Purple sweet potato noodles with high anthocyanin preservation rate and making method thereof

A technology of purple potato noodles and a production method, which is applied in the functions of food ingredients, climate change adaptation, food heat treatment, etc., can solve problems such as low preservation rate, reduce starch polymerization degree, improve starch solubility, and ensure structure and color stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

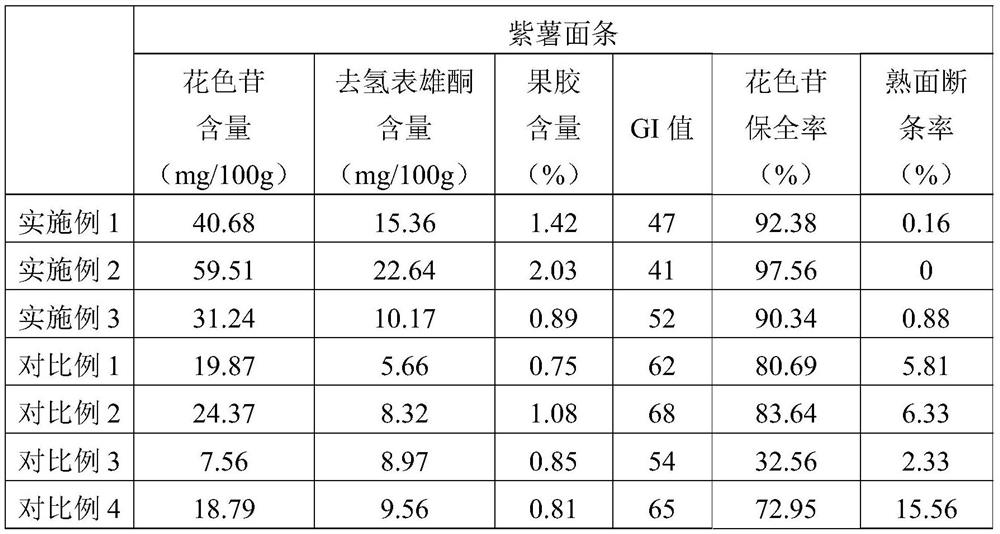

Examples

Embodiment 1

[0036] A method for making purple potato noodles with high anthocyanin preservation rate, comprising the following process steps:

[0037] S1: Preparation of purple sweet potato powder suspension

[0038] (1) Raw material pretreatment: After sorting, arranging, cleaning and peeling, fresh purple sweet potatoes are sliced to a thickness of 2 cm, treated under 1.6Mpa superheated steam for 60 seconds, taken out and cooled, and set aside.

[0039] (2) Preparation of purple sweet potato slurry: the purple sweet potato slices processed in step (1) are chopped and crushed to a volume average particle size of 50 μm, and the solid content is adjusted to 30%, sealed and packaged at 15°C, 500Mpa and processed After 50 minutes, stand at 5°C for 15 hours to obtain purple sweet potato slurry, which is set aside.

[0040] (3) primary fermentation: add 3% defatted silkworm chrysalis powder and 0.5% glucose to the purple sweet potato slurry obtained in step (2) by mass volume ratio, inocula...

Embodiment 2

[0054] A method for making purple potato noodles with high anthocyanin preservation rate, comprising the following process steps:

[0055] S1: Preparation of purple sweet potato powder suspension

[0056] (1) Raw material pretreatment: After sorting, arranging, cleaning and peeling fresh purple sweet potatoes, slice them to a thickness of 1.5cm, treat them under 1.5Mpa superheated steam for 80s, take them out and cool them, and set them aside.

[0057] (2) Preparation of purple sweet potato slurry: the purple sweet potato slices processed in step (1) are chopped and crushed to a volume average particle size of 80 μm, and the solid content is adjusted to 38%, sealed and packaged at 20°C and 700Mpa for processing After 60 minutes, stand at 10°C for 20 hours to obtain purple sweet potato slurry, which is set aside.

[0058] (3) primary fermentation: add 2% defatted silkworm chrysalis powder and 0.3% glucose to the purple sweet potato slurry obtained in step (2) by mass volume ra...

Embodiment 3

[0072] A method for making purple potato noodles with high anthocyanin preservation rate, comprising the following process steps:

[0073] S1: Preparation of purple sweet potato powder suspension

[0074] (1) Raw material pretreatment: After sorting, arranging, cleaning and peeling, fresh purple sweet potatoes are sliced to a thickness of 1 cm, treated under 1.2Mpa superheated steam for 90 seconds, taken out and cooled, and set aside.

[0075] (2) Preparation of purple sweet potato slurry: the purple sweet potato slices processed in step (1) are chopped and crushed to a volume average particle size of 100 μm, and the solid content is adjusted to 40%, sealed and packaged at 25°C and 200Mpa for processing After 30 minutes, stand at 15°C for 8 hours to obtain purple sweet potato slurry, which is set aside.

[0076] (3) Primary fermentation: add 1% defatted silkworm chrysalis powder and 0.2% glucose to the purple sweet potato slurry obtained in step (2) by mass volume ratio, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com