Design for improving stability of perovskite solar cell module

A technology of solar cells and battery modules, applied in the field of solar cells, can solve the problems of reduced module stability, increased parallel resistance, increased leakage current, etc., to achieve improved stability, high open circuit voltage and fill factor, and reduced leakage current Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

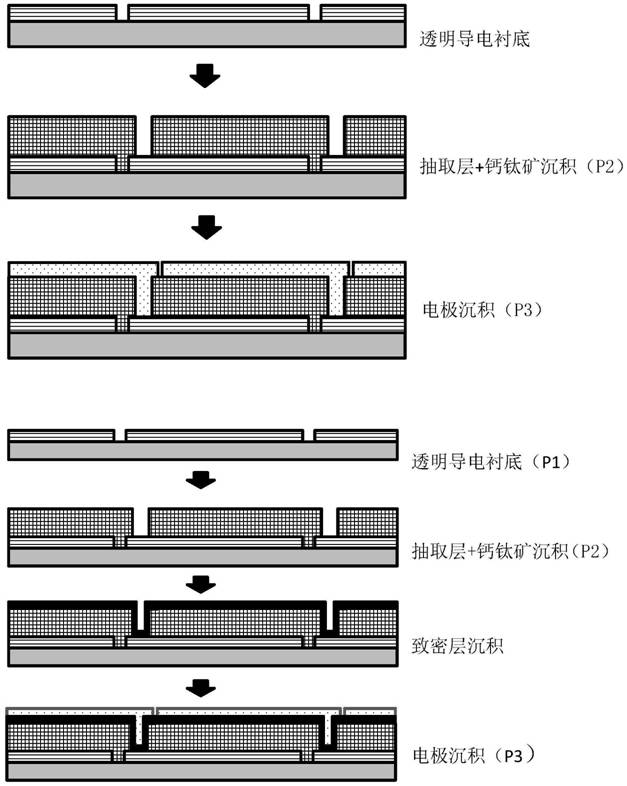

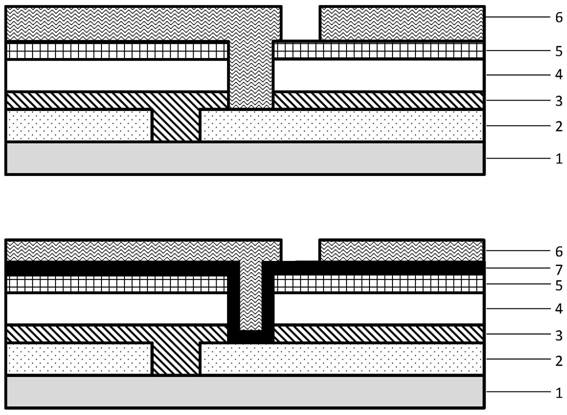

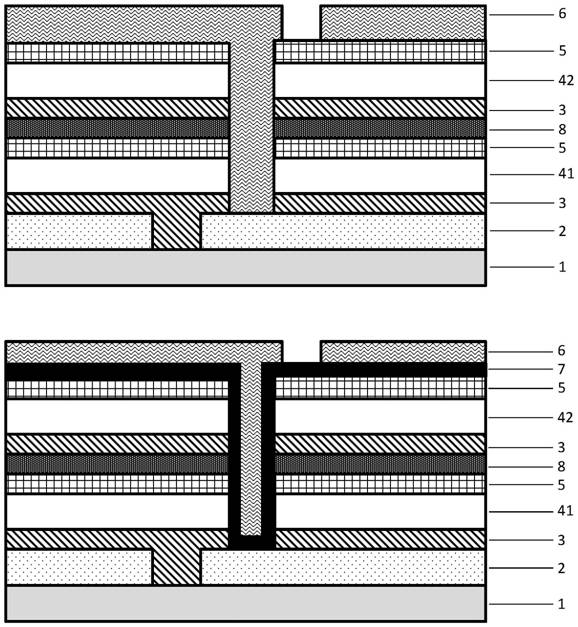

[0030]As an embodiment of the present invention, the battery module is divided into single-junction, double-junction stack and triple-junction stack; the single-junction battery module sequentially includes a conductive transparent substrate, A hole extraction layer 3, a perovskite layer 4, an electron extraction layer 5, a dense layer 7 and an electrode 6; the conductive transparent substrate sequentially includes a glass 1 and a transparent conductive film 2 from the light-receiving front to the light-receiving back; the double junction The battery module sequentially includes a transparent conductive substrate, a hole extraction layer 3, a wide-bandgap perovskite 41, an electron extraction layer 5, a tunneling composite layer 8, a hole extraction layer 3, and a narrow-bandgap calcium layer from the light-receiving front to the light-receiving back. The titanium ore 42, the electron extraction layer 5, the dense layer 7 and the electrode 6; the three-junction battery module s...

Embodiment 1

[0044] This Example 1 adopts figure 2 A large-area perovskite single-junction solar cell module is fabricated with the structure shown, and the specific fabrication process is as follows:

[0045] 1. Use laser to etch about 100um line width on the cleaned ITO substrate, which is P1.

[0046] 2. A layer of poly[bis(4-phenyl)(2,4,6-trimethylphenyl)amine] (PTAA) with a thickness of about 20 nm is used as the hole extraction layer.

[0047] 3. Deposit a layer of perovskite on the hole extraction layer with a thickness of about 300 nm.

[0048] 4. A layer of fullerene (C 60 ) as an electron extraction layer with a thickness of about 25 nm.

[0049] 5. A layer of 2,9-dimethyl-4,7-biphenyl-1,10-phenanthroline (BCP) was deposited by thermal evaporation with a thickness of about 7 nm.

[0050] 6. The line width of about 100um is used for laser etching, which is P2.

[0051] 7. Finally, a layer of Cu with a thickness of 150 nm was deposited by thermal evaporation as the conductive...

Embodiment 2

[0055] This embodiment 2 adopts figure 2 A large-area perovskite / perovskite tandem solar cell module group was prepared with the shown structure. The specific preparation process is as follows:

[0056] 1. Use laser to etch about 100um line width on the cleaned ITO substrate, which is P1.

[0057] 2. A layer of poly[bis(4-phenyl)(2,4,6-trimethylphenyl)amine] (PTAA) with a thickness of about 20 nm is used as the hole extraction layer.

[0058] 3. Deposit a layer of perovskite on the hole extraction layer with a thickness of about 300 nm.

[0059] 4. A layer of fullerene (C 60 ) as an electron extraction layer with a thickness of about 25 nm.

[0060] 5. Atomic layer deposition grows a layer of SnO 2 As a dense layer that hinders the diffusion of perovskite, the thickness is about 20 nm.

[0061] 6. The line width of about 100um is used for laser etching, which is P2.

[0062] 7. Finally, a layer of Cu with a thickness of 150 nm was deposited by thermal evaporation as the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com