Composite separation membrane with conductivity and preparation method thereof

A separation membrane and conductivity technology, which is applied in the field of polymer separation membrane surface modification, to achieve the effect of simple process, easy large-scale industrial application, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

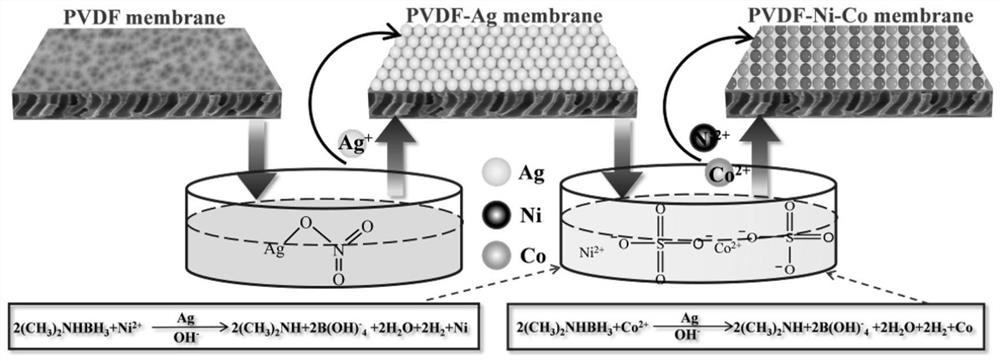

[0035] refer to figure 1 As shown, add 240mL ethylene glycol to a clean beaker, then add 8.5g NaOH, 0.3g AgNO 3 Add in ethylene glycol, stir to make it fully dissolve and evenly, to obtain a mixed solution; put a clean polyvinylidene fluoride (PVDF) diaphragm (5 × 5cm 2 ) into the mixed solution in the beaker, and left to stand for 60s, it can be observed that the PVDF film gradually changes from white to brownish yellow, which indicates that the preparation of the PVDF-Ag film is complete, and the coating of silver is conducive to the next step of the reaction. Subsequently, the PVDF-Ag membrane was washed with deionized water and dried naturally. Next, by successively adding 14g NiSO 4 ·6H 2 O, 14g CoSO 4 ·7H 2 O, 42gC 4 h 4 KNaO 6 4H 2 O, 5.8 g Na 3 C 6 h 5 o 7 and 1g C 2 h 10 BN was dissolved in 900 mL deionized water, and ammonia water was used as a buffer to adjust the pH to 10 to prepare a cobalt-nickel reducing solution. Immerse the PVDF-Ag membrane in ...

Embodiment 2

[0041] Add 240mL ethylene glycol to a clean beaker, then add 7.5g NaOH, 0.28g AgNO 3 Add in ethylene glycol, stir to make it fully dissolve and evenly, to obtain a mixed solution; put a clean polyvinylidene fluoride (PVDF) diaphragm (5 × 5cm 2 ) into the mixed solution of the beaker, and left to stand for 90s, it can be observed that the PVDF film gradually changes from white to brownish yellow, which indicates that the preparation of the PVDF-Ag film is complete, and the coating of silver is conducive to the next step of the reaction. Subsequently, the PVDF-Ag membrane was washed with deionized water and dried naturally. Next, by successively adding 10g NiSO 4 ·6H 2 O, 10g CoSO 4 ·7H 2 O, 45g C 4 h 4 KNaO 6 4H 2 O, 10g Na 3 C 6 h 5 o 7 and 1.5g C 2 h 10 BN was dissolved in 900 mL deionized water, and ammonia water was used as a buffer to adjust the pH to 10 to prepare a cobalt-nickel reducing solution. Immerse the PVDF-Ag membrane in the cobalt-nickel reducing ...

Embodiment 3

[0044] Add 240mL ethylene glycol to a clean beaker, then add 9.5g NaOH, 0.35g AgNO 3 Add in ethylene glycol, stir to make it fully dissolve and evenly, to obtain a mixed solution; put a clean polyvinylidene fluoride (PVDF) diaphragm (5 × 5cm 2 ) into the mixed solution in the beaker, and let it stand for 120s. It can be observed that the PVDF film gradually changes from white to brownish yellow, which indicates that the preparation of the PVDF-Ag film is completed, and the coating of silver is conducive to the next step of the reaction. Subsequently, the PVDF-Ag membrane was washed with deionized water and dried naturally. Next, by sequentially adding 18g NiSO 4 ·6H 2 O, 18g CoSO 4 ·7H 2 O, 50g C 4 h 4 KNaO 6 4H 2 O, 5g Na 3 C 6 h 5 o 7 and 2g C 2 h 10 BN was dissolved in 900 mL deionized water, and ammonia water was used as a buffer to adjust the pH to 10 to prepare a cobalt-nickel reducing solution. Immerse the PVDF-Ag membrane in the cobalt-nickel reducing so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com