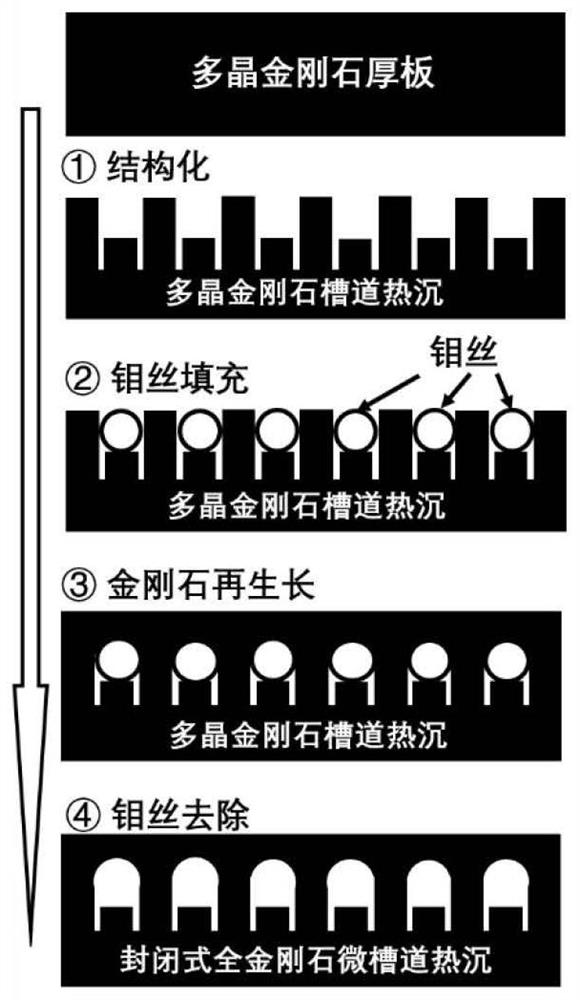

A preparation method of a closed all-diamond microchannel heat sink

A diamond and closed technology, applied in the direction of cooling/ventilation/heating modification, modification through conduction heat transfer, semiconductor/solid-state device components, etc., can solve the problem of limited application range of heat conduction, and achieve easy organization of internal heat exchange, High-quality, high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Using a graphite substrate with a diameter of 150mm coated with a titanium transition layer pretreated by diamond powder on the surface, a diamond thick plate was prepared by DC arc plasma jet CVD. Put the substrate into the vacuum chamber and pump it to the ultimate vacuum of 5×10 - 1 Pa, fill in argon gas gradually to 5.2kPa, set the arc ignition current of the plasma arc power supply to 135A, ignite the arc between the cathode and the anode, and fill in hydrogen gas (Ar:H 2 =0.8:1) The magnetic field coil is adjusted so that the arc rotates stably above the deposition substrate. At the same time, increase the plasma arc power supply current to 320A, so that the substrate temperature rises to 830°C, and CH is introduced according to the ratio of 8%. 4 Gas for diamond nucleation, the nucleation time is 30min, reducing CH 4 The gas ratio is increased to 5%, and the plasma arc power supply current is further increased so that the substrate temperature reaches 860°C, a...

Embodiment 2

[0043] Using a graphite substrate with a diameter of 120mm coated with a titanium transition layer pretreated by diamond powder on the surface, a diamond thick plate was prepared by DC arc plasma jet CVD. Put the substrate into the vacuum chamber and pump it to the ultimate vacuum of 5×10 - 1 Pa, fill in argon gas gradually to 5.2kPa, set the arc ignition current of the plasma arc power supply to 135A, ignite the arc between the cathode and the anode, and fill in hydrogen gas (Ar:H 2 =0.8:1) The magnetic field coil is adjusted so that the arc rotates stably above the deposition substrate. At the same time, increase the plasma arc power supply current to 320A, so that the substrate temperature rises to 830°C, and CH is introduced in proportion to 5%. 4 Gas for diamond nucleation, the nucleation time is 30min, reducing CH 4 The gas ratio is increased to 3%, and the plasma arc power supply current is further increased so that the substrate temperature reaches 880°C, and then e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com