Surface treatment method of zirconium-based ternary amorphous alloy

An amorphous alloy and surface treatment technology, applied in the field of materials, can solve problems such as the performance degradation of zirconium-based amorphous alloys, limit the service range of zirconium-based ternary amorphous alloys, affect the internal structure and composition of alloys, and achieve excellent mechanical properties , good glass forming ability, and the effect of improving surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

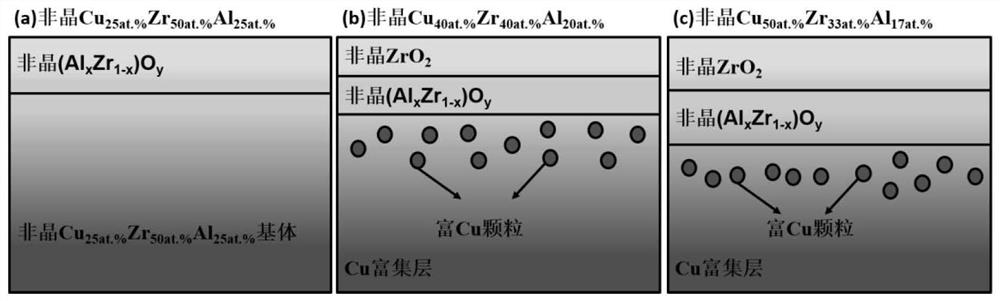

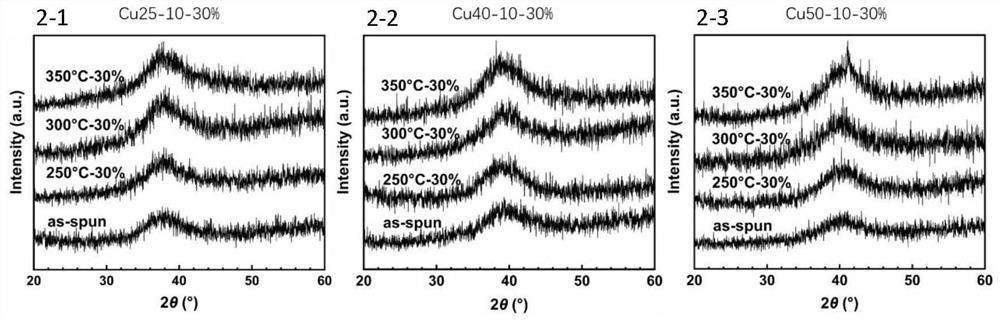

[0036] Amorphous alloy Cu 25at.% Zr 50at.% al 25at.% Carry out phase identification to confirm that it is amorphous, such as diagram 2-1 shown. Put the sample in acetone, clean it with an ultrasonic cleaner for 1 minute, then take the sample out and put it in alcohol to continue ultrasonic cleaning for 1 minute, and finally blow dry the surface of the sample with dry compressed nitrogen. Afterwards, put the sample into a tube furnace that has been heated to 250°C in advance, inject high-temperature oxygen with a water content of 1vol.%, the oxygen flow rate is 10ml / min, and the steam heating temperature is 100°C. After constant temperature for 1 hour, take it out for cooling . can be formed on amorphous surfaces such as figure 1 The oxide layer structure shown in (a), which protects the inner matrix well, and the passivation behavior can effectively prevent further oxidation of the alloy.

Embodiment 2

[0038] Amorphous alloy Cu 25at.% Zr 50at.% al 25at.% Carry out phase identification to confirm that it is amorphous, such as diagram 2-1 shown. Put the sample in acetone, clean it with an ultrasonic cleaner for 1 minute, then take the sample out and put it in alcohol to continue ultrasonic cleaning for 10 minutes, and finally blow dry the surface of the sample with dry compressed nitrogen. Afterwards, put the sample into a tube furnace heated to 250°C in advance, feed high-temperature oxygen with a water content of 10vol.%, the oxygen flow rate is 100ml / min, and the steam heating temperature is 100°C. After 5 hours of constant temperature, take it out for cooling . can be formed on amorphous surfaces such as figure 1 The oxide layer structure shown in (a), which protects the inner matrix well, and the passivation behavior can effectively prevent further oxidation of the alloy.

