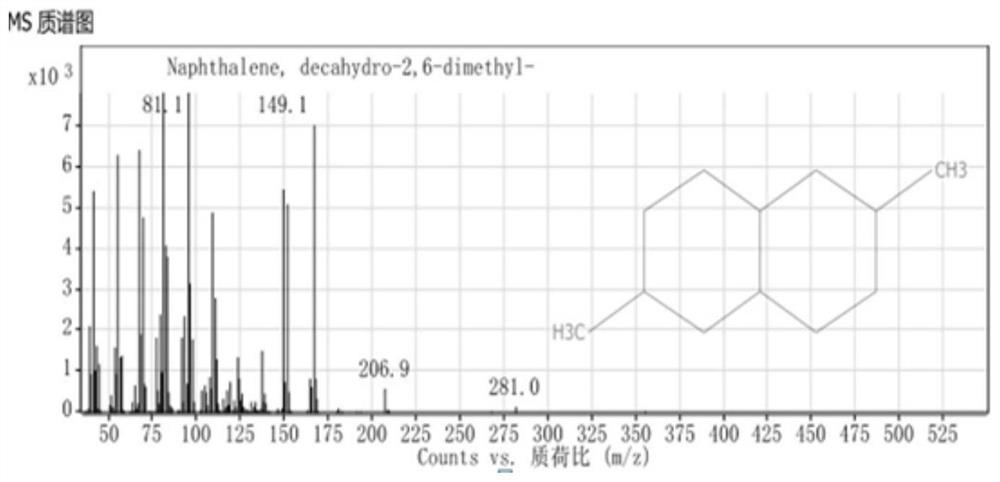

[0076] Example 3 A kind of method that uses dehydroabietic acid as raw material to prepare fuel additive

[0077] (1) Catalytic cracking reaction: 0.5g dehydroabietic acid and 0.5g HY are added to the tank reactor, measure 10ml of n-hexane and pour it into N 2 2Mpa, set the reaction temperature to 300°C, adjust the rotation speed to 500rpm, and continue the reaction for 120min. After the reaction is over, take out the product;

[0078] (2) Catalytic hydrogenation reaction: react 0.4g cracked product with 0.25g hydrogenation catalyst 5%Pd / C in a reactor, add 5ml n-hexane, use hydrogen to pressurize the reaction system to 4Mpa, control the reaction temperature The experiment was carried out at 350°C and the reaction time was 240min. After the reaction, the product was analyzed by GC-MS. The final target component content was 81.6%, and the cracked product was the target component after hydrogenation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com