Method for softening water body and synchronously preparing calcium carbonate whiskers by adopting electrochemistry

A calcium carbonate whisker, electrochemical technology, applied in chemical instruments and methods, descaling and water softening, natural water treatment, etc., can solve problems that are not green cleaning technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

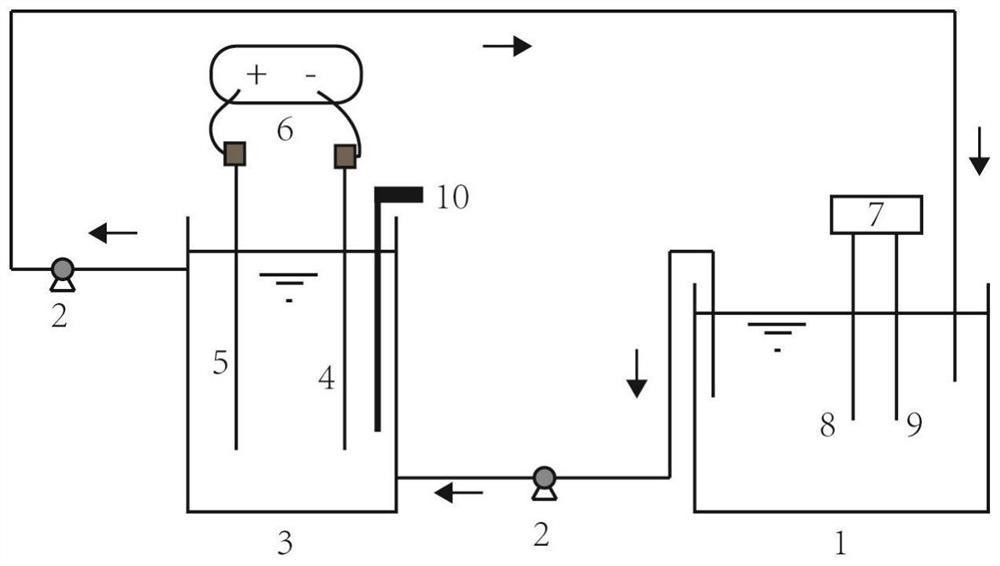

Method used

Image

Examples

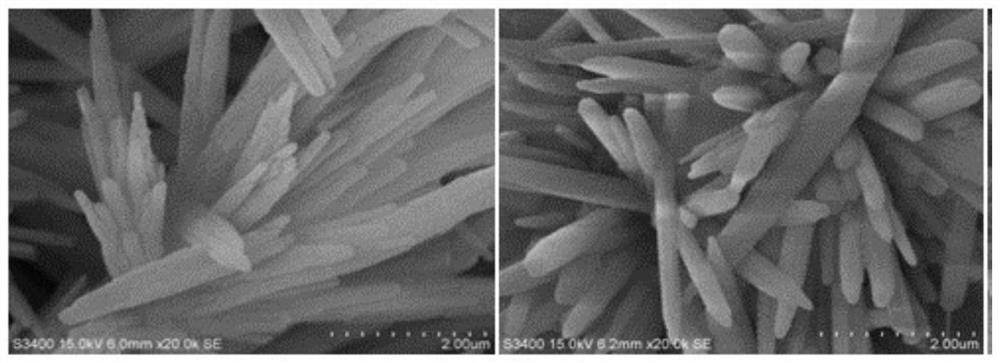

Embodiment 1

[0033] In this embodiment, a stainless steel mesh is used as the cathode 4, a ruthenium iridium titanium plate is used as the anode 5, and the distance between the cathode 4 and the anode 5 is 2.0 cm.

[0034] The components in the water sample to be treated containing calcium salt, magnesium salt and carbonate used in this embodiment are specifically: 0.3wt% soluble calcium chloride, 0.3wt% sodium bicarbonate, 0.1wt% magnesium chloride, see for details Table 1.

[0035] A method for softening water body and synchronously preparing calcium carbonate whiskers by electrochemistry, specifically comprising the following steps:

[0036](a) Take the untreated water sample containing calcium salt, magnesium salt and carbonate, add it to the electrolytic cell as an electrolyte solution, then put the cathode and anode in the electrolytic cell, and connect it with an external power supply to form an electrochemical reactor , and then pre-electrolyzed for 10 minutes at a temperature of ...

