Platinum-cobalt alloy catalyst for fuel cell, and preparation method thereof

A platinum-cobalt alloy, fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of insufficient reducing ability, alloying of Pt and transition metals, etc., to achieve fewer steps, half-wave potential and limit current density improvement , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

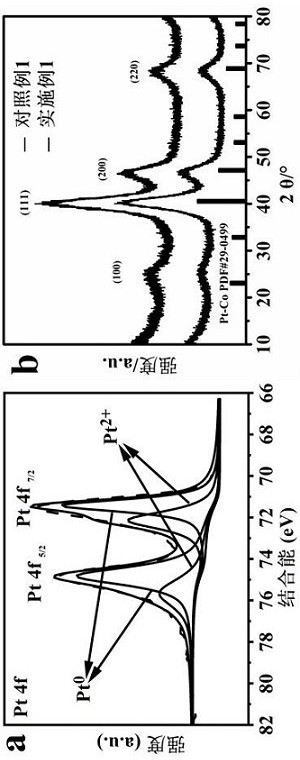

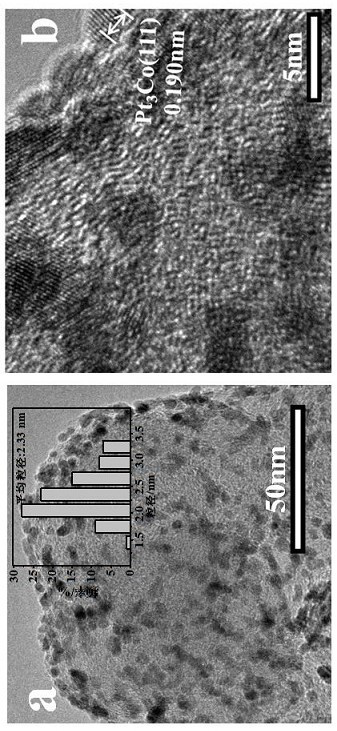

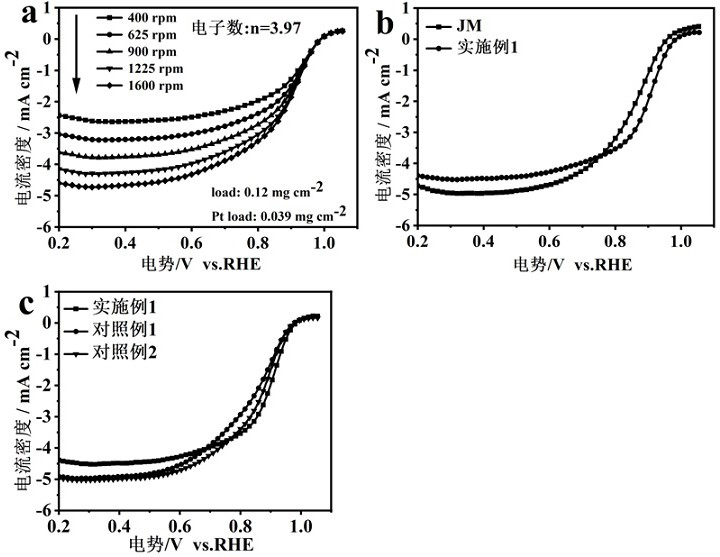

Embodiment 1

[0033] A platinum-cobalt alloy catalyst for a fuel cell and a preparation method thereof, comprising the steps of:

[0034] 1) Precursor dispersion: Weigh 120mg platinum acetylacetonate, 80mg XC-72, 281.1mg CoSO 4 ·7H 2 O, 20mgMn 2 (CO) 10 Put them into 50mL beakers respectively, add appropriate amount of ethylene glycol, and ultrasonically disperse for 30 minutes to obtain a uniform slurry;

[0035] 2) Catalyst synthesis: first add the XC-72 solution dispersed in step 1) into the flask, then add platinum acetylacetonate, CoSO 4 ·7H 2 O and Mn 2 (CO) 10 Add it dropwise to the XC-72 solution one by one, and react for 3 hours at 150°C in an oil bath;

[0036] 3) Catalyst separation: After cooling to room temperature, carry out centrifugal washing and drying, the centrifugal speed is 8000rpm, the centrifugal time is 5min, and vacuum drying is carried out at 60°C for 12h;

[0037]4) Catalyst pickling: add 0.5M H to the sample obtained in step 3) 2 SO 4 The solution was s...

Embodiment 2

[0060] A platinum-cobalt alloy catalyst for a fuel cell and a preparation method thereof, comprising the steps of:

[0061] 1) Precursor dispersion: The difference from Example 1 is that the Mn 2 (CO) 10 The addition amount is changed to 10 mg, and other steps are the same as step 1 of Example 1);

[0062] 2) Catalyst synthesis: same as step 2 of Example 1);

[0063] 3) Catalyst separation: same as step 3 of Example 1);

[0064] 4) Catalyst pickling: same as Step 4) of Example 1.

Embodiment 3

[0066] A platinum-cobalt alloy catalyst for a fuel cell and a preparation method thereof, comprising the steps of:

[0067] 1) Precursor dispersion: The difference from Example 1 is that the Mn 2 (CO) 10 The addition amount is changed to 30 mg, and other steps are the same as step 1 of Example 1);

[0068] 2) Catalyst synthesis: same as step 2 of Example 1);

[0069] 3) Catalyst separation: same as step 3 of Example 1);

[0070] 4) Catalyst pickling: same as Step 4) of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com