Embodiment 3

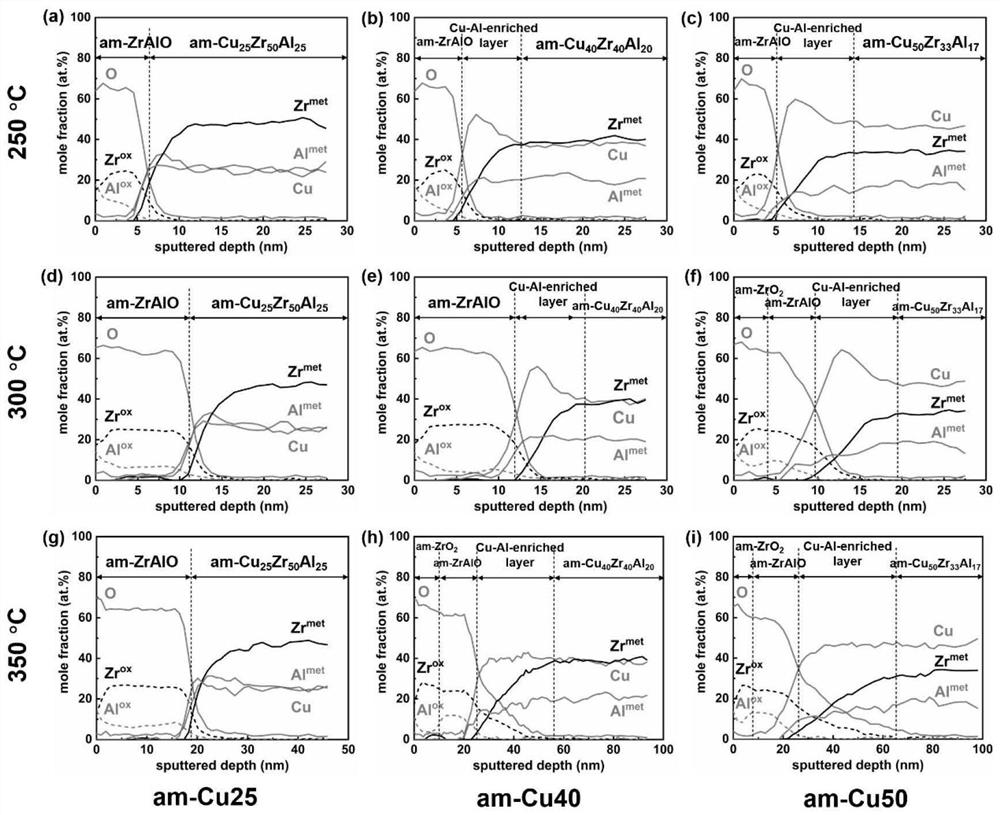

[0040] Amorphous alloy Cu 25at.% Zr 50at.% al 25at.% Carry out phase identification to confirm that it is amorphous, such as diagram 2-1 shown. Put the sample in acetone, clean it with an ultrasonic cleaner for 1 minute, then take the sample out and put it in alcohol to continue ultrasonic cleaning for 15 minutes, and finally blow dry the surface of the sample with dry compressed nitrogen. Afterwards, put the sample into a tube furnace that has been heated to 250°C in advance, feed high-temperature oxygen with a water content of 30vol.%, the oxygen flow rate is 200ml / min, and the steam heating temperature is 110°C. After 10 hours of constant temperature, take it out for cooling . diagram 2-1 The XRD phase analysis of the sample after wet oxidation at 250°C for 10 hours shows that both the oxide layer and the alloy are amorphous. The element content distribution in the depth direction of the sample after oxidation is as follows: image 3 As shown in (a), it shows that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com