Embodiment 2

[0040] In this embodiment, a stainless steel mesh is used as the cathode 4, a ruthenium iridium titanium plate is used as the anode 5, and the distance between the cathode 4 and the anode 5 is 2.0 cm.

[0041] The components in the water sample to be treated containing calcium salt, magnesium salt and carbonate used in this embodiment are specifically: soluble calcium chloride 1wt%, sodium bicarbonate 1wt%, magnesium chloride 0.1wt%, see Table 1 for details .

[0042] A method for softening water body and synchronously preparing calcium carbonate whiskers by electrochemistry, specifically comprising the following steps:

[0043] (a) Take the untreated water sample containing calcium salt, magnesium salt and carbonate, add it to the electrolytic cell as an electrolyte solution, then put the cathode and anode in the electrolytic cell, and connect it with an external power supply to form an electrochemical reactor , and then pre-electrolyzed for 10 minutes at a temperature of 40...

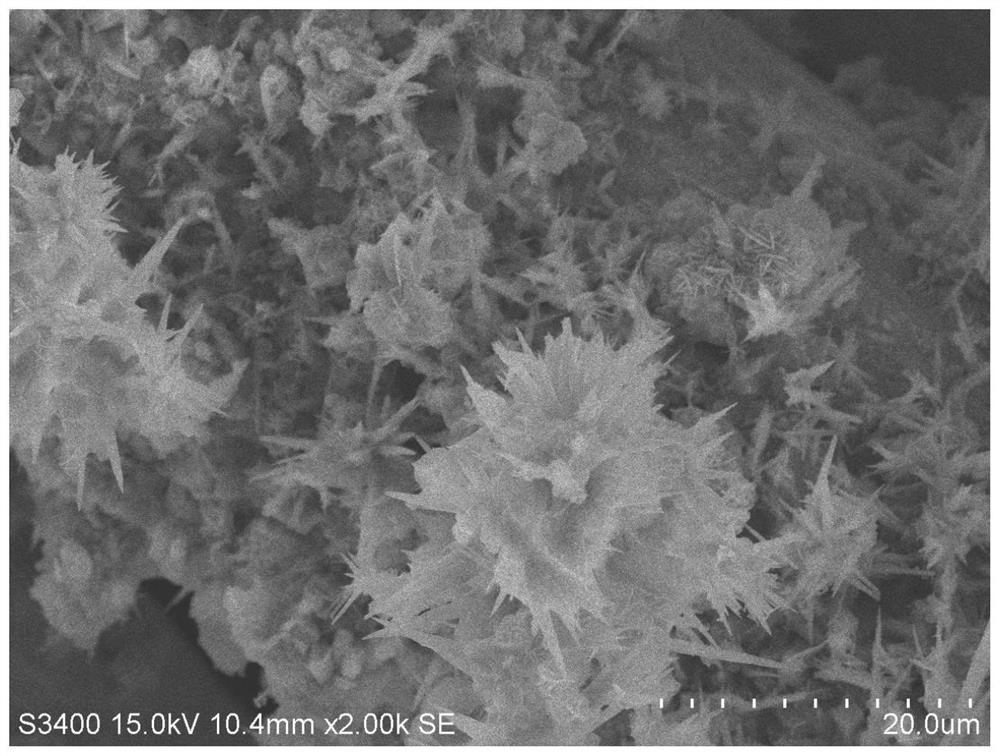

Embodiment 3

[0047] In this embodiment, a stainless steel mesh is used as the cathode 4, a ruthenium iridium titanium plate is used as the anode 5, and the distance between the cathode 4 and the anode 5 is 2.0 cm.

[0048] The components in the water sample to be treated containing calcium salt, magnesium salt and carbonate used in this embodiment are specifically: soluble calcium chloride 2wt%, sodium bicarbonate 2wt%, magnesium chloride 0.1wt%, see Table 1 for details .

[0049] A method for softening water body and synchronously preparing calcium carbonate whiskers by electrochemistry, specifically comprising the following steps:

[0050] (a) Take the untreated water sample containing calcium salt, magnesium salt and carbonate, add it to the electrolytic cell as an electrolyte solution, then put the cathode and anode in the electrolytic cell, and connect it with an external power supply to form an electrochemical reactor , and then pre-electrolyzed at a temperature of 50°C and a voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com