Novel ion cleaning technology based on plating of hard alloy surface with ta-C film

A technology of ion cleaning and process, which is applied in metal material coating process, ion implantation plating, sputtering plating, etc., can solve the problems of improving the bonding force of the film base, limiting performance, and damaging the workpiece, so as to improve the deposition thickness and Hardness, improve the bonding force of the film base, and reduce the effect of damage to the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) Ultrasonic 30kHz to clean impurities on the surface of the plasma cemented carbide substrate, and install the furnace;

[0051] (2) Arc-enhanced argon ion bombardment in the vacuum coating equipment to remove impurities on the surface of the cemented carbide substrate;

[0052] (3) Vacuumize the vacuum chamber of the vacuum coating equipment, and the vacuum degree reaches 1.5×10 -3 Pa, and heated to 450°C;

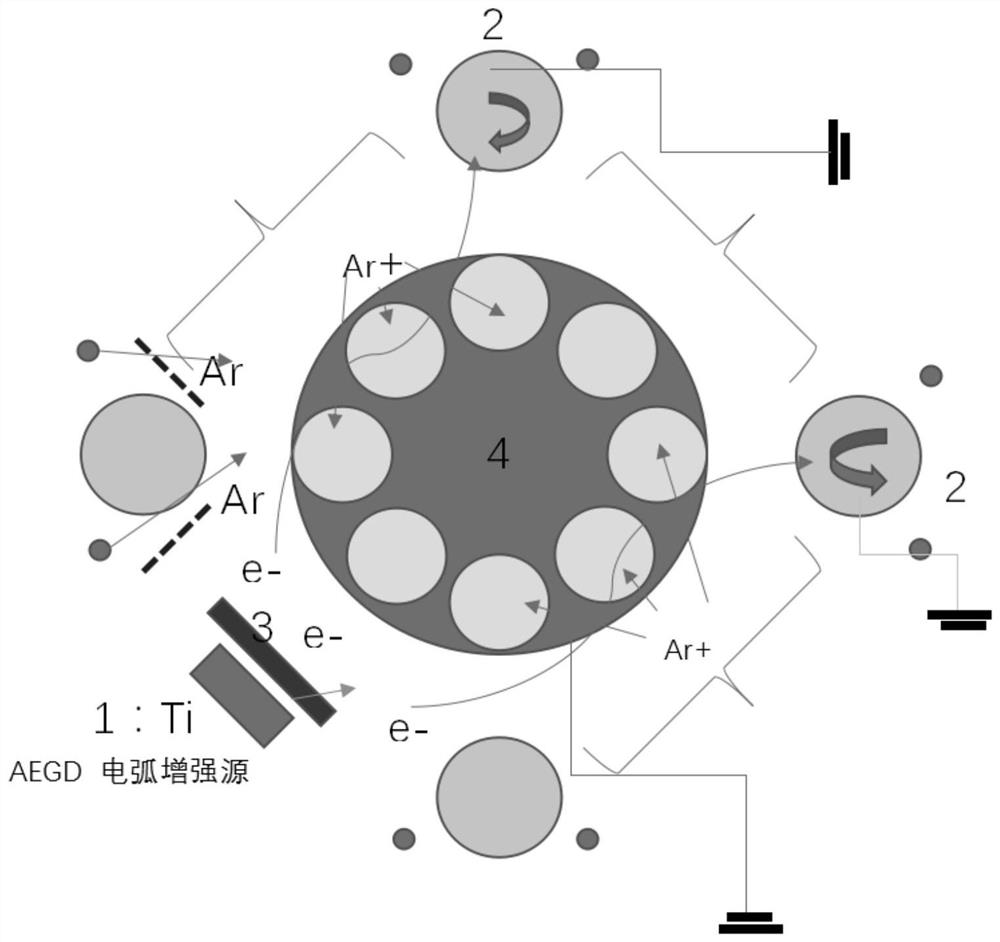

[0053] (4) Turn on the circular arc enhancement source 1, use Ti as the target source, and generate a large amount of titanium ions Ti after turning on + and e - , titanium ions are splashed on the front baffle plate 3 of the target to prevent contamination of the workpiece on the material tray 4 to be cleaned by ions;

[0054] (5) At the same time, the two arc enhancement targets 2 on the opposite side of the circular arc enhancement source are connected to the positive pole of the power supply 150V to attract a large number of generated electrons;

[0055]...

Embodiment 2

[0061] (1) Ultrasonic 40kHz to clean impurities on the surface of the plasma cemented carbide substrate, and install the furnace;

[0062] (2) Arc-enhanced argon ion bombardment in the vacuum coating equipment to remove impurities on the surface of the cemented carbide substrate;

[0063] (3) Vacuumize the vacuum chamber of the vacuum coating equipment, and the vacuum degree reaches 4.5×10 -3 Pa, and heated to 370°C;

[0064] (4) Turn on the circular arc enhancement source 1, use Ti as the target source, and generate a large amount of titanium ions Ti after turning on + and e - , titanium ions are splashed on the front baffle plate 3 of the target to prevent the workpiece to be cleaned on the material tray 4 from being polluted;

[0065] (5) At the same time, the two arc enhancement target positions 2 on the opposite side of the circular arc enhancement source are connected to the positive pole of the power supply 80V to attract a large number of generated electrons;

[00...

Embodiment 3

[0072] (1) Ultrasonic 40kHz to clean impurities on the surface of the plasma cemented carbide substrate, and install the furnace;

[0073] (2) Arc-enhanced argon ion bombardment in the vacuum coating equipment to remove impurities on the surface of the cemented carbide substrate;

[0074] (3) Vacuumize the vacuum chamber of the vacuum coating equipment, and the vacuum degree reaches 4.5×10 -3 Pa, and heated to 550°C;

[0075] (4) Turn on the circular arc enhancement source 1, use Ti as the target source, and generate a large amount of titanium ions Ti after turning on + and e - , titanium ions are splashed on the front baffle plate 3 of the target to prevent the workpiece to be cleaned on the material tray 4 from being polluted;

[0076] (5) At the same time, the two arc enhancement target positions 2 on the opposite side of the circular arc enhancement source are connected to the positive pole 40V of the power supply to attract a large number of generated electrons;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com