Glucose-inhibiting type oxygen-resistant hexanoic acid producing bacterium

A technology for glucose inhibition and caproic acid bacteria, which is applied to bacteria, microorganisms, biofuels, etc., can solve the problems of unfavorable industrial cultivation and application of caproic acid bacteria, and achieve the effects of improving wine quality, simple cultivation conditions and strong oxygen resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 Strain screening of glucose-inhibiting oxygen-tolerant caproic acid bacteria of the present invention

[0034] The glucose-inhibiting oxygen-tolerant caproic acid bacteria (Clostridium celerecrescens) of the present invention is isolated from high-quality old pit mud of a certain winery in Hubei, using ES (ethanol sodium acetate) medium: yeast extract 1%, anhydrous sodium acetate 0.5%, MgSO 4 ·7H 2 O 0.02%, K 2 HPO 4 0.04%, (NH 4 ) 2 SO 4 0.05%, after sterilization, add 2% absolute ethanol and 1% calcium carbonate. Take an appropriate amount of pit mud and add it into a test tube with 90% ES medium, place it in a 35°C incubator and culture it for 7 days, observe the gas production, put the test tube with good gas production in a water bath at 80°C for 10 minutes, Then, 1 mL of the bacterial solution was added into test tubes containing ES medium for enrichment culture, and repeated 4 times. Then use the copper sulfate chromogenic method to qualitative...

Embodiment 2

[0037] Example 2 Verification of the amount of caproic acid produced by the glucose-inhibiting type oxygen-tolerant caproic acid bacteria of the present invention

[0038] Glucose-inhibiting type oxygen-tolerant caproic acid bacteria of the present invention is inoculated in the 100mL stopper test tube that ES substratum is housed with 5% inoculum (ES substratum composition: yeast extract 1%, anhydrous sodium acetate 0.5%, MgSO 4 ·7H 2 O 0.02%, K 2 HPO 4 0.04%, (NH 4 ) 2 SO 4 0.05%, after sterilization, add 2% absolute ethanol and 1% calcium carbonate. ), the liquid content is more than 90%, and then sealed with a parafilm. Incubate at 33°C for 7 days and use as seed solution. Inoculate 5% of the seed solution into a 100mL stoppered test tube filled with culture medium, the filling volume is more than 90%, and then seal it with a parafilm. Cultivate at a constant temperature at 33°C, and start sampling every day from the third day to detect the content of butyric aci...

Embodiment 3

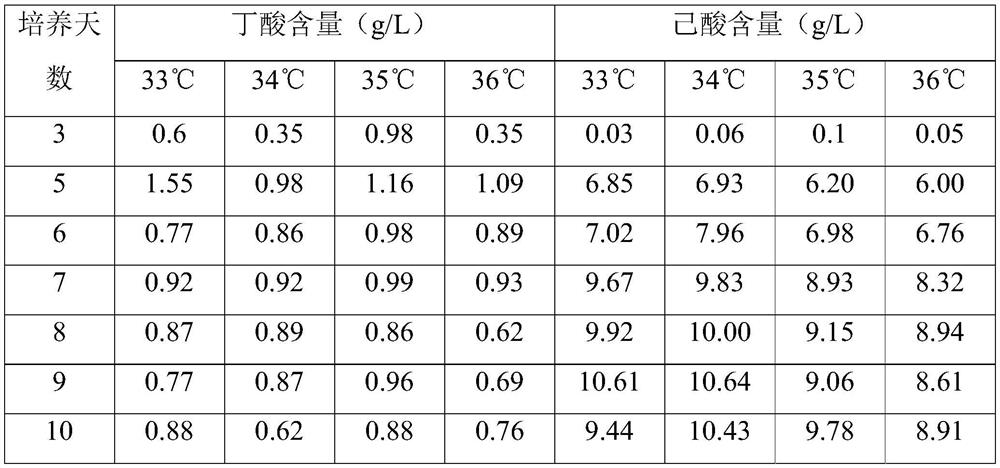

[0043] Example 3 Verifying the Effects of Different Temperatures on the Glucose-inhibiting Oxygen-tolerant Caproic Acid Bacteria of the Present Invention

[0044] Glucose-inhibiting type oxygen-tolerant caproic acid bacteria of the present invention is inoculated in the 100mL stopper test tube that ES substratum is housed with 5% inoculum size (ES substratum composition: yeast extract 1%, anhydrous sodium acetate 0.5%, MgSO 4 ·7H 2 O 0.02%, K 2 HPO 4 0.04%, (NH 4 ) 2 SO 4 0.05%, after sterilization, add 2% absolute ethanol and 1% calcium carbonate. ), the liquid content is more than 90%, and then sealed with a parafilm. Incubate at 33°C for 7 days and use as seed solution. Inoculate 5% of the seed solution into a 100mL stoppered test tube filled with culture medium, the filling volume is more than 90%, and then seal it with a parafilm. Culture at constant temperature at 33°C, 34°C, 35°C, and 36°C, respectively, and take samples during the fermentation process to dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com