Multifunctional metal-ceramic composite material and preparation method thereof

A ceramic composite material and composite material technology, applied in the field of multifunctional metal-ceramic composite materials and its preparation, can solve the problems of single composition and function, and achieve the effects of good fluidity, high tap density and small composition segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] In a specific embodiment, the preparation method includes the following steps:

[0056] (1) Ingredients - Mixing - Drying

[0057] Ti(CN), TiB in micron 2 , Metals (three or more of Ni, Co, Cr, Ti, Fe) are used as raw materials, and weighed according to a certain proportion, and then the raw material powder is wet-milled. The wet grinding medium is absolute ethanol or acetone, and the mixed slurry obtained by wet grinding is dried to obtain a dried mixture.

[0058] (2) spheroidization of the mixture

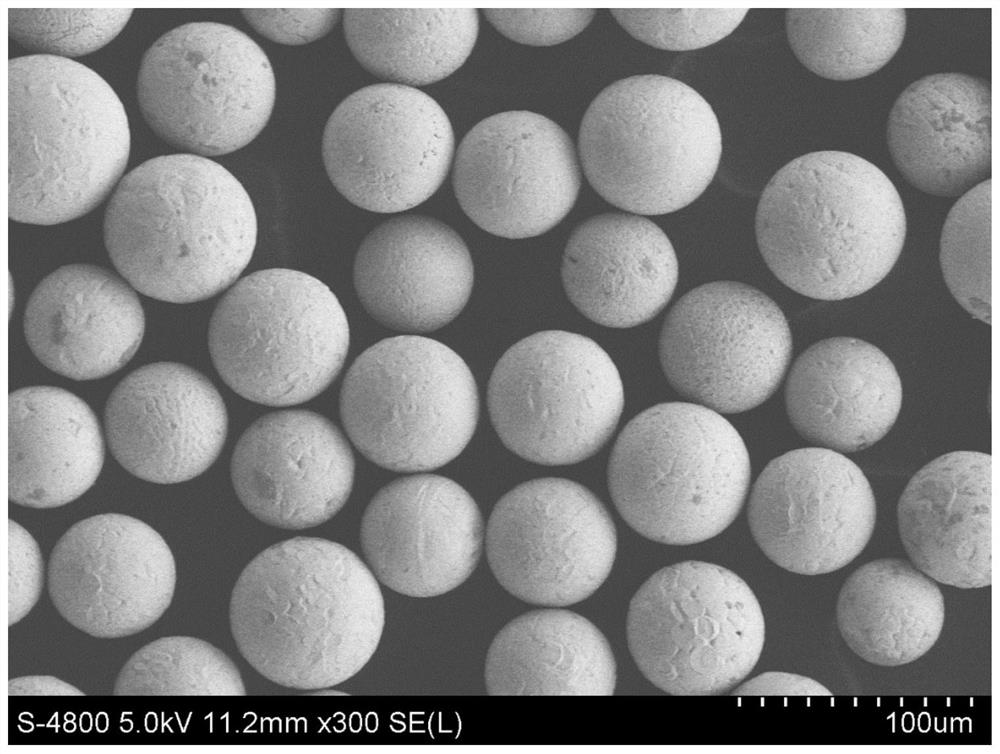

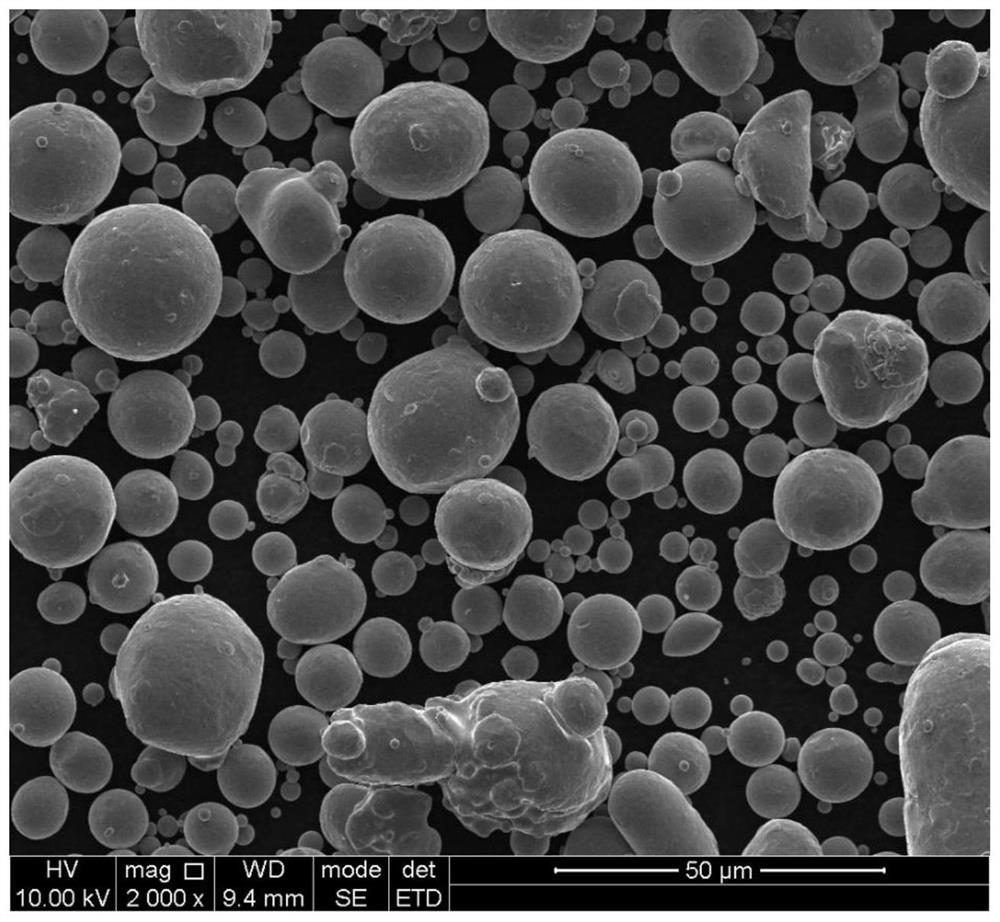

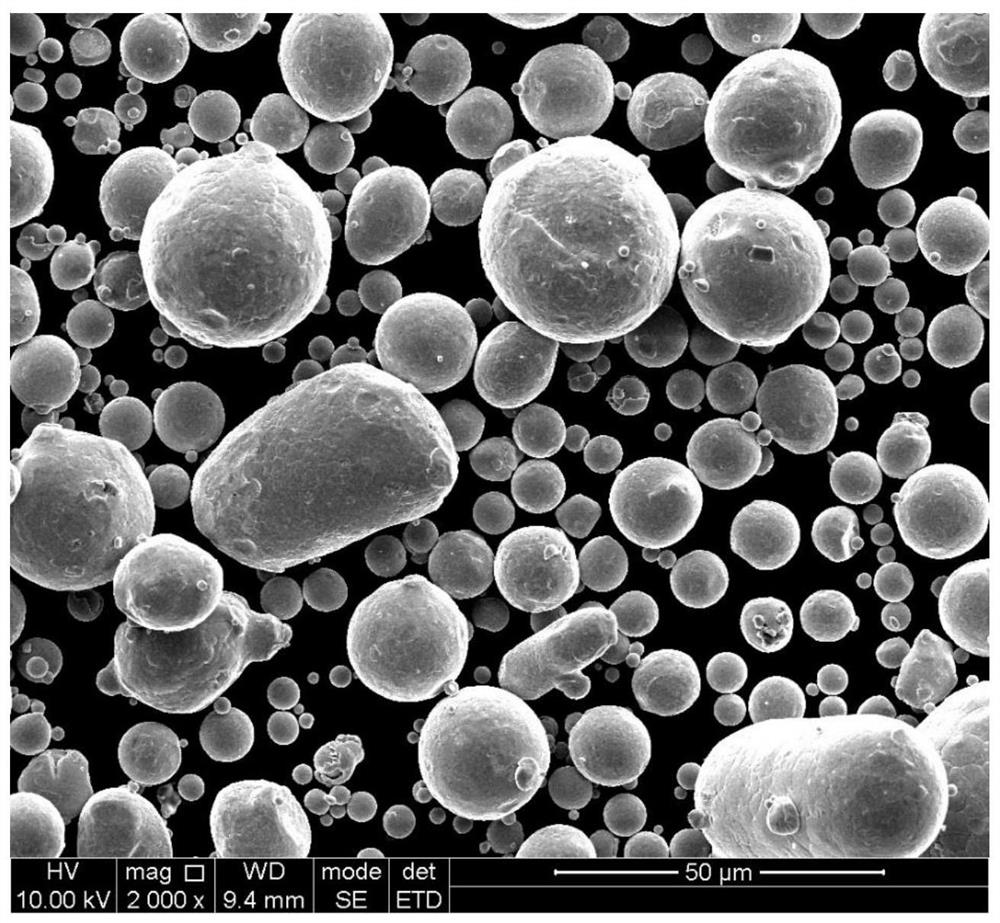

[0059] After adding a certain amount of molding agent to the drying mixture obtained in step (1) and mixing it evenly, it is sent to a spheroidizing drum device for spheroidization, and then sieved to remove spherical powder with a particle size greater than 30 mesh and less than 200 mesh, which is obtained Spherical or spherical mixed powder with uniform particle size distribution.

[0060] (3) Vacuum sintering treatment

[0061] Place the quasi-spherical or spheric...

Embodiment 1

[0090] (1) Ingredients - Mixing - Drying

[0091] Ti(CN), TiB in micron 2 , Ni, Co, Cr, Ti, Fe are raw materials, weigh each raw material powder by the following mass percentages: Ti (CN) is 35%, TiB 2 30% for Ni, 5% for Co, 5% for Cr, 3% for Ti, and 17% for Fe. The weighed raw material powder is wet-milled, the wet-milling medium is absolute ethanol, and the mixed slurry obtained from the wet-milling is vacuum-dried to obtain a dried mixture.

[0092] (2) spheroidization of the mixture

[0093] After adding the polyethylene glycol with a mass fraction of 5.0% of the total mass of the mixture in the drying mixture obtained in step (1) and mixing evenly, the mixed powder is sent to a spheroidizing drum device for spheroidization, and then sieved to remove the particle size Spherical powder larger than 30 mesh and smaller than 200 mesh can obtain spherical or spherical mixed powder with uniform particle size distribution; the wall of the drum is a jacket structure. It is 10r...

Embodiment 2

[0097] (1) Ingredients - Mixing - Drying

[0098] Ti(CN), TiB in micron 2 , Ni, Co, Cr, Ti, Fe are raw materials, weigh each raw material powder by the following mass percentages: Ti (CN) is 30%, TiB 2 40% for Ni, 9% for Ni, 5% for Co, 5% for Ti, 1% for Cr, and 10% for Fe. The weighed raw material powder is wet-milled, and the wet-milling medium is anhydrous ethanol, and the amount of anhydrous ethanol is limited to the mixed slurry obtained after wet-milling, and the mixed slurry obtained by wet-milling is vacuum-dried to obtain a dried mixed slurry. material.

[0099] (2) spheroidization of the mixture

[0100] After adding the paraffin wax with a mass fraction of 4.0% of the total amount of the mixture in the drying mixture obtained in step (1), after mixing evenly, the mixed powder is sent to a spheroidizing drum device for spheroidization, and then sieved to remove particles with a particle size greater than 30 mesh. And less than 200 mesh spherical powder, that is, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com